Silicon carbide (SiC) otu ihe kristal nwere nnukwu oghere obosara (~ Si 3 ugboro), ịdị elu nke thermal conductivity (~ Si 3.3 ugboro ma ọ bụ GaAs ugboro 10), ọnụego mgbanwe saturation elektrọn dị elu (~ Si 2.5 ugboro), ọkụ eletrik dị elu. ubi (~ Si ugboro 10 ma ọ bụ GaAs 5 ugboro) na njirimara ndị ọzọ pụtara ìhè.

Ọgbọ nke atọ semiconductor ihe tumadi gụnyere SiC, GaN, diamond, wdg, n'ihi na ya band ọdịiche obosara (Eg) karịrị ma ọ bụ hà 2.3 electron volts (eV), makwaara dị ka wide band gap semiconductor ihe. E jiri ya tụnyere nke mbụ na nke abụọ ọgbọ semiconductor ihe, ọgbọ nke atọ semiconductor ihe nwere uru nke elu thermal conductivity, elu mmebi eletriki, elu juputara eletrọn Mbugharị ọnụego na elu bonding ike, nke nwere ike izute ọhụrụ chọrọ nke ọgbara ọhụrụ technology electronic maka elu. okpomọkụ, ike dị elu, nrụgide dị elu, ugboro ugboro na nguzogide radieshon na ọnọdụ ndị ọzọ siri ike. Ọ nwere atụmanya ngwa dị mkpa na mpaghara nchekwa mba, ụgbọ elu, ikuku ikuku, nyocha mmanụ, nchekwa anya, wdg, ma nwee ike belata ọnwụ ike karịa 50% n'ọtụtụ ụlọ ọrụ dị mkpa dị ka nkwukọrịta brọdband, ike anyanwụ, nrụpụta ụgbọ ala, semiconductor ọkụ, na smart grid, ma nwee ike ibelata olu akụrụngwa karịa 75%, nke bụ ihe dị mkpa maka mmepe sayensị na teknụzụ mmadụ.

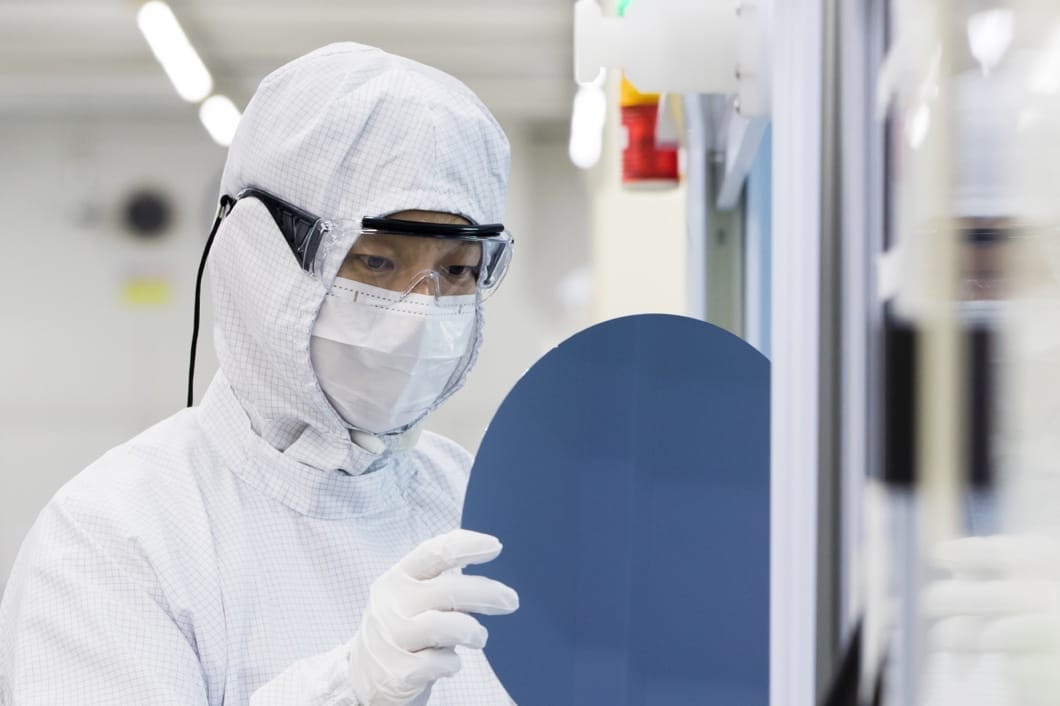

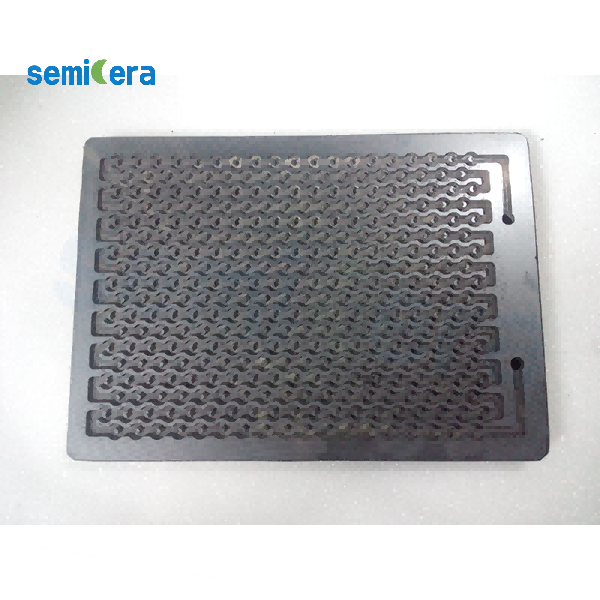

Ike Semicera nwere ike inye ndị ahịa ihe nrụpụta dị elu (Conductive), Semi-insulating (Semi-insulating), HPSI (High Purity Semi-insulating) silicon carbide substrate; Na mgbakwunye, anyị nwere ike inye ndị ahịa akwụkwọ mpempe akwụkwọ silicon carbide dị iche iche na nke dị iche iche; Anyị nwekwara ike hazie mpempe akwụkwọ epitaxial dị ka mkpa ndị ahịa si dị, ọ nweghịkwa ọnụọgụ kacha nta.

| Ihe | Mmepụta | Nyocha | Dummy |

| kristal Parameters | |||

| Ụdị poly | 4H | ||

| Njehie nhazi ihu elu | <11-20>4±0.15° | ||

| Igwe ọkụ eletrik | |||

| Dopant | n-ụdị Nitrogen | ||

| Nguzogide | 0.015-0.025ohm·cm | ||

| Mechanical Parameters | |||

| Dayameta | 150.0 ± 0.2mm | ||

| Ọkpụrụkpụ | 350± 25 μm | ||

| Ntuzi aka dị larịị | [1-100]±5° | ||

| Ogologo larịị nke isi | 47.5 ± 1.5mm | ||

| Ụlọ nke abụọ | Ọ dịghị | ||

| TTV | ≤5 μm | ≤10 μm | ≤15 μm |

| LTV | ≤3 μm (5mm*5mm) | ≤5 μm (5mm*5mm) | ≤10 μm (5mm*5mm) |

| Ụta | -15μm ~ 15μm | -35μm ~ 35μm | -45μm ~ 45μm |

| Warp | ≤35 μm | ≤45 μm | ≤55 μm |

| Ihu (Si-face) adịghị ike (AFM) | Ra≤0.2nm (5μm*5μm) | ||

| Nhazi | |||

| Njupụta Micropipe | <1 ea/cm2 | <10 nkea/cm2 | <15 ea/cm2 |

| Igwe adịghị ọcha | ≤5E10atom/cm2 | NA | |

| BPD | ≤1500 ea/cm2 | ≤3000 ea/cm2 | NA |

| TSD | ≤500 ea/cm2 | ≤1000 ea/cm2 | NA |

| Ogo ihu | |||

| N'ihu | Si | ||

| Ngwucha elu | Si-ihu CMP | ||

| Ụmụ irighiri ihe | ≤60ea/wafer (nha≥0.3μm) | NA | |

| Ọkpụkpụ | ≤5ea/mm. Ogologo ngụkọta ≤ Dayameta | Ogologo ngụkọta ≤2* dayameta | NA |

| Peel oroma / olulu / ntụpọ / striations / mgbawa / mmetọ | Ọ dịghị | NA | |

| Iberibe ibe / indents / mgbaji / hex | Ọ dịghị | ||

| Mpaghara polytype | Ọ dịghị | Mpaghara mkpokọta≤20% | Mpaghara mkpokọta≤30% |

| Akara laser n'ihu | Ọ dịghị | ||

| Ogo azụ | |||

| Ngwunye azụ | C-ihu CMP | ||

| Ọkpụkpụ | ≤5ea/mm, Mgbakọ ogologo≤2* dayameta | NA | |

| Nrụrụ azụ (nkịta ihu/indents) | Ọ dịghị | ||

| Azụ isi ike | Ra≤0.2nm (5μm*5μm) | ||

| Akara laser azụ | 1 mm (si n'akụkụ elu) | ||

| Ọnụ | |||

| Ọnụ | Chamfer | ||

| Nkwakọ ngwaahịa | |||

| Nkwakọ ngwaahịa | Epi dị njikere na nkwakọ ihe efu Ngwunye cassette ọtụtụ wafer | ||

| * Ihe edeturu: "NA" pụtara enweghị arịrịọ Ihe anaghị ekwupụta nwere ike na-ezo aka na SEMI-STD. | |||