Ngwa ike Semiconductor na-anọkwa n'ọnọdụ dị mkpa na sistemụ elektrọnik ike, ọkachasị n'ihe gbasara mmepe ngwa ngwa nke teknụzụ dị ka ọgụgụ isi, nkwukọrịta 5G na ụgbọ ala ume ọhụrụ, emeziwanye ihe achọrọ maka ha.

Silicon carbide(4H-SiC) aghọwo ihe dị mma maka ịmepụta ngwaọrụ semiconductor na-arụ ọrụ dị elu n'ihi uru ya dị ka bandgap obosara, ikuku okpomọkụ dị elu, ike nkwụsị elu dị elu, ọnụ ọgụgụ dị elu nke saturation, nkwụsi ike kemịkalụ na nguzogide radieshon. Otú ọ dị, 4H-SiC nwere isi ike dị elu, nnukwu brittleness, ike inertness kemịkal siri ike, na nnukwu nhazi ihe isi ike. Ogo elu nke wafer mkpụrụ ya dị oke mkpa maka ngwa ngwaọrụ buru ibu.

Ya mere, imeziwanye ogo elu nke 4H-SiC substrate wafers, karịsịa iwepụ oyi akwa mebiri emebi n'elu ebe a na-edozi wafer, bụ isi ihe na-eme ka ọ rụọ ọrụ nke ọma, nke dị ala na nke dị elu 4H-SiC substrate wafer nhazi.

Nnwale

Nnwale ahụ na-eji 4-inch N-ụdị 4H-SiC ingot toro site na usoro ụgbọ njem anụ ahụ, nke a na-ahazi site na ịcha waya, ichikota, egweri siri ike, ichicha dị mma na polishing, na-edekọ mwepu nke elu C na elu Si elu. na njedebe wafer ikpeazụ na usoro ọ bụla.

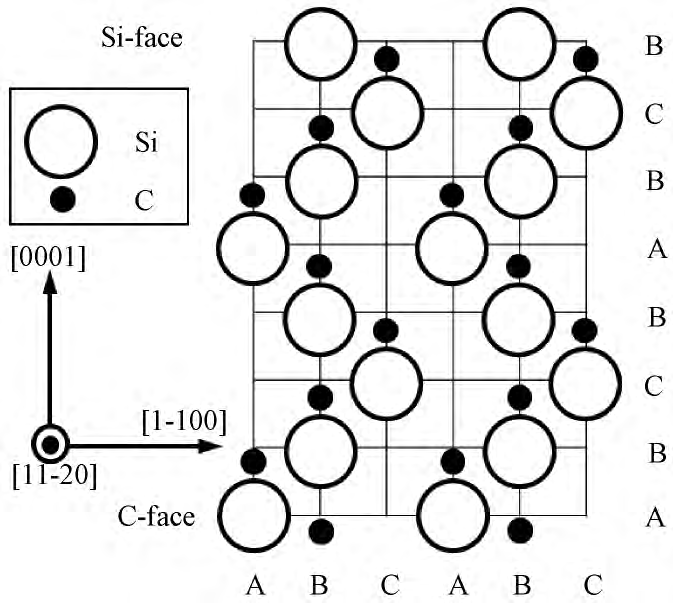

Onyonyo 1 Eserese atụmatụ nke nhazi kristal 4H-SiC

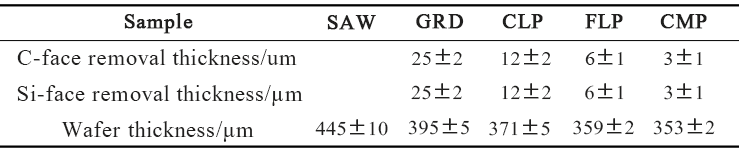

Ọgụgụ 2 ewepụrụ ịdị arọ site na C-akụkụ na Si-akụkụ nke 4H-SiC wafermgbe usoro nhazi dị iche iche na ọkpụrụkpụ nke wafer mgbe nhazi

E ji mara ọkpụrụkpụ, ọdịdị ọdịdị elu, adịghị ike na ihe arụrụ arụ nke wafer nke ọma site na ihe nnwale ihe nleba anya geometry dị iche iche, microscope dị iche iche, microscope atomiki, ngwa ihe nrịba elu na nanoindenter. Na mgbakwunye, a na-eji diffractometer X-ray dị elu iji nyochaa àgwà kristal nke wafer.

Usoro nnwale ndị a na ụzọ nnwale na-enye nkwado teknụzụ zuru ezu maka ịmụpụta ọnụego mwepụ ihe na ịdị mma elu n'oge nhazi nke 4H-SiC wafers.

Site na nnwale, ndị nchọpụta nyochara mgbanwe na ọnụego mwepụ ihe (MRR), morphology elu na roughness, yana akụrụngwa akụrụngwa na ogo kristal nke 4H-SiC wafersn'usoro nhazi dị iche iche (ịcha waya, ichikota, ihe siri ike, ichikota nke ọma, polishing).

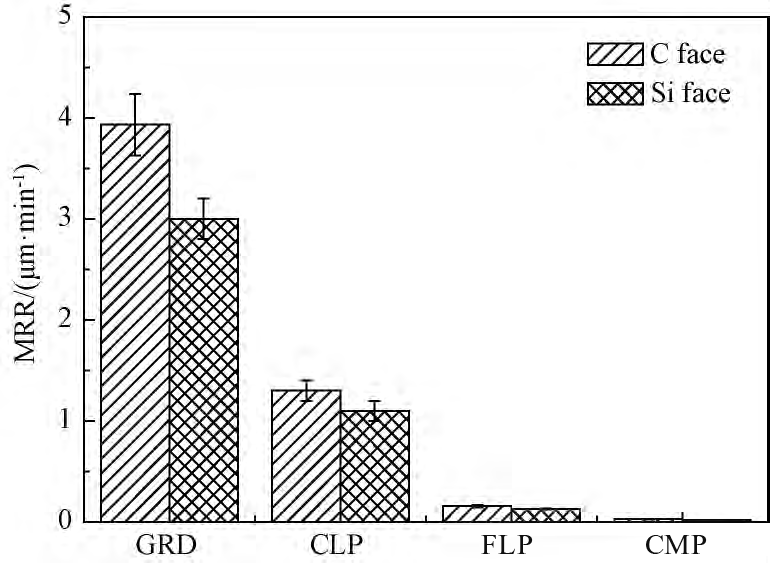

Ọgụgụ 3 Ọnụego mwepụ ihe onwunwe nke C-ihu na Si-face nke 4H-SiC waferna usoro nhazi dị iche iche

The ọmụmụ chọpụtara na n'ihi anisotropy nke n'ibu Njirimara nke dị iche iche crystal ihu nke 4H-SiC, e nwere ihe dị iche na MRR n'etiti C-ihu na Si-face n'okpuru otu usoro, na MRR nke C-ihu bụ budata elu karịa. nke Si-face. Site na ọganihu nke usoro nhazi ahụ, a na-eji nwayọọ nwayọọ emeziwanye ọdịdị ọdịdị elu na roughness nke 4H-SiC wafers. Mgbe polishing, Ra nke C-face bụ 0.24nm, na Ra nke Si-face ruru 0.14nm, nke nwere ike izute mkpa nke epitaxial ibu.

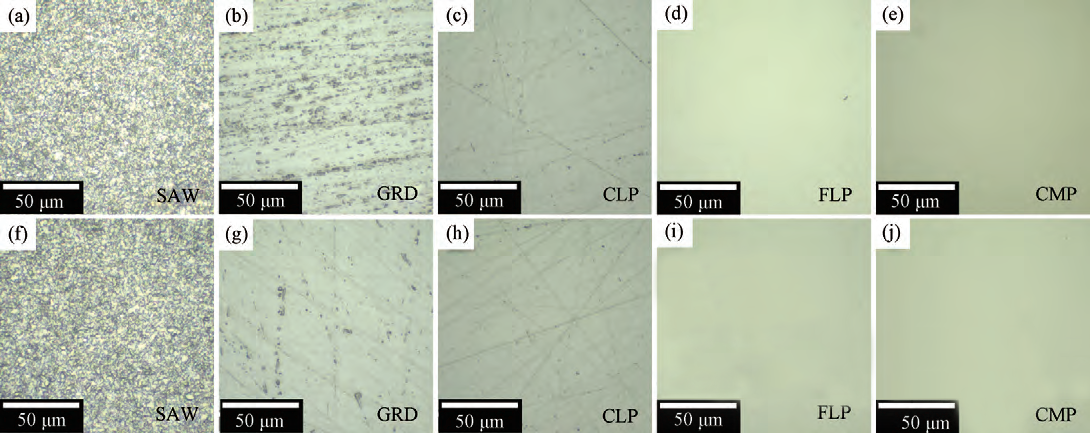

Ọgụgụ 4 Ihe onyonyo anya microscope nke elu C (a ~ e) na Si elu (f ~ j) nke 4H-SiC wafer mgbe usoro nhazi dị iche iche gachara.

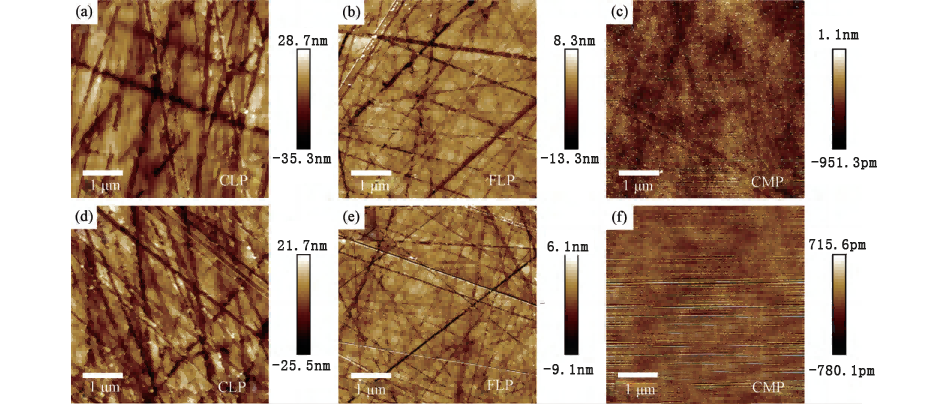

Ọgụgụ 5 Atomic Force microscope onyonyo nke elu C (a ~ c) na Si elu (d ~ f) nke 4H-SiC wafer mgbe usoro nhazi CLP, FLP na CMP gasịrị.

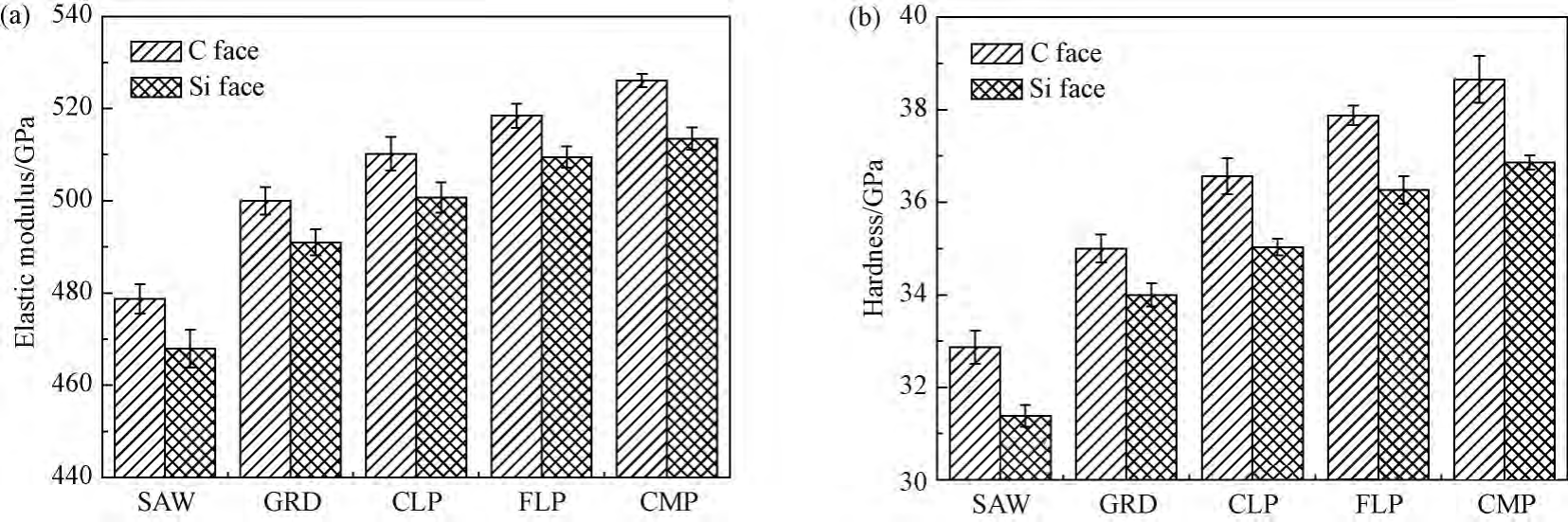

Ọgụgụ 6 (a) modulus na-agbanwe agbanwe na (b) ike nke elu C na Si elu nke 4H-SiC wafer mgbe usoro nhazi dị iche iche gasịrị.

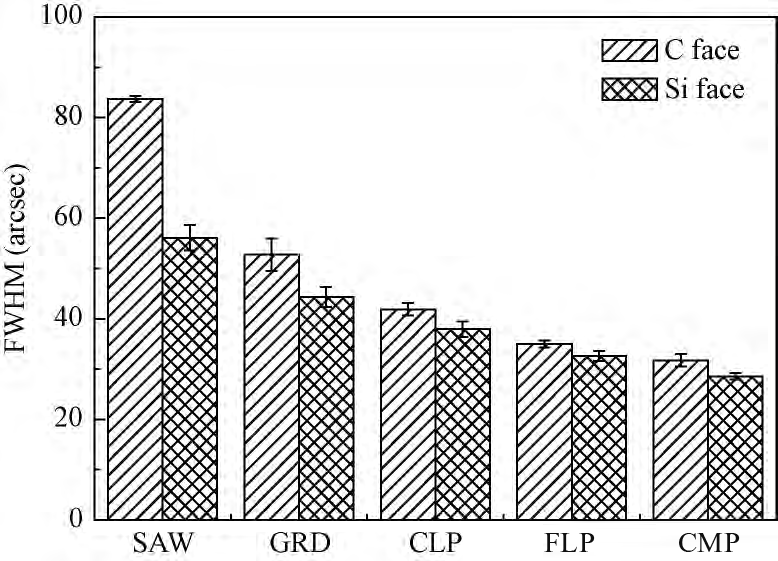

Nnwale ihe eji arụ ọrụ na-egosi na elu C nke wafer nwere ike ka njọ karịa ihe dị n'elu Si, oke mgbaji na-agbaji n'oge nhazi, iwepụ ngwa ngwa ngwa ngwa, yana morphology elu na adịghị mma. Iwepu oyi akwa mebiri emebi n'elu ala edoziri bụ isi ihe na-eme ka mma elu nke wafer dịkwuo mma. Enwere ike iji obosara nke ọkara ịdị elu nke 4H-SiC (0004) mkpagharị usoro iji kọwaa nke ọma na n'ụzọ ziri ezi ma nyochaa akwa mmebi elu nke wafer.

Ọgụgụ 7 (0004) na-ama jijiji ọkara obosara nke C-ihu na Si-face nke 4H-SiC wafer mgbe usoro nhazi dị iche iche.

Nsonaazụ nyocha na-egosi na enwere ike iwepụ oyi akwa mkpuchi elu nke wafer ahụ nke nta nke nta mgbe nhazi 4H-SiC wafer gasịrị, nke na-eme ka mma dị elu nke wafer dị mma ma na-enye ntụaka teknụzụ maka arụmọrụ dị elu, obere ọnwụ na nhazi dị elu. nke 4H-SiC mkpụrụ wafers.

Ndị na-eme nchọpụta na-edozi 4H-SiC wafers site na usoro nhazi dị iche iche dị ka ịcha waya, ichikota, ịhịa aka n'ahụ, nke ọma na-egweri na polishing, na-amụ mmetụta nke usoro ndị a na elu àgwà nke wafer.

Nsonaazụ na-egosi na site na ọganihu nke usoro nhazi ahụ, a na-eji nwayọọ nwayọọ na-emeziwanye ọdịdị ọdịdị elu na ihe siri ike nke wafer. Mgbe ihichachara, ịdị njọ nke C-face na Si-face ruru 0.24nm na 0.14nm n'otu n'otu, nke na-emezu ihe achọrọ nke uto epitaxial. The C-ihu nke wafer nwere ike ịda ogbenye karịa ihe Si-face, ma na-adịkarị mfe mgbaji agbaji n'oge nhazi, na-ebute ọdịdị ọdịdị elu na adịghị mma. Iwepu oyi akwa mmebi nke elu nke a na-ahazi bụ isi ihe na-eme ka mma elu nke wafer dịkwuo mma. Ọkara obosara nke 4H-SiC (0004) mkpagharị usoro nwere ike n'ụzọ ziri ezi na n'ụzọ ziri ezi mara elu mmebi oyi akwa nke wafer.

Nnyocha na-egosi na oyi akwa mebiri emebi n'elu 4H-SiC wafers nwere ike jiri nwayọọ nwayọọ wepụ ya site na nhazi 4H-SiC wafer, na-eme ka mma dị elu nke wafer dịkwuo mma, na-enye ntinye aka na nkà na ụzụ maka ịrụ ọrụ dị elu, obere ọnwụ, na elu- nhazi nhazi nke 4H-SiC substrate wafers.

Oge nzipu: Jul-08-2024