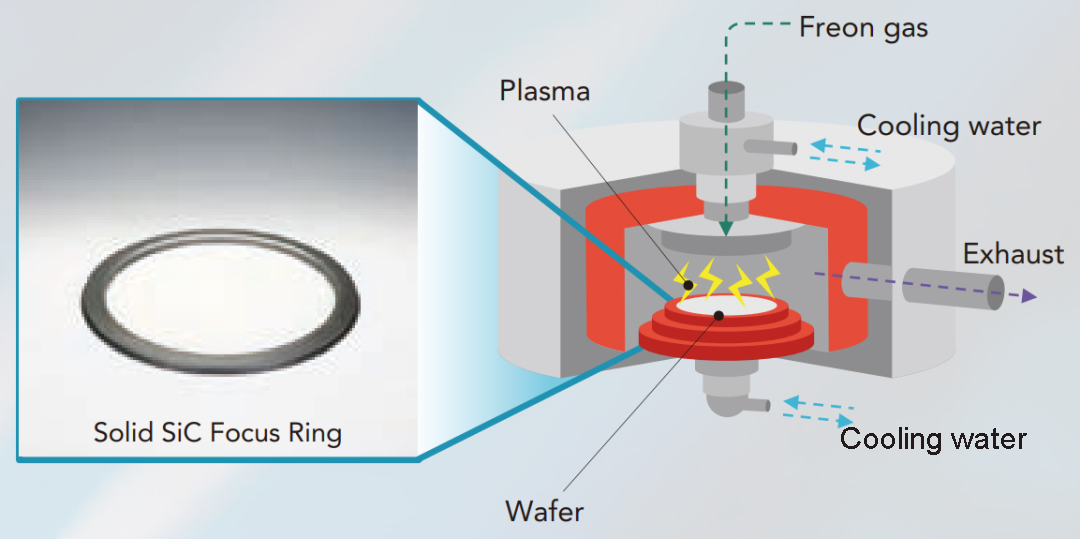

N'ime akụrụngwa etching plasma, ihe mejupụtara seramiiki na-arụ ọrụ dị oke mkpa, gụnyere nkemgbanaka mgbanaka.Nke mgbanaka mgbanaka, etinyere gburugburu wafer na na kọntaktị na ya, dị mkpa maka ilekwasị anya na plasma na wafer site na itinye voltaji na mgbanaka. Nke a na-eme ka otu usoro etching dịkwuo mma.

Ngwa nke mgbanaka mgbanaka SiC na igwe etching

Ngwa SiC CVDna etching igwe, dị kamgbanaka mgbanaka, gas ịsa isi, platens, na mgbanaka ihu, na-akwado ya n'ihi mmeghachi omume dị ala nke SiC na chlorine na fluorine nke etching gas na ihe omume ya, na-eme ka ọ bụrụ ihe dị mma maka ngwa etching plasma.

Uru nke SiC dị ka ihe mgbanaka mgbanaka

N'ihi mkpughe ozugbo na plasma n'ime ụlọ mmeghachi omume agụụ, ọ dị mkpa ka eme mgbanaka mgbanaka site na ihe na-eguzogide plasma. Mgbanaka mgbanaka mgbanaka ọdịnala, nke emere site na silicon ma ọ bụ quartz, na-ata ahụhụ site na nguzogide etching na-adịghị mma na plasma ndị dabere na fluorine, na-eduga na nrụrụ ngwa ngwa yana ibelata arụmọrụ.

Ntụle n'etiti Si na CVD SiC Focus Rings:

1. Njupụta dị elu:Na-ebelata olu etching.

2. Mgbagwoju anya sara mbara: Na-enye ihe mkpuchi dị mma.

3. Nrụpụta ọkụ dị elu na ọnụ ahịa mmụba dị ala: Na-eguzogide ujo ọkụ.

4. Ọganihu dị elu:Ezigbo iguzogide mmetụta igwe.

5. Oke isi ike: Uwe na-eguzogide corrosion.

SiC na-ekekọrịta conductivity eletriki nke silicon ka ọ na-enye nguzogide dị elu na ionic etching. Ka miniaturization sekit agbakwunyere na-aga n'ihu, ọchịchọ maka usoro etching nke ọma na-abawanye. Ngwa etching Plasma, ọkachasị ndị na-eji plasma capacitive jikọtara ọnụ (CCP), chọrọ ike plasma dị elu, na-emeSiC mgbanaka mgbanakana-ewu ewu na-esiwanye ike.

Si na CVD SiC mgbanaka mgbanaka mgbanaka:

| Oke | Silikon (Si) | CVD Silicon Carbide (SiC) |

| Njupụta (g/cm³) | 2.33 | 3.21 |

| Ọpụpụ Band (eV) | 1.12 | 2.3 |

| Nrụpụta ọkụ (W/cmºC) | 1.5 | 5 |

| Ọnụọgụ Mgbasawanye okpomọkụ (x10⁻⁶/°C) | 2.6 | 4 |

| Modulus Elastic (GPa) | 150 | 440 |

| Isi ike | Ala | Nke ka elu |

Usoro nrụpụta nke SiC Focus Rings

Na akụrụngwa semiconductor, CVD (Chemical Vapor Deposition) na-ejikarị emepụta ihe ndị SiC. A na-emepụta mgbanaka mgbanaka anya site na itinye SiC n'ụdị a kapịrị ọnụ site na ntunye uzuoku, na-esote nhazi usoro iji mepụta ngwaahịa ikpeazụ. A na-edozi oke ihe maka ntinye nkuku ka emechara nnwale dị ukwuu, na-eme paramita dị ka resistivity na-agbanwe agbanwe. Otú ọ dị, dị iche iche etching ngwá nwere ike ịchọ mgbanaka mgbanaka na iche iche resistivities, necessitating ọhụrụ ihe ruru nnwale maka onye ọ bụla nkọwa, nke na-ewe oge na-eri.

Site n'ịhọrọSiC mgbanaka mgbanakasiSemicera Semiconductor, ndị ahịa nwere ike nweta uru nke ogologo nnọchi cycles na elu arụmọrụ na-enweghị nnukwu mmụba na-eri.

Ngwa ngwa nhazi okpomọkụ (RTP).

Njirimara okpomọkụ pụrụ iche nke CVD SiC na-eme ka ọ dị mma maka ngwa RTP. Ngwa RTP, gụnyere mgbanaka ihu na platen, na-erite uru na CVD SiC. N'oge RTP, a na-etinye ọkụ ọkụ siri ike na wafer nke ọ bụla maka obere oge, na-esote ngwa ngwa jụrụ oyi. CVD SiC akụkụ mgbanaka, ịbụ ndị dị gịrịgịrị ma nwee oke okpomọkụ dị ala, anaghị ejide oke okpomọkụ, na-eme ka usoro ikpo ọkụ na oyi na-adịghị emetụta ha.

Ngwa Plasma Etching

Nnukwu nguzogide kemịkalụ CVD SiC na-eme ka ọ dabara maka ngwa etching. Ọtụtụ ụlọ etching na-eji efere nkesa CVD SiC gas kesaa gas etching, nwere ọtụtụ puku obere oghere maka mgbasa ozi plasma. Tụnyere ihe ndị ọzọ, CVD SiC nwere mmeghachi omume dị ala na chlorine na gas fluorine. Na akọrọ etching, CVD SiC components dị ka mgbanaka mgbanaka, ICP platen, mgbanaka oke, na isi ịsa ahụ na-ejikarị.

Mgbanaka mgbanaka SiC, yana voltaji etinyere ya maka itinye uche na plasma, ga-enwerịrị arụmọrụ zuru oke. Ejiri silicon mee ihe, mgbanaka mgbanaka na-ekpughere gas na-emegharị ihe nke nwere fluorine na chlorine, na-eduga na corrosion na-apụghị izere ezere. Mgbanaka mgbanaka SiC, yana nguzogide corrosion ha kachasị elu, na-enye ogologo ndụ ogologo ma e jiri ya tụnyere mgbanaka silicon.

Ntụnyere okirikiri ndụ:

Mgbanaka mgbanaka SiC:Dochie kwa ụbọchị 15 ruo 20.

Mgbanaka mgbanaka silicon:A na-edochi ya kwa ụbọchị 10 ruo 12.

N'agbanyeghị mgbanaka SiC ịbụ 2 ruo 3 ugboro dị ọnụ karịa mgbanaka silicon, ogologo ngbanwe okirikiri na-ebelata ụgwọ ọrụ nnọchi anya n'ozuzu ya, ebe a na-edochi akụkụ niile na-eyi n'ime ụlọ n'otu oge mgbe emepere ụlọ maka nnọchi mgbanaka mgbanaka.

Semicera Semiconductor's SiC Focus Rings

Semicera Semiconductor na-enye mgbanaka mgbanaka SiC n'ọnụ ahịa dị nso nke mgbanaka silicon, yana oge ndu ihe dịka ụbọchị 30. Site na ijikọ mgbanaka mgbanaka Semicera's SiC n'ime akụrụngwa etching plasma, arụmọrụ na ogologo ndụ na-abawanye nke ọma, na-ebelata ụgwọ ọrụ mmezi yana ịkwalite nrụpụta nrụpụta. Na mgbakwunye, Semicera nwere ike hazie resistivity nke mgbanaka mgbanaka iji mezuo ihe ndị ahịa chọrọ.

Site na ịhọrọ mgbanaka mgbanaka mgbanaka SiC sitere na Semicera Semiconductor, ndị ahịa nwere ike nweta uru nke ogologo oge nnọchi ogologo yana arụmọrụ dị elu na-enweghị mmụba dị ukwuu na ọnụ ahịa.

Oge nzipu: Jul-10-2024