N'ichepụta semiconductor, enwere usoro a na-akpọ "etching" n'oge nhazi nke mkpụrụ ma ọ bụ ihe nkiri dị mkpa nke a na-emepụta na mkpụrụ. Mmepe nke teknụzụ etching ekerewo òkè n'ịghọta amụma nke onye guzobere Intel Gordon Moore kwuru na 1965 na "njupụta njupụta nke transistors ga-abụ okpukpu abụọ n'ime afọ 1.5 ruo 2" (nke a na-akpọkarị "Moore's Law").

Etching abụghị usoro “mgbakwunye” dị ka ntinye ego ma ọ bụ njikọta, mana usoro “mwepu”. Na mgbakwunye, dị ka ụzọ dị iche iche scraping si dị, a na-ekewa ya ụzọ abụọ, ya bụ "mmiri etching" na "akọrọ etching". N'ikwu ya n'ụzọ dị mfe, nke mbụ bụ usoro ịgbaze na nke ikpeazụ bụ usoro egwu egwu.

N'isiokwu a, anyị ga-akọwa nkenke nke njirimara na ọdịiche nke nkà na ụzụ etching ọ bụla, mmiri etching na akọrọ etching, yana mpaghara ngwa maka nke ọ bụla kwesịrị ekwesị.

Nchịkọta nke usoro etching

Ekwuru na teknụzụ etching malitere na Europe na etiti narị afọ nke 15. N'oge ahụ, a na-awụsa acid n'ime efere ọla kọpa a kanyere iji mebie ọla kọpa ahụ na-adịghị ahụkebe, na-aghọ intaglio. Usoro ọgwụgwọ elu nke na-erigbu mmetụta nke corrosion bụ nke a maara nke ọma dị ka "etching."

Ebumnuche nke usoro etching na mmepụta semiconductor bụ ịkpụ mkpụrụ ma ọ bụ ihe nkiri na mkpụrụ dị ka eserese ahụ si dị. Site n'ịmeghachi usoro nkwado nke nhazi ihe nkiri, fotolithography na etching, a na-ahazi nhazi atụmatụ ahụ ka ọ bụrụ nhazi akụkụ atọ.

Ihe dị iche n'etiti mmiri etching na akọrọ etching

Mgbe usoro fotolithography gasịrị, mkpụrụ nke ekpughere na-agba mmiri ma ọ bụ akọrọ na usoro etching.

Mmiri etching na-eji ihe ngwọta na-ekpochapụ ma kpochapụ elu. Ọ bụ ezie na enwere ike ịhazi usoro a ngwa ngwa na ọnụ ala, ihe ọghọm ya bụ na nhazi nhazi ahụ dị ntakịrị ala. Ya mere, a mụrụ etching akọrọ gburugburu 1970. Akọrọ etching adịghị eji ihe ngwọta, ma na-eji gas kụrụ mkpụrụ n'elu na ọkọ ya, nke e ji elu nhazi ziri ezi.

"Isotropy" na "Anisotropy"

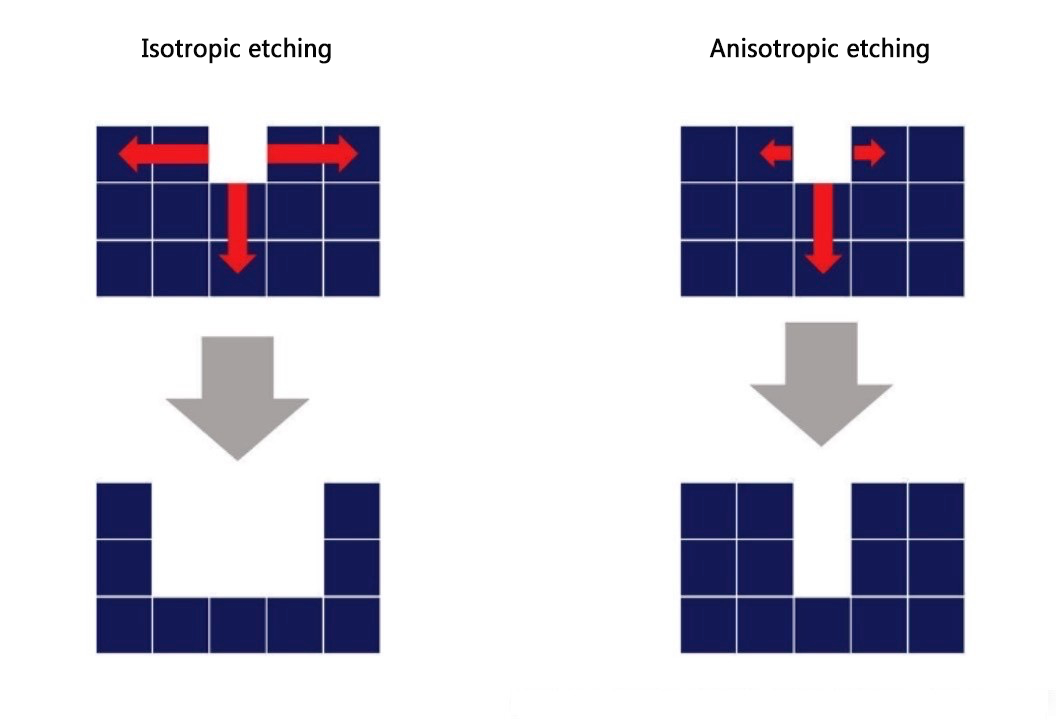

Mgbe ị na-ewebata ọdịiche dị n'etiti mmiri etching na akọrọ etching, okwu ndị dị mkpa bụ "isotropic" na "anisotropic". Isotropy pụtara na ihe anụ ahụ nke ihe na oghere adịghị agbanwe site na ntụziaka, na anisotropy pụtara na ọdịdị anụ ahụ nke ihe na oghere dịgasị iche na ntụziaka.

Isotropic etching pụtara na etching na-enweta site n'otu ego na gburugburu ebe ụfọdụ, na anisotropic etching pụtara na etching na-aga n'ihu n'ụzọ dị iche iche gburugburu otu ebe. Dịka ọmụmaatụ, na etching n'oge mmepụta semiconductor, a na-ahọrọkarị etching anisotropic ka ọ bụrụ naanị ebe a na-eche ihu ka a na-ehichapụ, na-ahapụ ntụziaka ndị ọzọ.

Foto nke "Isotropic Etch" na "Anisotropic Etch"

Foto nke "Isotropic Etch" na "Anisotropic Etch"

Wet etching na-eji chemicals.

Mmiri etching na-eji mmeghachi omume kemịkalụ n'etiti kemịkalụ na mkpụrụ. Site na usoro a, anisotropic etching agaghị ekwe omume, mana ọ siri ike karịa etching isotropic. Enwere ọtụtụ ihe mgbochi na nchikota nke ngwọta na ihe, na ọnọdụ ndị dị ka substrate okpomọkụ, ngwọta ntinye uche, na mgbakwunye ego ga-achịkwa nke ọma.

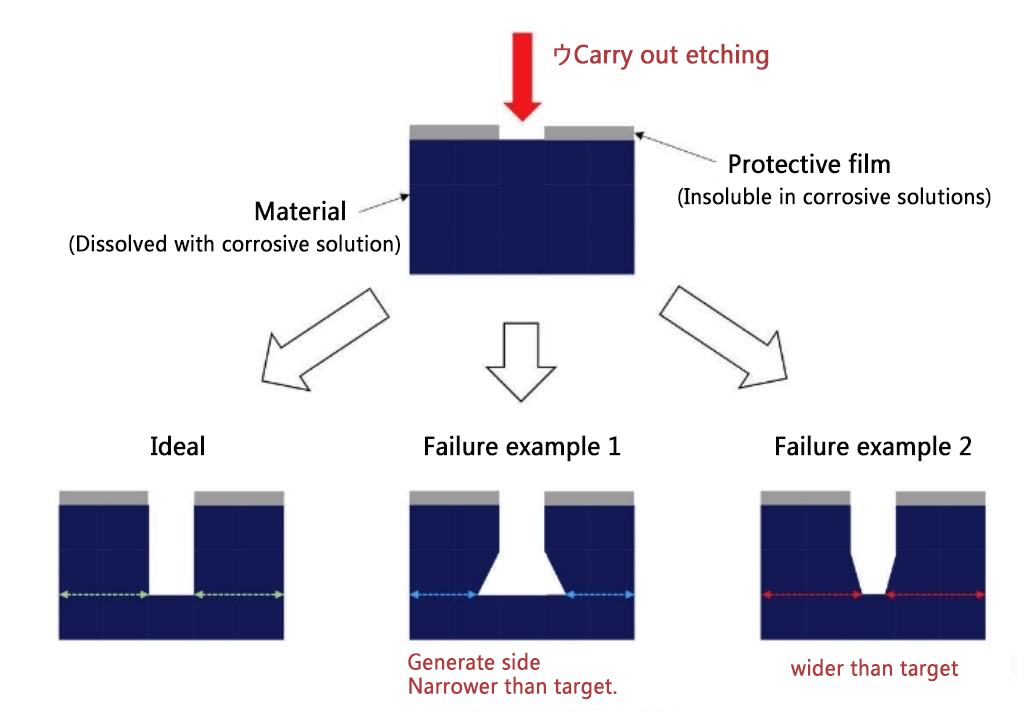

N'agbanyeghị otu esi edozi ọnọdụ ahụ nke ọma, etching mmiri siri ike iji nweta nhazi dị mma n'okpuru 1 μm. Otu ihe kpatara nke a bụ mkpa ijikwa akụkụ etching.

Ịkpụcha ala bụ ihe a na-akpọkwa n'ime ala. Ọbụlagodi na a na-atụ anya na a ga-agbaze ihe ahụ naanị n'akụkụ kwụ ọtọ (ntụziaka omimi) site na mmiri etching, ọ gaghị ekwe omume igbochi ihe ngwọta kpamkpam site na ịkụ n'akụkụ, ya mere mgbasa nke ihe ahụ na ntụziaka yiri ya ga-aga n'ihu. . N'ihi ihe a na-eme, mmiri mmiri etching na-emepụta ngalaba dị warara karịa obosara ebumnuche. N'ụzọ dị otú a, mgbe ị na-edozi ngwaahịa na-achọ kpọmkwem njikwa ugbu a, mmeghari ahụ dị ala na nke ziri ezi bụ nke a na-apụghị ịdabere na ya.

Ọmụmaatụ nke ọdịda nwere ike ime na Wet Etching

Ọmụmaatụ nke ọdịda nwere ike ime na Wet Etching

Kedu ihe kpatara etching akọrọ ji dị mma maka micromachining

A na-eji nkọwa nke Art Dry etching dabara adaba maka etching anisotropic na usoro nrụpụta semiconductor nke chọrọ nhazi nke ọma. A na-akpọkarị etching akọrọ dị ka reactive ion etching (RIE), nke nwekwara ike ịgụnye etching plasma na sputter etching n'ụzọ sara mbara, ma isiokwu a ga-elekwasị anya na RIE.

Iji kọwaa ihe kpatara etching anisotropic ji dị mfe na etching akọrọ, ka anyị lebakwuo anya na usoro RIE. Ọ dị mfe nghọta site n'ikewa usoro akọrọ akọrọ na ikpochapụ mkpụrụ ahụ n'ime ụdị abụọ: "chemical etching" na "etching anụ ahụ".

Kemịkalụ etching pụtara na nzọụkwụ atọ. Nke mbụ, a na-etinye gas ndị na-emeghachi omume n'elu. A na-emepụta ngwaahịa mmeghachi omume site na gas mmeghachi omume na ihe mkpụrụ, na n'ikpeazụ ngwaahịa mmeghachi omume na-desorbed. N'ime etching anụ ahụ na-esote, a na-akụ mkpụrụ ahụ n'ụzọ kwụ ọtọ na ala site n'itinye argon gas kwụ ọtọ na mkpụrụ.

Kemịkalụ etching na-apụta n'ụzọ isotropics, ebe etching anụ ahụ nwere ike ime anisotropically site na ịchịkwa ntụzịaka nke ngwa gas. N'ihi etching anụ ahụ a, akọrọ etching na-enye ohere ịchịkwa ntụziaka etching karịa mmiri etching.

Akọrọ na mmiri etching na-achọkwa otu ọnọdụ siri ike dị ka mmiri etching, ma ọ nwere nrụpụta dị elu karịa mmiri etching ma nwee ọtụtụ ihe dị mfe ịchịkwa. Ya mere, obi abụọ adịghị ya na etching akọrọ na-enye aka na mmepụta mmepụta ihe.

Kedu ihe kpatara eji achọ mmiri mmiri

Ozugbo ị ghọtara ihe etching akọrọ nke yiri ka ọ nwere ike ime ihe niile, ị nwere ike ịnọ na-eche ihe kpatara etching mmiri ka dị. Otú ọ dị, ihe kpatara ya dị mfe: etching mmiri na-eme ka ngwaahịa ahụ dị ọnụ ala.

Isi ihe dị iche n'etiti akọrọ etching na mmiri etching bụ ọnụ ahịa. Chemical ndị a na-eji etching mmiri adịghị oke ọnụ, a na-ekwukwa na ọnụ ahịa akụrụngwa n'onwe ya dị ihe dị ka 1/10 nke akụrụngwa etching akọrọ. Tụkwasị na nke ahụ, oge nhazi ahụ dị mkpụmkpụ ma nwee ike ịhazi ọtụtụ substrates n'otu oge, na-ebelata ụgwọ ọrụ mmepụta. N'ihi ya, anyị nwere ike idobe ọnụ ahịa ngwaahịa dị ala, na-enye anyị ohere karịa ndị asọmpi anyị. Ọ bụrụ na ihe ndị a chọrọ maka nhazi nhazi adịghị elu, ọtụtụ ụlọ ọrụ ga-ahọrọ etching mmiri maka mmepụta ihe siri ike.

E webatara usoro etching dị ka usoro nke na-ekere òkè na teknụzụ microfabrication. A na-ekewa usoro etching nke ọma ka ọ bụrụ mmiri etching na akọrọ etching. Ọ bụrụ na ọnụ ahịa dị mkpa, nke mbụ ka mma, ma ọ bụrụ na achọrọ microprocessing n'okpuru 1 μm, nke ikpeazụ ka mma. Dị ka o kwesịrị, enwere ike ịhọrọ usoro dabere na ngwaahịa a ga-emepụta na ọnụ ahịa, karịa nke ka mma.

Oge nzipu: Eprel 16-2024