N'ime usoro mmepụta nke semiconductor,etchingnkà na ụzụ bụ usoro dị oke egwu nke a na-eji wepụ kpọmkwem ihe ndị a na-achọghị na mkpụrụ iji mepụta usoro sekit dị mgbagwoju anya. Edemede a ga-ewebata teknụzụ etching abụọ bụ isi n'ụzọ zuru ezu - capacitively coupled plasma etching (CCP) na inductively jikọtara plasma etching.ICP), ma nyochaa ngwa ha na itching ihe dị iche iche.

Plasma etching capacitively jikọtara ọnụ (CCP)

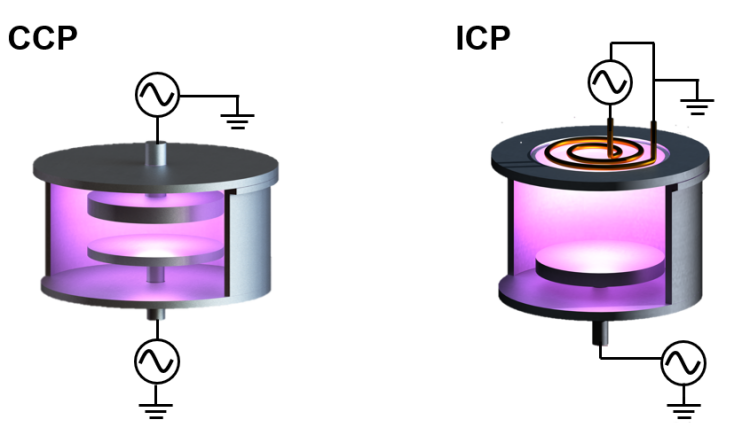

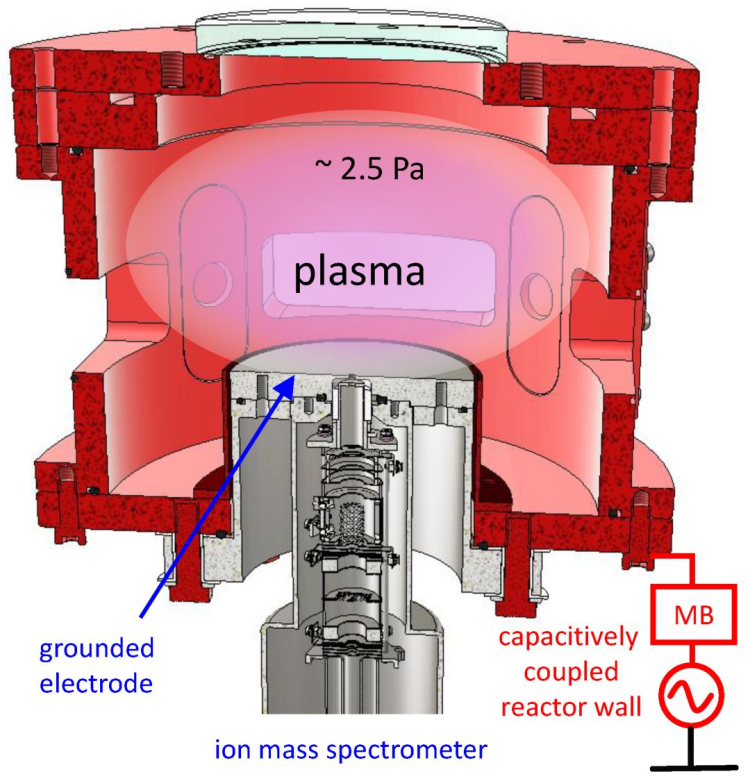

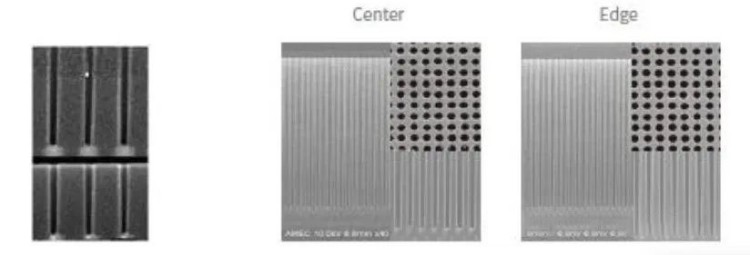

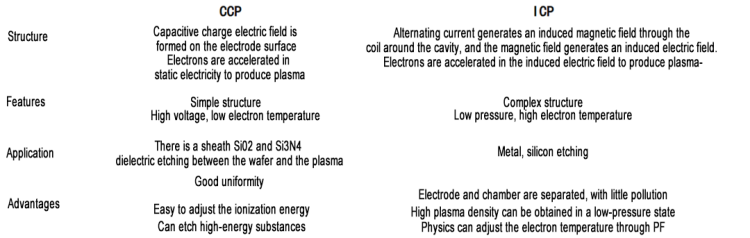

A na-enweta capacitively jikọtara plasma etching (CCP) site n'itinye voltaji RF na electrodes abụọ yiri ya site na matches na DC igbochi capacitor. Eletrọd abụọ ahụ na plasma ọnụ na-etolite otu capacitor. N'ime usoro a, voltaji RF na-etolite n'ọbọ capacitive n'akụkụ electrode, na ókè nke n'ọbọ na-agbanwe na ngwa ngwa oscillation nke voltaji. Mgbe eletrọnị rutere n'ọbọ a na-agbanwe ngwa ngwa, a na-egosipụta ha ma nweta ume, nke na-akpalite dissociation ma ọ bụ ionization nke mkpụrụ ndụ gas na-emepụta plasma. A na-etinyekarị CCP etching na ihe ndị nwere ike njikọ kemịkalụ dị elu, dị ka dielectrics, mana n'ihi ọnụego etching ya dị ala, ọ dabara maka ngwa chọrọ njikwa dị mma.

Plasma etching (ICP) jikọtara ya na inductively

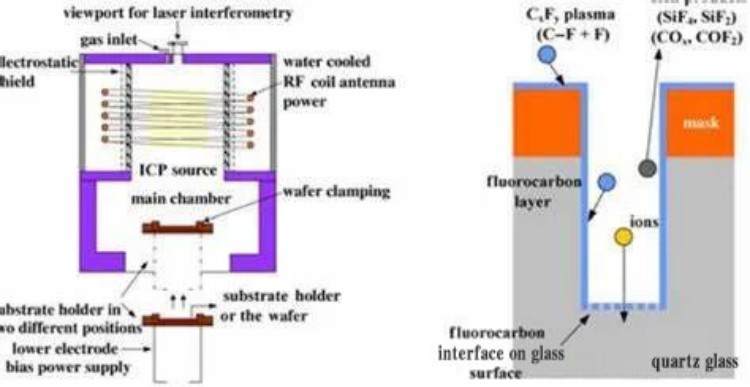

Plasma jikọtara ya na inductivelyetching(ICP) gbadoro ụkwụ n'ụkpụrụ ahụ bụ na ihe ọzọ na-agbanwe agbanwe na-agafe n'igwe mmiri iji mepụta oghere ndọta. N'okpuru ọrụ nke oghere magnetik a, ndị electrons na ụlọ mmeghachi omume na-emewanye ngwa ngwa ma na-aga n'ihu na-agba ọsọ na ọkụ eletrik na-ebute, na-emecha na-adaba na mmeghachi omume gas ụmụ irighiri ihe, na-eme ka ụmụ irighiri ihe kewapụ ma ọ bụ ionize ma mepụta plasma. Usoro a nwere ike iwepụta ọnụ ọgụgụ ionization dị elu ma kwe ka njupụta plasma na ike bombu gbanwee n'onwe ya, nke na-eme ka ọ gbanwee.ICP na-akpụ akpụdabara nke ọma maka ihe etching nwere obere ike njikọ kemịkalụ, dị ka silicon na metal. Na mgbakwunye, teknụzụ ICP na-enyekwa otu n'otu na ọnụ ọgụgụ etching ka mma.

1. Metal etching

A na-ejikarị etching metal eme ihe maka nhazi njikọ njikọ na wiwi metal multi-layer. Ihe ndị ọ chọrọ gụnyere: ọnụ ọgụgụ dị elu nke etching, nhọrọ dị elu (karịa 4: 1 maka oyi akwa mkpuchi na karịa 20: 1 maka interlayer dielectric), akwa etching uniformity, ezigbo njikwa akụkụ dị oke egwu, enweghị mmebi plasma, obere mmetọ fọdụrụnụ, na enweghị corrosion na metal. Metal etching na-ejikarị ngwa etching plasma jikọtara ọnụ.

•Aluminom etching: Aluminom bụ ihe kacha mkpa waya ihe na n'etiti na azụ nkebi nke mgbawa n'ichepụta, na uru nke ala nguzogide, mfe ntinye na etching. Aluminom etching na-ejikarị plasma emepụtara site na chloride gas (dị ka Cl2). Aluminom na-emeghachi omume na chlorine iji mepụta aluminom chloride na-agbanwe agbanwe (AlCl3). Tụkwasị na nke a, enwere ike ịgbakwunye halides ndị ọzọ dị ka SiCl4, BCl3, BBr3, CCl4, CHF3, wdg iji wepụ ihe mkpuchi oxide n'elu aluminom iji hụ na etching nkịtị.

• Tungsten etching: Na multi-layer metal waya njikọ njikọ, tungsten bụ isi metal eji maka etiti ngalaba njikọ nke mgbawa. Enwere ike iji gas sitere na fluorine ma ọ bụ chlorine na-etch metal tungsten, mana gas ndị dabeere na fluorine nwere nhọrọ na-adịghị mma maka silicon oxide, ebe gas ndị dabeere na chlorine (dị ka CCl4) nwere nhọrọ ka mma. A na-etinyekarị nitrogen na gas mmeghachi omume iji nweta nnukwu etching gluu selectivity, na-agbakwunye oxygen iji belata ntinye carbon. Etching tungsten na gas dabeere chlorine nwere ike nweta anisotropic etching na elu selectivity. Gasị ndị a na-eji na-eme ka akọrọ akọrọ nke tungsten bụ SF6, Ar na O2, n'ime nke SF6 nwere ike imebi na plasma iji nye atom fluorine na tungsten maka mmeghachi omume kemịkalụ iji mepụta fluoride.

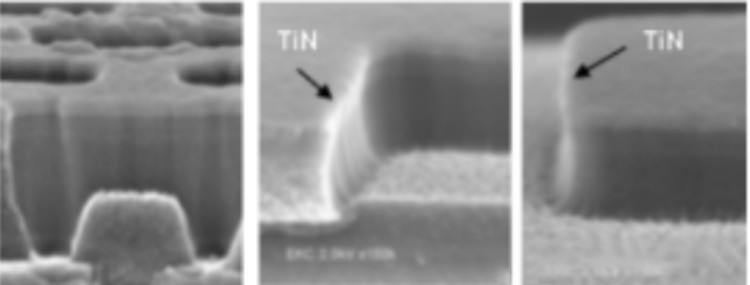

• Titanium nitride etching: Titanium nitride, dị ka ihe nkpuchi siri ike, na-edochi ihe mkpuchi silicon nitride ma ọ bụ oxide omenala na usoro damascene dual. A na-ejikarị titanium nitride etching eme ihe na usoro mmeghe nkpuchi siri ike, na ngwaahịa mmeghachi omume bụ isi bụ TiCl4. Nhọrọ dị n'etiti ihe nkpuchi ọdịnala na obere k dielectric oyi akwa adịghị elu, nke ga-eduga na ọdịdị nke profaịlụ arc n'elu ala dielectric oyi akwa na mgbasawanye nke obosara groove mgbe etching gasịrị. Oghere dị n'etiti ahịrị ọla edobere pere mpe, nke na-enwekarị ike ịwepu mmiri ma ọ bụ ndakpọ ozugbo.

2. Insulator etching

Ihe etching insulator na-abụkarị ihe dielectric dị ka silicon dioxide ma ọ bụ silicon nitride, nke a na-ejikarị eme oghere kọntaktị na oghere ọwa iji jikọọ ọkwa sekit dị iche iche. Dielectric etching na-ejikarị etcher dabere n'ụkpụrụ nke etching plasma na-ejikọta capacitively.

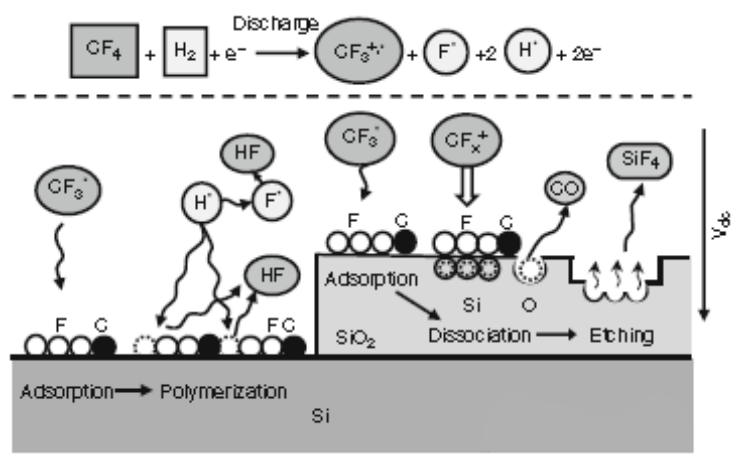

• Plasma etching nke ihe nkiri silicon dioxide: Silicon dioxide na-ejikarị eme ihe site na iji etching gas nwere fluorine, dị ka CF4, CHF3, C2F6, SF6 na C3F8. Carbon dị na etching gas nwere ike imeghachi omume na ikuku oxygen dị na oyi akwa oxide iji mepụta ngwaahịa CO na CO2, si otú ahụ wepụ oxygen na oyi akwa oxide. CF4 bụ gas etching nke a na-ejikarị. Mgbe CF4 na electrons nwere ike dị elu na-adaba, a na-emepụta ion dị iche iche, radicals, atom na free radicals. Fluorine free radicals nwere ike imeghachi omume na kemịkalụ na SiO2 na Si iji mepụta silicon tetrafluoride (SiF4) na-agbanwe agbanwe.

• Plasma etching nke silicon nitride film: Silicon nitride film nwere ike etched site na plasma etching na CF4 ma ọ bụ CF4 agwakọta gas (na O2, SF6 na NF3). Maka ihe nkiri Si3N4, mgbe a na-eji plasma CF4-O2 ma ọ bụ plasma gas ndị ọzọ nwere F atom maka etching, ọnụ ọgụgụ etching nke silicon nitride nwere ike iru 1200Å / min, na etching selectivity nwere ike ịdị elu dị ka 20: 1. Ngwaahịa bụ isi bụ silicon tetrafluoride (SiF4) na-agbanwe agbanwe nke dị mfe ịwepụta.

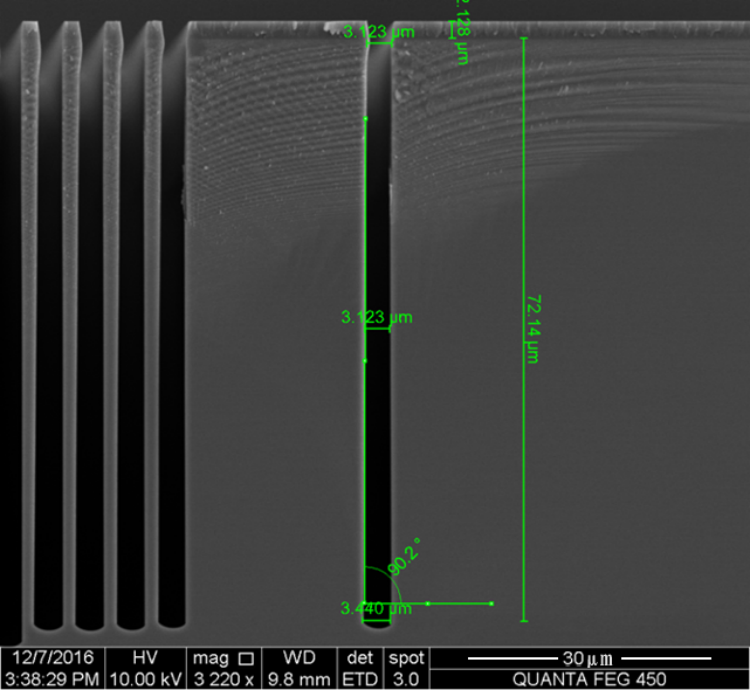

3. Single crystal silicon etching

A na-ejikarị etching silicon etching otu kristal na-emepụta ebe dịpụrụ adịpụ trenchi (STI). Usoro a na-agụnyekarị usoro ọganihu yana usoro isi etching. Usoro ihe ịga nke ọma na-eji SiF4 na NF gas wepụ ihe mkpuchi oxide n'elu otu silicon kristal site na bọmbụ ion siri ike na ọrụ kemịkal nke ihe fluorine; Isi etching na-eji hydrogen bromide (HBr) dị ka isi ihe na-emepụta ihe. Ihe radicals bromine nke HBr mebiri na gburugburu plasma na-emeghachi omume na silicon iji mepụta silicon tetrabromide (SiBr4), si otú ahụ wepụ silicon. Single crystal silicon etching na-ejikarị igwe etching plasma jikọtara ọnụ.

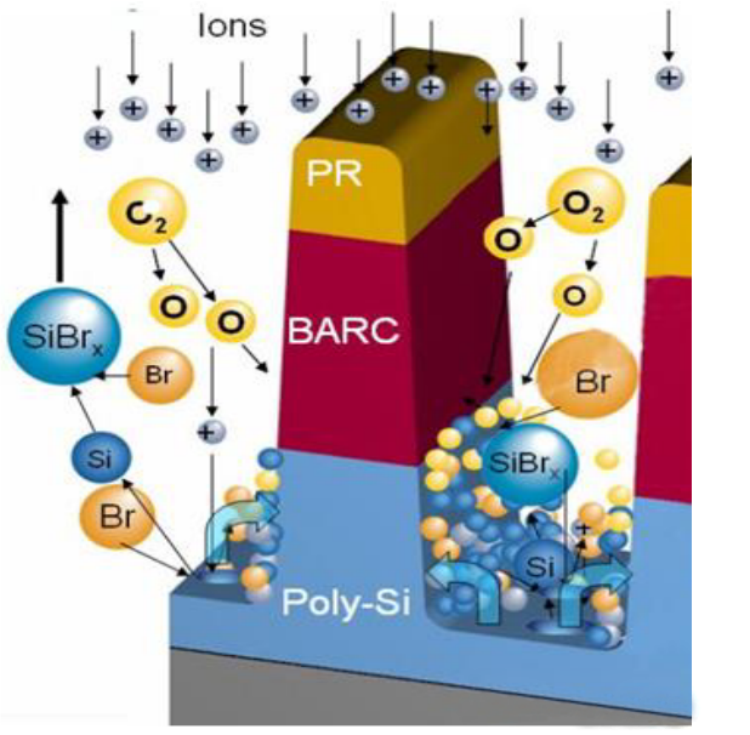

4. Polysilicon Etching

Polysilicon etching bụ otu n'ime isi usoro na-ekpebi oke ọnụ ụzọ ámá nke transistor, na nha ọnụ ụzọ ámá na-emetụta kpọmkwem arụmọrụ nke sekit agbakwunyere. Polysilicon etching chọrọ ezigbo nhọrọ nhọrọ. A na-ejikarị gas halogen dị ka chlorine (Cl2) eme ihe iji nweta etching anisotropic, ma nwee oke nhọrọ nhọrọ (ruo 10: 1). Gases sitere na bromine dị ka hydrogen bromide (HBr) nwere ike nweta oke nhọrọ nhọrọ (ruo 100: 1). Ngwakọta nke HBr nwere chlorine na oxygen nwere ike ịbawanye ọnụ ọgụgụ etching. A na-edobe ngwaahịa mmeghachi omume nke halogen gas na silicon n'akụkụ akụkụ iji rụọ ọrụ nchebe. Polysilicon etching na-ejikarị igwe etching plasma jikọtara ọnụ.

Ma ọ bụ plasma etching capacitively jikọtara ọnụ ma ọ bụ inductively jikọtara plasma etching, nke ọ bụla nwere uru pụrụ iche nke ya na njirimara teknụzụ. Ịhọrọ teknụzụ etching kwesịrị ekwesị nwere ike ọ bụghị naanị melite nrụpụta mmepụta, kamakwa hụ na mkpụrụ nke ngwaahịa ikpeazụ.

Oge nzipu: Nov-12-2024