Nzụlite nyocha

Ngwa mkpa nke silicon carbide (SiC): Dị ka nnukwu bandgap semiconductor ihe, silicon carbide adọtala anya nke ukwuu n'ihi na ya magburu onwe eletriki Njirimara (dị ka nnukwu bandgap, elu eletrọn saturation ọsọ na thermal conductivity). Ngwongwo ndị a na-eme ka a na-ejikarị ya eme ihe n'ichepụta ngwaọrụ dị elu, okpomọkụ na ike dị elu, karịsịa n'ọhịa nke ngwá electronic.

Mmetụta nke ntụpọ kristal: N'agbanyeghị uru ndị a nke SiC, ntụpọ dị na kristal na-anọgide na-abụ nnukwu nsogbu na-egbochi mmepe nke ngwaọrụ dị elu. Nrụrụ ndị a nwere ike ịkpata mmebi ngwaọrụ ma na-emetụta ntụkwasị obi ngwaọrụ.

Teknụzụ onyogho topological X-ray: Iji kwalite uto kristal ma ghọta mmetụta nke ntụpọ na arụmọrụ ngwaọrụ, ọ dị mkpa ịkọwapụta na nyochaa nhazi ntụpọ na kristal SiC. Onyonyo onyogho nke X-ray (karịsịa iji synchrotron radieshon radieshon) aghọwo usoro njirimara dị mkpa nke nwere ike ịmepụta ihe oyiyi dị elu nke nhazi ime nke kristal.

Echiche nyocha

Dabere na teknụzụ ịme anwansị ray tracing: Akụkọ ahụ tụrụ aro ka eji teknụzụ ịme simulation ray dabere na usoro ntụgharị ihu iji mee ka ọdịiche ntụpọ ahụ dị na foto topological X-ray n'ezie. Egosiputara usoro a ka ọ bụrụ ụzọ dị irè iji mụọ njirimara nke ntụpọ kristal na semiconductor dị iche iche.

Mmelite nke nkà na ụzụ simulation: Iji mee ka ọ dịkwuo mma ịmegharị nkwụsịtụ dị iche iche a na-ahụ na kristal 4H-SiC na 6H-SiC, ndị nchọpụta ahụ mere ka nkà na ụzụ simulation ray na-eme ka ọ dịkwuo mma ma tinye mmetụta nke ntụrụndụ elu na ntinye fotoelectric.

Ọdịnaya nyocha

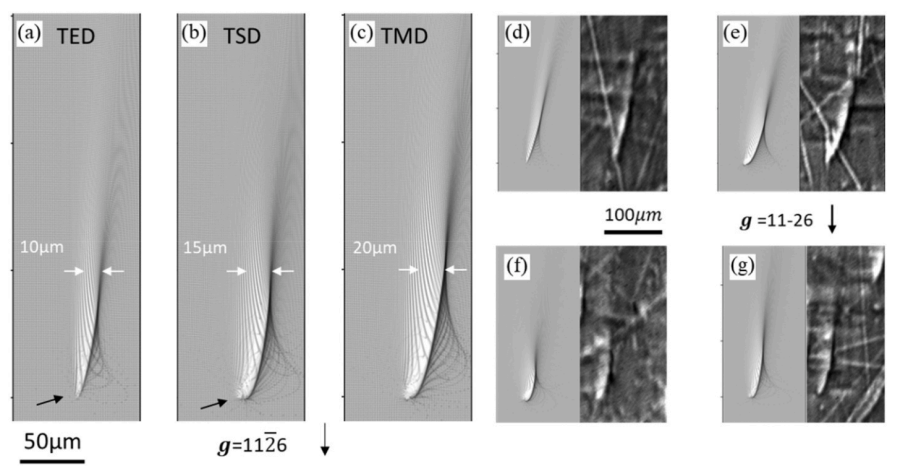

Nyocha ụdị nkwụsịtụ: Isiokwu ahụ na-enyocha nhazi nke njirimara nke ụdị nkwụsịtụ dị iche iche (dịka nkwụsịtụ screw, dislocations edges, mix dislocations, basal flight dislocations and Frank-type dislocations) na ụdị dị iche iche nke SiC (gụnyere 4H na 6H) site na iji ray tracing. teknụzụ ịme anwansị.

Ngwa nke teknụzụ ịme anwansị: A na-amụ ngwa nke teknụzụ ịme anwansị ray tracing n'okpuru ọnọdụ ọkụ dị iche iche dị ka topology beam na-adịghị ike na topology nke ụgbọ elu, yana otu esi achọpụta omimi ntinye dị mma nke dislocations site na teknụzụ ịme anwansị.

Nchikota nke nnwale na simulations: Site n'ịtụle ihe onyonyo topological nke X-ray enwetara na ihe onyonyo a na-eme ka ọ dị, a na-achọpụta izi ezi nke teknụzụ ịme anwansị na-achọpụta ụdị dislocation, vector Burgers na nkesa oghere nke dislocations na crystal.

Nkwubi okwu nyocha

Ịdị irè nke nkà na ụzụ simulation: Ọmụmụ ihe na-egosi na ray tracing technology simulation bụ ụzọ dị mfe, nke na-adịghị emebi emebi na enweghị mgbagwoju anya iji kpughee njirimara nke ụdị dislocations dị iche iche na SiC ma nwee ike ịkọwapụta nke ọma na ntinye ntinye dị irè nke nkwụsịtụ.

Ntụle nhazi nhazi 3D: Site na teknụzụ ịme anwansị, 3D nhazi nhazi nhazi na nha njupụta nwere ike ịrụ ọrụ, nke dị oké mkpa maka ịghọta omume na evolushọn nke dislocations n'oge uto kristal.

Ngwa n'ọdịniihu: A na-atụ anya na teknụzụ ịme anwansị Ray tracing ga-etinyekwu n'ọrụ na topology ike dị elu yana topology X-ray dabere na ụlọ nyocha. Na mgbakwunye, teknụzụ a nwekwara ike ịgbatị na ịme anwansị nke njirimara ntụpọ nke ụdị polytypes ndị ọzọ (dịka 15R-SiC) ma ọ bụ ihe ndị ọzọ semiconductor.

Nchịkọta ihe osise

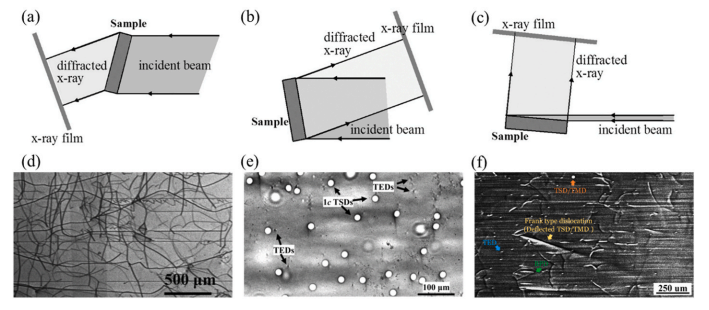

Fig. 1: Eserese eserese nke synchrotron radieshon X-ray topological imaging ntọlite, gụnyere nnyefe (Laue) geometry, ntụgharị ntụgharị (Bragg) geometry, na geometry ịta nri. A na-ejikarị geometry ndị a edekọ onyonyo topological X-ray.

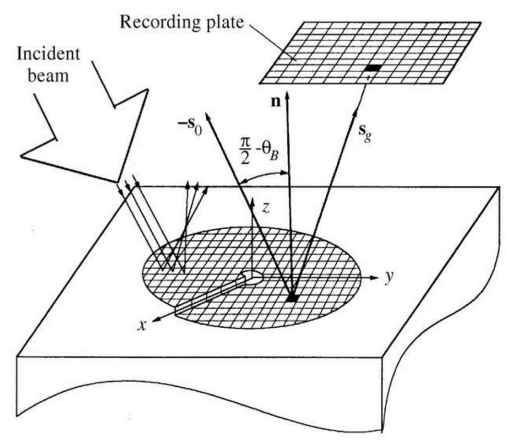

Fig. 2: Eserese eserese nke X-ray diffraction nke mpaghara gbagọrọ agbagọ n'akụkụ mgbakasị ahụ. Ọnụọgụ a na-akọwa mmekọrịta dị n'etiti oghere ihe ahụ merenụ (s0) na ebe dịpụrụ adịpụ (sg) na ụgbọ elu diffraction mpaghara nkịtị (n) na mpaghara Bragg angle (θB).

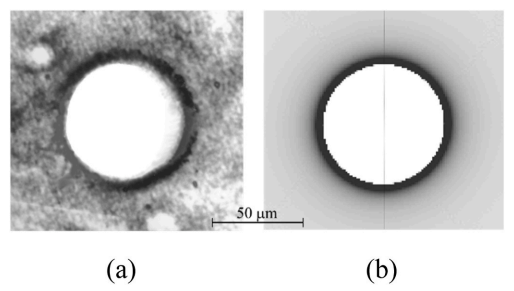

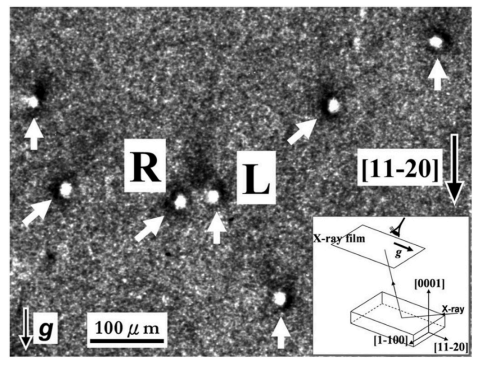

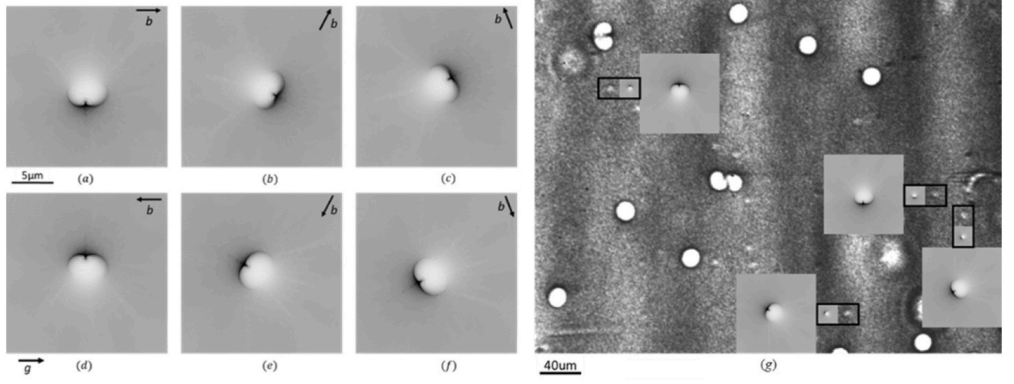

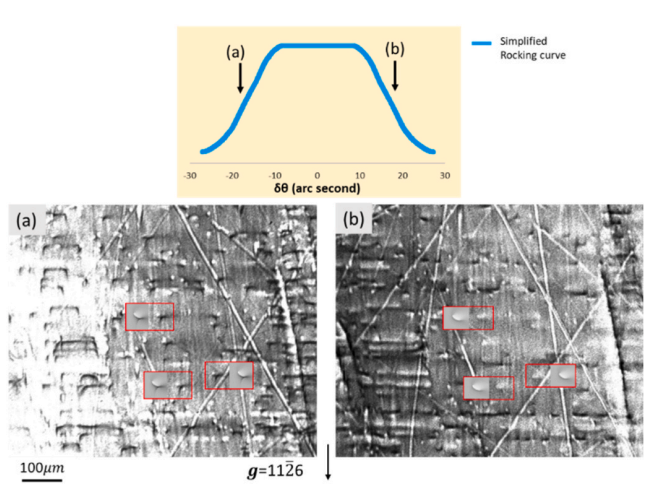

Fig. 3: Ntụgharị azụ nke X-ray topography onyogho nke micropipes (MPs) na 6H-SiC wafer na ọdịiche nke nkwụsịtụ nke simulated screw dislocation (b = 6c) n'okpuru otu ọnọdụ dị iche iche.

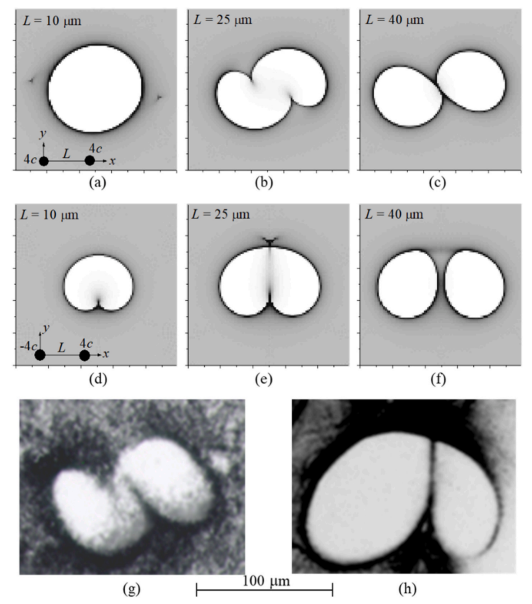

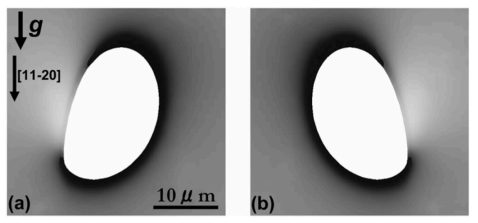

Fig. 4: Micropipe abụọ n'ime ihe onyonyo ntụgharị azụ azụ nke wafer 6H–SiC. A na-egosi onyonyo nke otu ndị omeiwu nwere oghere dị iche iche na ndị omeiwu n'akụkụ dị iche iche site na simulations tracing ray.

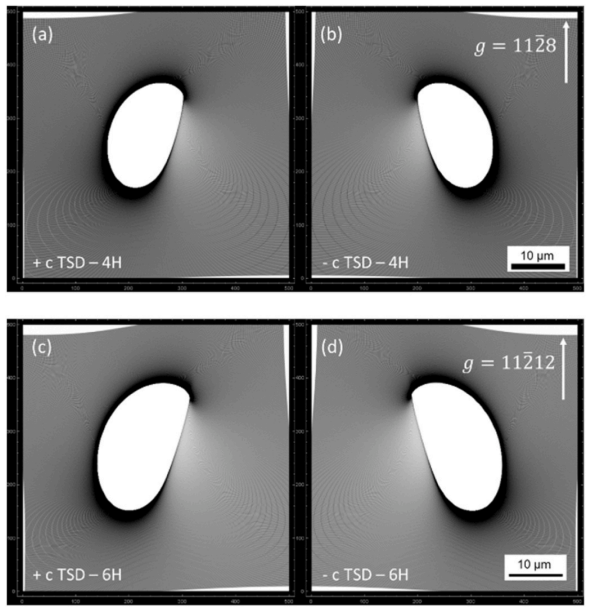

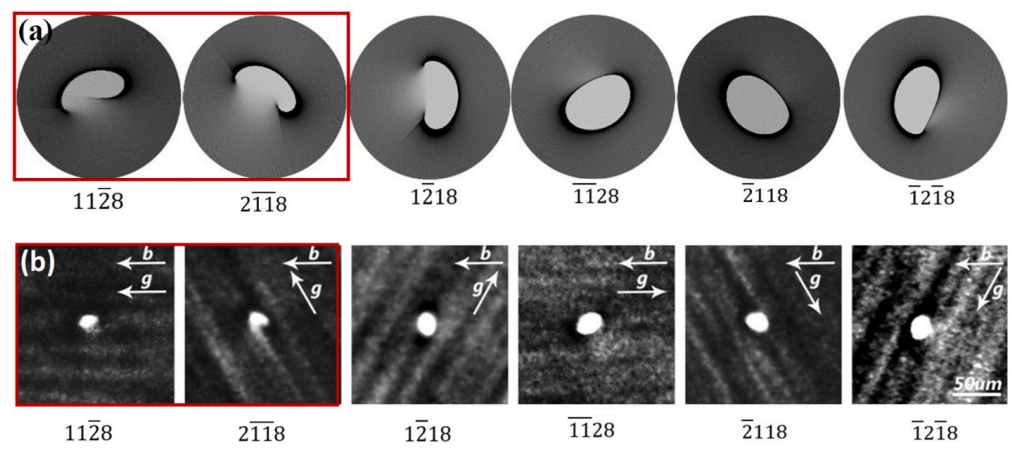

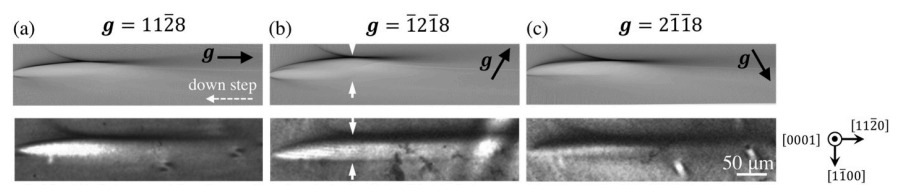

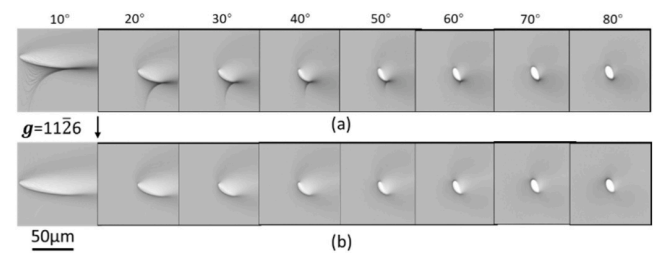

Fig. 5: ihe onyonyo onyonyo onyonyo X-ray na-ata nri nke mechiri emechi screw dislocations (TSDs) na wafer 4H–SiC ka egosiri. Onyonyo a na-egosi ọdịiche ihu agbalitere.

Fig. 6: A na-egosi ihe ngosi ngosi ihe ngosi ihe ngosi nke ihe ngosi X-ray nke 1c TSD aka ekpe na aka nri na wafer 4H–SiC.

Fig. 7: E gosipụtara ihe ngosi Ray tracing simulations nke TSD na 4H-SiC na 6H-SiC, na-egosi nkwụsịtụ na vectors Burgers dị iche iche na ụdị polytypes.

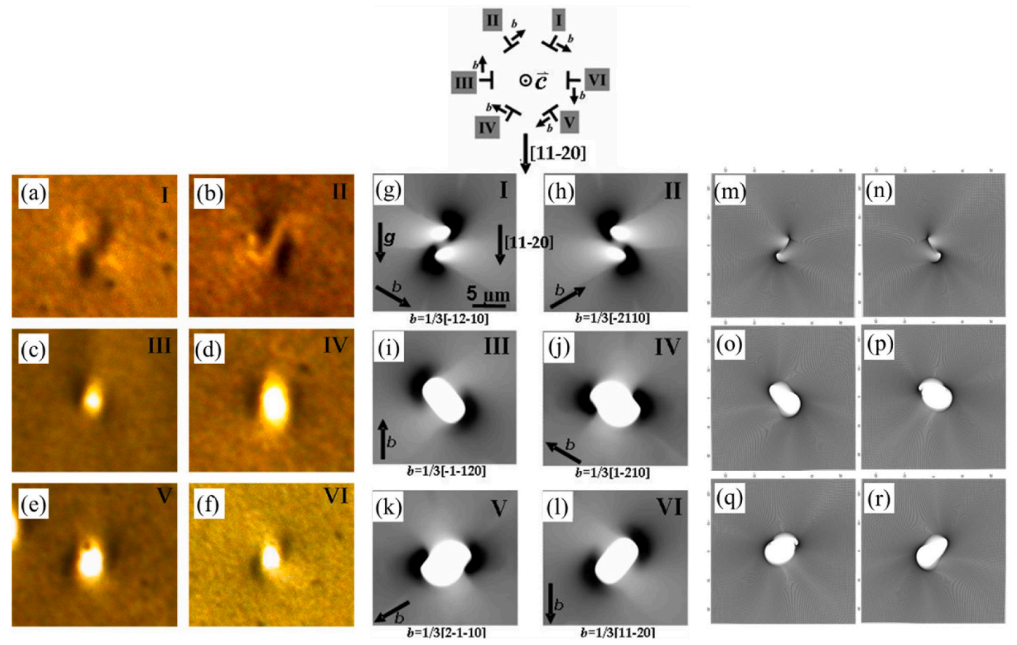

Fig. 8: Na-egosiputa ihe omume ịta nri X-ray topological onyo dị iche iche nke threading onu dislocations (TEDs) na 4H-SiC wafers, na TED topological oyiyi simulated site na iji usoro tracing usoro.

Fig. 9: Na-egosiputa ihe oyiyi topological nke X-ray na-atụgharị azụ nke ụdị TED dị iche iche na 4H-SiC wafers, na ihe dị iche iche TED simulated.

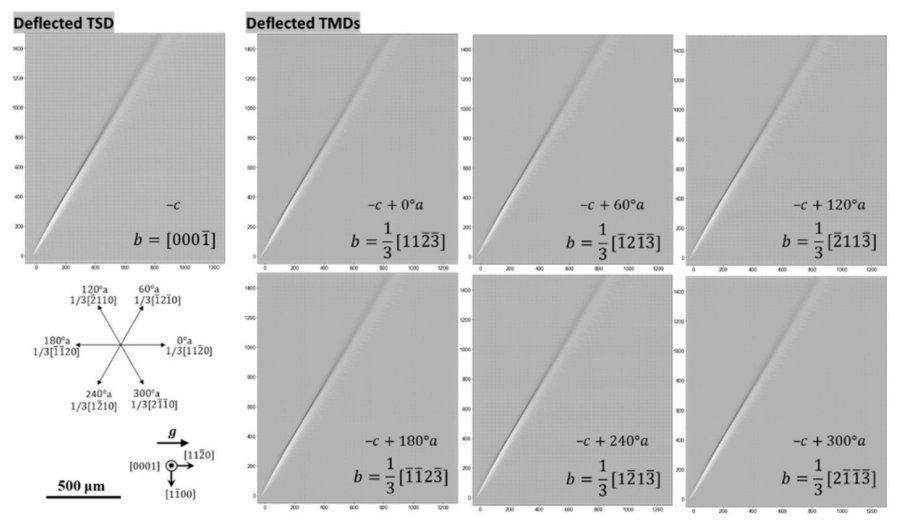

Fig. 10: Na-egosiputa ihe onyonyo simulation nke ray na-akpachapụ anya nke mgbagwoju anya (TMDs) yana vector Burgers kpọmkwem, yana onyonyo topological nnwale.

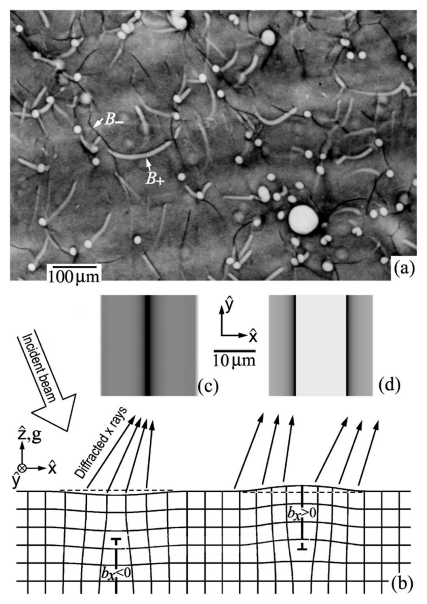

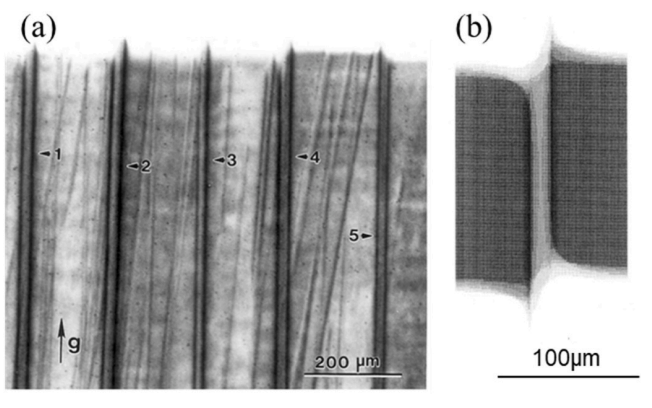

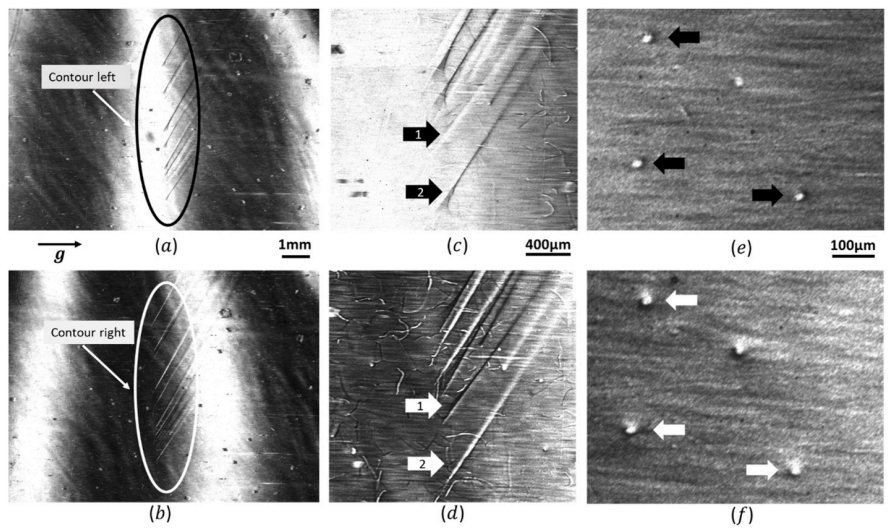

Fig. 11: Na-egosiputa ihe oyiyi topological na-atụgharị azụ nke nkwụsị ụgbọ elu basal (BPDs) na 4H-SiC wafers, na schematic diagram nke simulated onu dislocation iche.

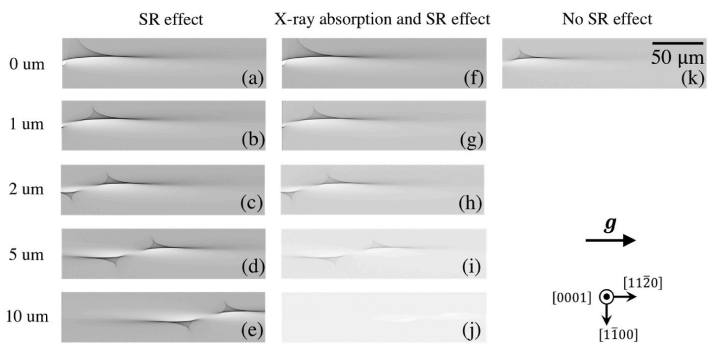

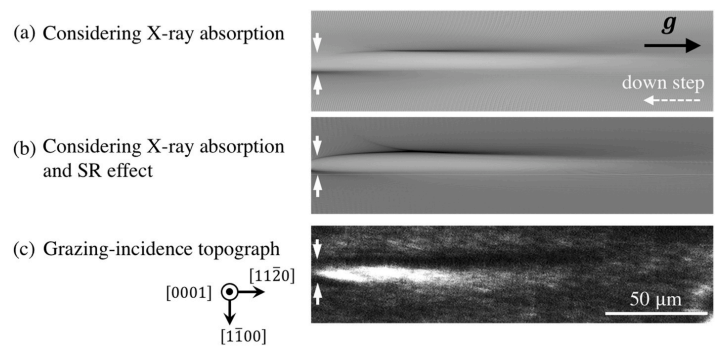

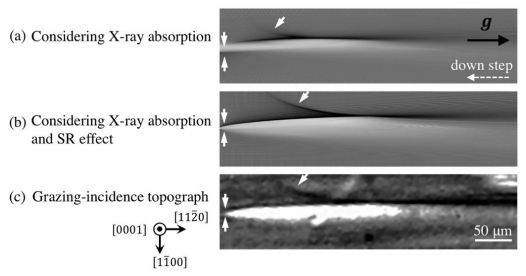

Foto 12: Na-egosiputa ray na-achọpụta ihe ngosi simulation nke BPDs helical aka nri na omimi dị iche iche na-atụle ntụrụndụ elu na mmetụta absorption fotoelectric.

Foto 13: Na-egosiputa ihe onyonyo simulation nke ray na-ahụ maka mgbanaka BPD nwere aka nri na omimi dị iche iche, yana ihe onyonyo onyonyo topological X-ray na-ata nri.

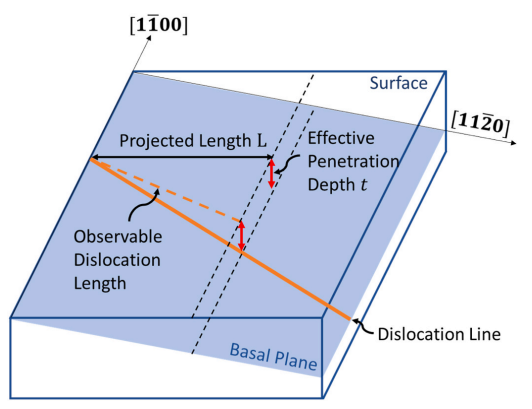

Foto 14: Na-egosiputa ihe osise nke basal ụgbọ elu dislocations na ntụziaka ọ bụla na 4H-SiC wafers, na otu esi achọpụta omimi ntinye site na ịlele ogologo ntule.

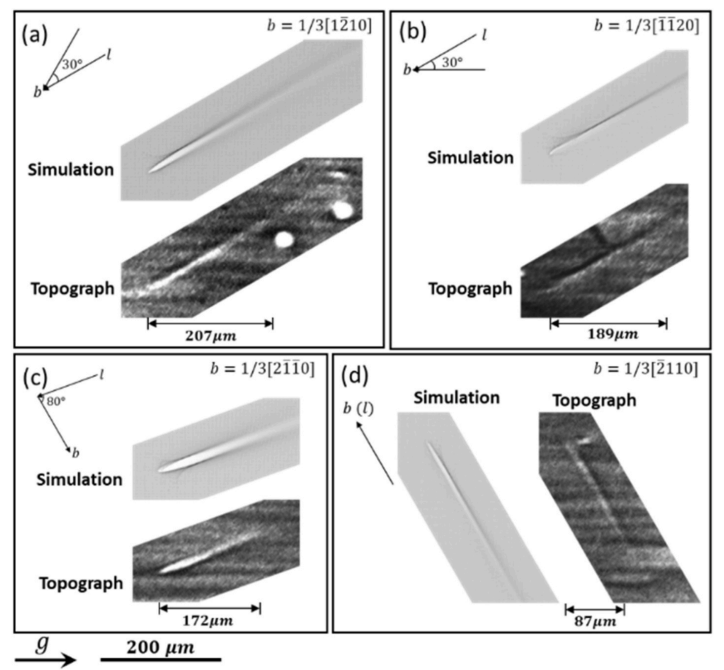

Fig 15: Ọdịiche nke BPD nwere vectors Burgers dị iche iche na ntụzịaka ahịrị n'ihe onyonyo topological X-ray na-ata nri, yana nsonaazụ nyocha ray kwekọrọ.

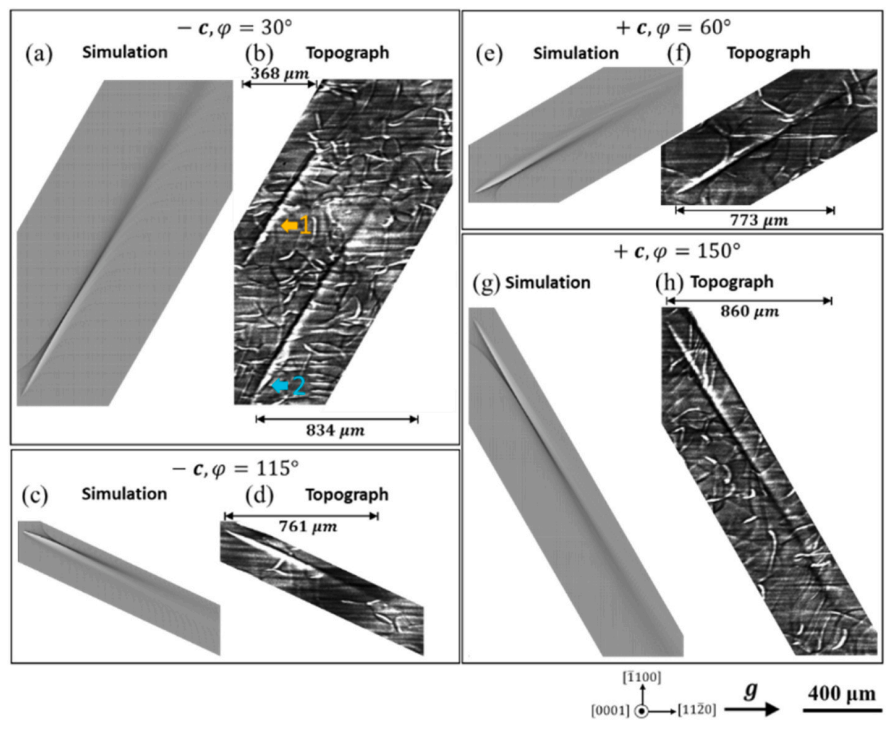

Foto 16: Ihe onyonyo simulation ray nke TSD aka nri tụgharịrị na wafer 4H-SiC, yana ihe onyonyo onyonyo topological X-ray na-ata nri ka egosiri.

Fig. 17: E gosipụtara simulation ray tracing na onyonyo nnwale nke TSD atụgharị na 8° defet 4H-SiC wafer.

Foto 18: Ihe onyonyo simulation nke ray nke TSD na TMD agbagoro nwere vectors Burgers dị iche iche mana otu ahịrị ahụ ka egosiri.

Nkeji 19: Ihe onyonyo simulation nke ray nke ụdị dislocations nke Frank, yana ihe onyonyo onyonyo topological X-ray dabara adaba.

Foto 20: Ihe onyonyo topological X-ray a na-ebunye na-acha ọcha nke micropipe dị na wafer 6H-SiC, yana onyonyo simulation ray na-egosi.

Fig. 21: Ihe omume ịta nri monochromatic X-ray topological image nke axially bee sample nke 6H-SiC, na ray tracing oyiyi simulation nke BPDs ka egosiri.

Fig. 22: na-egosi ray tracing simulation onyoonyo nke BPDs na 6H-SiC axially bee samples n'akụkụ dị iche iche merenụ.

Foto 23: na-egosi ihe onyonyo simulation ray nke TED, TSD na TMD na 6H-SiC axially bee samples n'okpuru geometry ihe oriri.

Foto 24: na-egosi ihe onyonyo topological X-ray nke TSD ndị na-atụgharị n'akụkụ dị iche iche nke ahịrị isoclinic na wafer 4H-SiC, yana ihe oyiyi simulation ray kwekọrọ.

Edemede a bụ naanị maka ịkekọrịta agụmakwụkwọ. Ọ bụrụ na enwere mmebi iwu, biko kpọtụrụ anyị ka ihichapụ ya.

Oge nzipu: Jun-18-2024