Silicon carbide (SiC) epitaxy

Tray epitaxial, nke na-ejide mkpụrụ SiC maka itolite iberi nke SiC epitaxial, etinyere n'ime ụlọ mmeghachi omume wee kpọtụrụ wafer ozugbo.

The elu ọkara-ọnwa akụkụ bụ a na-ebu ndị ọzọ ngwa nke mmeghachi omume ụlọ nke Sic epitaxy akụrụngwa, mgbe ala ọkara ọnwa akụkụ na-ejikọta na quartz tube, ewebata gas na-anya susceptor isi bugharia. ha na-achịkwa okpomọkụ ma tinye ya n'ime ụlọ mmeghachi omume na-enweghị kọntaktị kpọmkwem na wafer.

Nke epitaxy

Tray ahụ, nke na-ejide mkpụrụ Si maka itolite iberi Si epitaxial, tinye ya n'ọnụ ụlọ mmeghachi omume wee kpọtụrụ wafer ozugbo.

Mgbanaka na-ekpo ọkụ dị na mgbanaka mpụta nke Si epitaxial substrate tray ma ejiri ya mee ihe maka nhazi na kpo oku. A na-etinye ya na ụlọ mmeghachi omume ma ghara ịkpọtụrụ wafer ozugbo.

Ihe susceptor nke epitaxial, nke na-ejide mkpụrụ Si maka itolite iberi nke Si epitaxial, na-etinye ya n'ime ụlọ mmeghachi omume ma na-akpọtụrụ wafer ozugbo.

Epitaxial barrel bụ isi ihe eji eme ihe na usoro nrụpụta semiconductor dị iche iche, nke a na-ejikarị na akụrụngwa MOCVD, yana nkwụsi ike ọkụ dị mma, nguzogide kemịkalụ na iyi nguzogide, dabara adaba maka ojiji na usoro okpomọkụ dị elu. Ọ na-akpọtụrụ wafers.

| Njirimara anụ ahụ nke Silicon Carbide recrystallized | |

| Ngwongwo | Uru a na-ahụkarị |

| Okpomọkụ na-arụ ọrụ (°C) | 1600°C (ya na oxygen), 1700°C (mbelata gburugburu ebe obibi) |

| SiC ọdịnaya | > 99.96% |

| Ọdịnaya Si efu | <0.1% |

| Nnukwu njupụta | 2.60-2.70 g / cm3 |

| Porosity pụtara | <16% |

| Ike mkpakọ | > 600 MPa |

| Ike na-ehulata oyi | 80-90 MPa (20°C) |

| Ike na-ehulata ọkụ | 90-100 MPa (1400°C) |

| Mgbasa ọkụ @1500°C | 4,70 10-6/°C |

| Nrụpụta okpomọkụ @1200°C | 23 W/m•K |

| Modulu nke na-agbanwe agbanwe | 240 GPA |

| Mgbochi ujo okpomọkụ | Dị oke mma |

| Njirimara anụ ahụ nke Sintered Silicon Carbide | |

| Ngwongwo | Uru a na-ahụkarị |

| Ngwakọta kemịkalụ | SiC> 95%, Si <5% |

| Njupụta nnukwu | > 3.07 g/cm³ |

| Porosity pụtara | <0.1% |

| Modul nke mgbawa na 20 ℃ | 270 MPa |

| Modul nke mgbawa na 1200 ℃ | 290 MPa |

| Isi ike na 20 ℃ | 2400kg/mm² |

| Mgbaji siri ike na 20% | 3.3 MPa · m1/2 |

| Thermal Conductivity na 1200 ℃ | 45 w/m .K |

| Mgbasa ọkụ na 20-1200 ℃ | 4.5 1 × 10 -6/ ℃ |

| Oke.arụ ọrụ okpomọkụ | 1400 ℃ |

| Thermal ujo eguzogide na 1200 ℃ | Ọ dị mma |

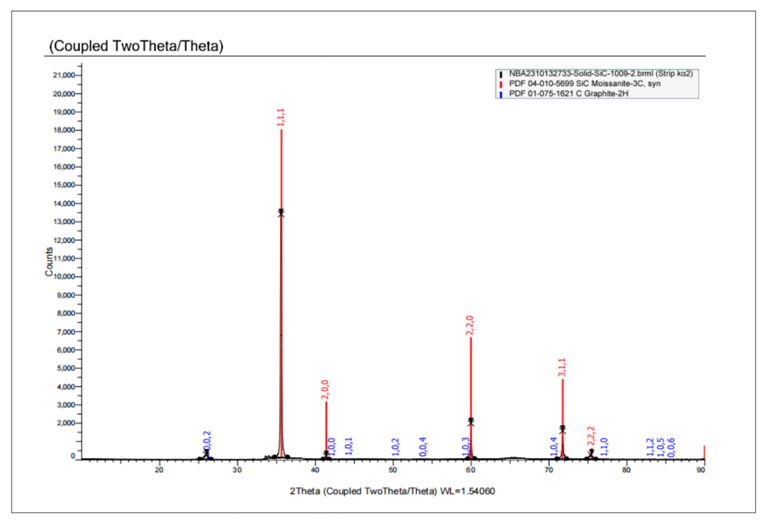

| Njirimara anụ ahụ bụ isi nke ihe nkiri CVD SiC | |

| Ngwongwo | Uru a na-ahụkarị |

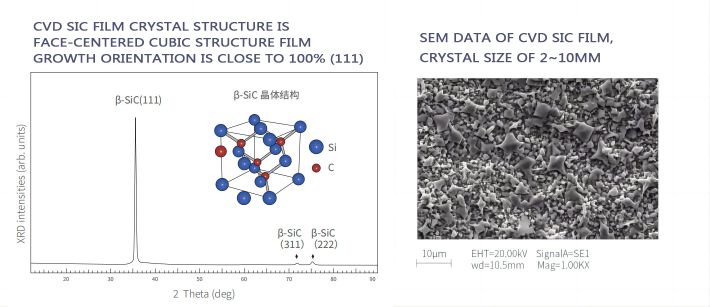

| Ọdịdị kristal | FCC β oge polycrystalline, tumadi (111) gbakwasara |

| Njupụta | 3.21g/cm³ |

| Ike 2500 | (500 g ibu) |

| Nha ọka | 2 ~ 10μm |

| Ịdị ọcha kemịkalụ | 99.99995% |

| Ike ikpo ọkụ | 640 nk-1· K-1 |

| Sublimation okpomọkụ | 2700 ℃ |

| Ike Flexural | 415 MPa RT 4-isi |

| Modul nke Young | 430 Gpa 4pt ekwe, 1300 ℃ |

| Nrụpụta okpomọkụ | 300W·m-1· K-1 |

| Mgbasa ọkụ (CTE) | 4.5 × 10-6 K -1 |

Isi atụmatụ

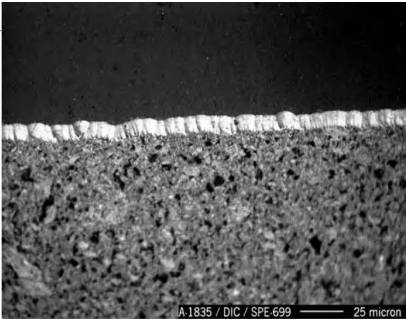

N'elu bụ ok na enweghị pores.

Ịdị ọcha dị elu, mkpokọta adịghị ọcha <20ppm, ezigbo ikuku.

High okpomọkụ eguzogide, ike na-abawanye na-amụba ojiji okpomọkụ, na-eru kasị elu uru na 2750 ℃, sublimation na 3600 ℃.

Module ngbanwe dị ala, conductivity thermal dị elu, ọnụọgụ mgbasawanye ọkụ dị ala, yana nguzogide ujo dị mma.

Nkwụsi ike kemịkalụ dị mma, na-eguzogide acid, alkali, nnu, na reagents organic, ọ nweghịkwa mmetụta na ọla gbazere, slag, na mgbasa ozi ndị ọzọ na-emebi emebi. Ọ dịghị oxidize nke ukwuu na ikuku n'okpuru 400 C, na oxidation ọnụego budata na-abawanye na 800 ℃.

Na-ahapụghị gas ọ bụla na oke okpomọkụ, ọ nwere ike idowe oghere nke 10-7mmHg na gburugburu 1800C.

Ngwa ngwaahịa

Na-agbaze crucible maka evaporation na semiconductor ụlọ ọrụ.

Ọnụ ụzọ tube eletrọnịkị dị elu.

Ahịhịa na-akpọtụrụ voltaji regulator.

Graphite monochromator maka X-ray na neutron.

Ụdị dị iche iche nke graphite substrates na atomiki absorption tube mkpuchi.

Mmetụta mkpuchi carbon pyrolytic n'okpuru microscope 500X, na-emebibeghị na nke mechiri emechi.

Mkpuchi TaC bụ ọgbọ ọhụrụ ihe na-eguzogide okpomọkụ dị elu, yana nkwụsi ike dị elu dị elu karịa SiC. Dị ka a corrosion na-eguzogide mkpuchi, mgbochi ọxịdashọn mkpuchi na-eyi na-eguzogide mkpuchi, nwere ike ji mee ihe na gburugburu ebe obibi n'elu 2000C, ọtụtụ ebe na-eji aerospace ultra-elu okpomọkụ na-ekpo ọkụ akụkụ ọgwụgwụ, ọgbọ nke atọ semiconductor otu kristal ibu ubi.

| Njirimara anụ ahụ nke mkpuchi TaC | |

| Njupụta | 14.3 (g/cm3) |

| Mgbapụta pụrụ iche | 0.3 |

| Ọnụọgụ mgbasawanye okpomọkụ | 6.3 10/K |

| Isi ike (HK) | 2000 HK |

| Nguzogide | 1 x 10-5 Ohm * cm |

| Nkwụsi ike okpomọkụ | <2500 ℃ |

| Mgbanwe nha eserese | -10 ~ -20 nkeji |

| mkpuchi mkpuchi | ≥220um ahụkarị uru (35um± 10um) |

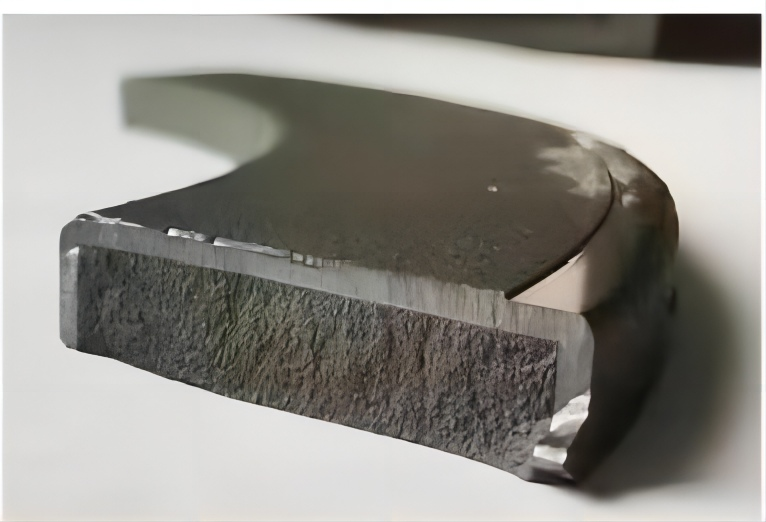

A na-amata akụkụ siri ike CVD SILICON CARBIDE dị ka nhọrọ bụ isi maka mgbanaka RTP/EPI na bases na plasma etch cavity akụkụ nke na-arụ ọrụ na sistemụ dị elu chọrọ okpomọkụ ọrụ (> 1500 Celsius C), ihe achọrọ maka ịdị ọcha dị elu (> 99.9995%). na arụmọrụ dị mma karịsịa mgbe kemịkalụ na-eguzogide tol dị elu karịsịa. Ihe ndị a enweghị akụkụ nke abụọ na nsọtụ ọka, ya mere akụkụ ha na-emepụta ihe dị nta karịa ihe ndị ọzọ. Na mgbakwunye, enwere ike ihicha ihe ndị a site na iji HF / HCI na-ekpo ọkụ na-enwe obere mmebi, na-akpata obere irighiri ihe na ndụ ọrụ dị ogologo.