Uru

Nguzogide oxidation dị elu

Nguzogide corrosion mara mma

Ezigbo nguzogide abrasion

Ọnụ ọgụgụ dị elu nke conductivity okpomọkụ

Mmanya onwe onye, obere njupụta

Isi ike dị elu

Nhazi ahaziri.

Ngwa

- Ubi na-eguzogide ọgwụ: ịhịa aka n'ahụ, efere, mmiri na-agbapụta ájá, mkpuchi cyclone, gbọmgbọm egweri, wdg ...

-Akụkụ dị elu: siC Slab, Quenching Furnace Tube, Radiant Tube, Crucible, Heat Element, Roller, Beam, Heat Exchanger, Cold Air Pipe, Burner Nozzle, Thermocouple Protection Tube, SiC ụgbọ mmiri, Kiln ụgbọ ala Structure, Setter, wdg.

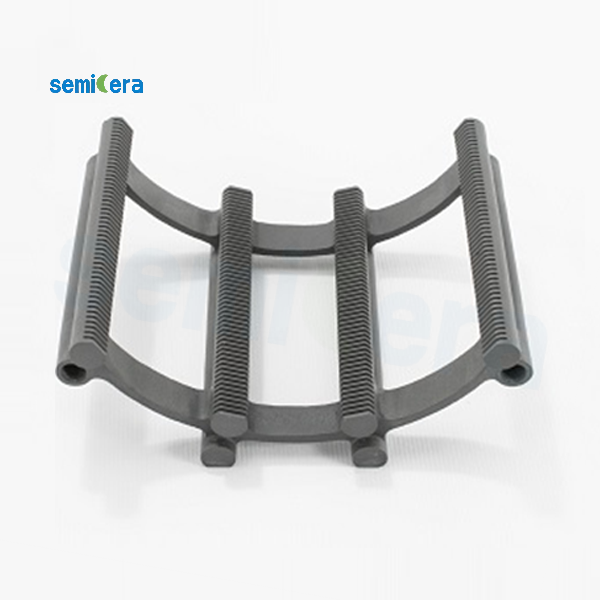

-Silicon Carbide Semiconductor: SiC wafer ụgbọ mmiri, sic chuck, sic paddle, sic cassette, sic diffusion tube, wafer ndụdụ, mmiri ara ehi, ụzọ ụzọ, wdg.

-Silicon Carbide Seal Field: ụdị mgbanaka akara niile, ibu, ahịhịa, wdg.

-Ubi fotovoltaic: Cantilever Paddle, Grinding Barrel, Silicon Carbide Roller, wdg.

- Ubi batrị lithium

Njirimara anụ ahụ SiC

| Ngwongwo | Uru | Usoro |

| Njupụta | 3.21 g/cc | Sink-ese n'elu na akụkụ |

| Okpomọkụ akọwapụtara | 0.66 J/g °K | Igwe ọkụ laser gbara agba |

| Ike mgbanwe | 450 MPa 560 MPa | Ehulata isi 4, isi isi RT4, 1300° |

| Mgbaji siri ike | 2.94 MPa m1/2 | Microindentation |

| Isi ike | 2800 | Vicker, ibu 500 g |

| Modulus nke na-agbanwe agbanwe | 450 GPa430 | 4 pt gbagọọ, RT4 pt gbagọọ, 1300 Celsius |

| Nha ọka | 2-10 µm | SEM |

Njirimara Thermal nke SiC

| Nrụpụta okpomọkụ | 250 W/m °K | Laser flash usoro, RT |

| Mgbasawanye okpomọkụ (CTE) | 4.5 x 10-6 °K | Okpomọkụ ụlọ ruo 950 Celsius C, silica dilatometer |

Nka nka

| Ihe | Nkeji | Data | ||||

| RBSiC (SiSiC) | NBSiC | SSiC | RSiC | OsiC | ||

| SiC ọdịnaya | % | 85 | 75 | 99 | 99.9 | ≥99 |

| Ọdịnaya silicon efu | % | 15 | 0 | 0 | 0 | 0 |

| Oke ọrụ okpomọkụ | ℃ | 1380 | 1450 | 1650 | 1620 | 1400 |

| Njupụta | g/cm3 | 3.02 | 2.75-2.85 | 3.08-3.16 | 2.65-2.75 | 2.75-2.85 |

| Mepee porosity | % | 0 | 13-15 | 0 | 15-18 | 7-8 |

| Ike na-ehulata 20 ℃ | Nna | 250 | 160 | 380 | 100 | / |

| Ehulata ike 1200 ℃ | Nna | 280 | 180 | 400 | 120 | / |

| Modul nke elasticity 20 ℃ | Gpa | 330 | 580 | 420 | 240 | / |

| Modul nke elasticity 1200 ℃ | Gpa | 300 | / | / | 200 | / |

| Thermal conductivity 1200 ℃ | W/mK | 45 | 19.6 | 100-120 | 36.6 | / |

| Ọnụọgụ nke mgbasawanye thermal | K-1X10-6 | 4.5 | 4.7 | 4.1 | 4.69 | / |

| HV | Kg/mm2 | 2115 | / | 2800 | / | / |

Ihe mkpuchi silicon carbide nke CVD dị n'elu elu nke ngwaahịa seramiiki silicon carbide recrystallized nwere ike iru ịdị ọcha karịa 99.9999% iji gboo mkpa ndị ahịa na ụlọ ọrụ semiconductor.