Ụgbọ mmiri SiC Wafer

Silicon carbide wafer ụgbọ mmiribụ ngwaọrụ na-ebu ibu maka wafers, nke a na-ejikarị na usoro mgbasa ozi nke anyanwụ na semiconductor. O nwere njirimara ndị dị ka ihe mgbochi iyi, nkwụsị nke corrosion, nkwụsị mmetụta okpomọkụ dị elu, nkwụsị nke bombu plasma, ikike ịdị elu nke okpomọkụ, okpomọkụ dị elu, ikpo ọkụ dị elu, na iji ogologo oge na-adịghị mfe ịgbagọ na nrụrụ. Ụlọ ọrụ anyị na-eji silicon carbide ihe dị ọcha dị elu iji hụ na ndụ ọrụ ma na-enye atụmatụ ahaziri iche, gụnyere. dị iche iche vetikal na kehoraizinụgbọ mmiri wafer.

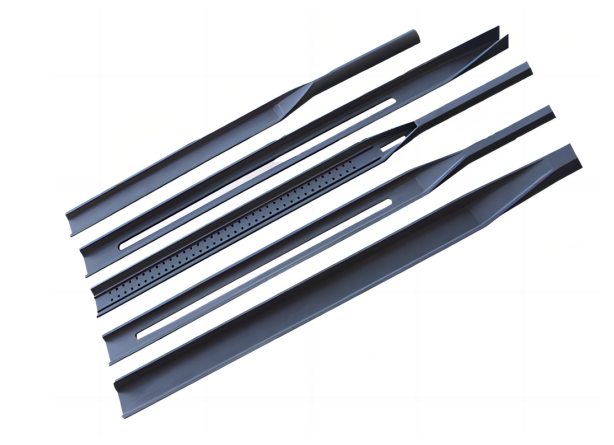

SiC Paddle

Nkesilicon carbide cantilever paddleA na-ejikarị na mkpuchi (mgbasa) nke silicon wafers, nke na-arụ ọrụ dị oke mkpa na ntinye na njem nke silicon wafers na elu okpomọkụ. Ọ bụ isi akụrụngwa nkesemiconductor waferSistemụ nbudata ma nwee njirimara isi ndị a:

1. Ọ naghị eme ka ọ dị elu na gburugburu ebe okpomọkụ dị elu ma nwee nnukwu ibu ibu na wafers;

2. Ọ na-eguzogide oke oyi na okpomọkụ ngwa ngwa, ma nwee ogologo ndụ ọrụ;

3. Ọnụ ọgụgụ mgbasawanye nke thermal dị ntakịrị, na-agbatị usoro nlekọta na nhichapụ nke ukwuu, ma na-ebelata mmetọ nke ukwuu.

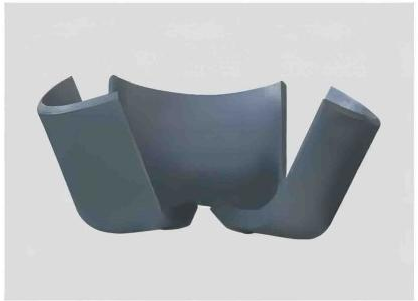

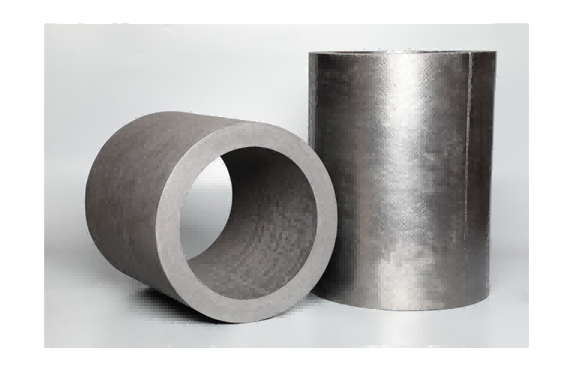

SiC Furnace Tube

Silicon carbide usoro tube, Ejiri SiC dị elu dị ọcha na-enweghị ihe ndị na-adịghị mma, adịghị emerụ wafer, ọ dịkwa mma maka usoro dịka semiconductor na mgbasa ozi fotovoltaic, usoro annealing na oxidation.

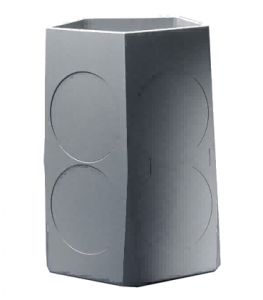

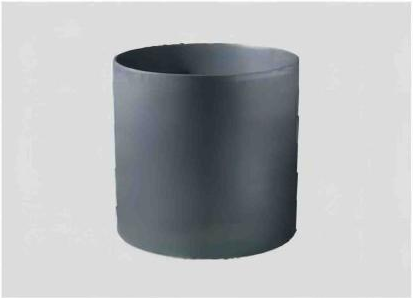

SiC Robot Arm

SiC robot ogwe aka, nke a makwaara dị ka onye na-ebufe njedebe wafer, bụ ogwe aka robotic eji ebufe wafers semiconductor ma na-ejikarị ya na semiconductor, optoelectronic, na ike anyanwụ. Iji silicon carbide dị ọcha, nke nwere isi ike dị elu, na-eyi nguzogide, nguzogide seismic, iji ogologo oge na-enweghị nrụrụ, ogologo ndụ ọrụ, wdg, nwere ike ịnye ọrụ ahaziri iche.

Graphite maka uto kristal

Ọta okpomọkụ graphite

Graphite electrode tube

Ihe ngbanwe eserese

graphite mma

Usoro niile a na-eji maka crvstals semiconductor na-eto eto na-arụ ọrụ na gburugburu okpomọkụ dị elu na nke na-emebi emebi. Mpaghara na-ekpo ọkụ nke ọkụ na-eto kristal na-ejikarị ịdị ọcha na-eguzogide okpomọkụ na corrosion na-eguzogide. graphite components, dị ka graphite heaters, crucibles, cylinders, deflector, chucks, tubes, yiri mgbaaka, njide, mkpụrụ, wdg anyị emechara ngwaahịa nwere ike nweta ihe ash ọdịnaya na-erughị 5ppm.

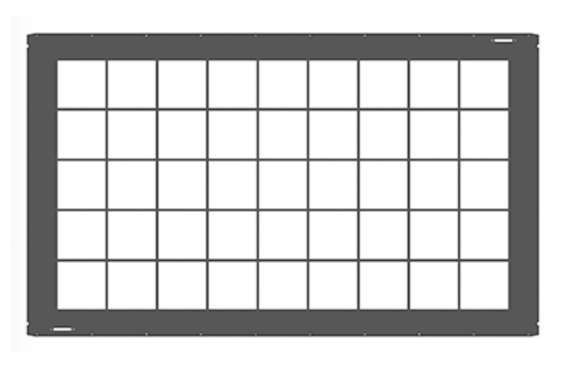

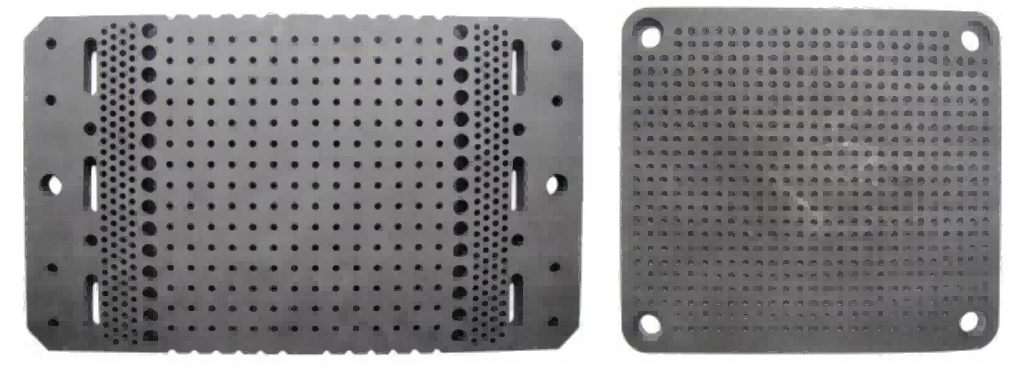

Eserese maka Semidonductor Epitaxy

Akụkụ MOCVD Graphite

Semiconductor Graphite Fixture

Usoro epitaxial na-ezo aka na uto nke otu ihe kristal na otu mkpụrụ kristal nwere otu nhazi lattice dị ka mkpụrụ. Ọ na-achọ ọtụtụ akụkụ graphite dị ọcha dị elu yana ntọala graphite nwere mkpuchi SIC. Grafite dị elu nke a na-eji maka epitaxy semiconductor nwere ọtụtụ ngwa, nke nwere ike dakọtara na ngwá ọrụ a na-ejikarị eme ihe na ụlọ ọrụ, N'otu oge ahụ, ọ nwere oke elu. ịdị ọcha, mkpuchi otu, ndụ ọrụ magburu onwe ya, yana oke nguzogide kemịkalụ na nkwụsi ike ọkụ.

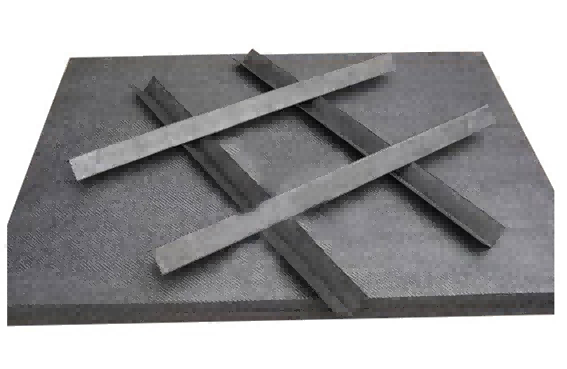

Ihe mkpuchi mkpuchi na ihe ndị ọzọ

Thermal mkpuchi ihe eji na semiconductor mmepụta bụ graphite ike chere, nro chere, graphite foil, carbon composite ihe, wdg anyị akụrụngwa na-dị ka graphite ihe, nke nwere ike bee dị ka nkọwapụta nke ndị ahịa, na nwekwara ike na-ere dị ka a. dum. A na-ejikarị ihe mejupụtara carbon carbon dị ka onye na-ebu maka usoro mmepụta cell monocrystal anyanwụ na polysilicon.