Uto ngwa ngwa nke SiC Single Crystal IjiCVD-SiC nnukwuIsi mmalite site na usoro Sublimation

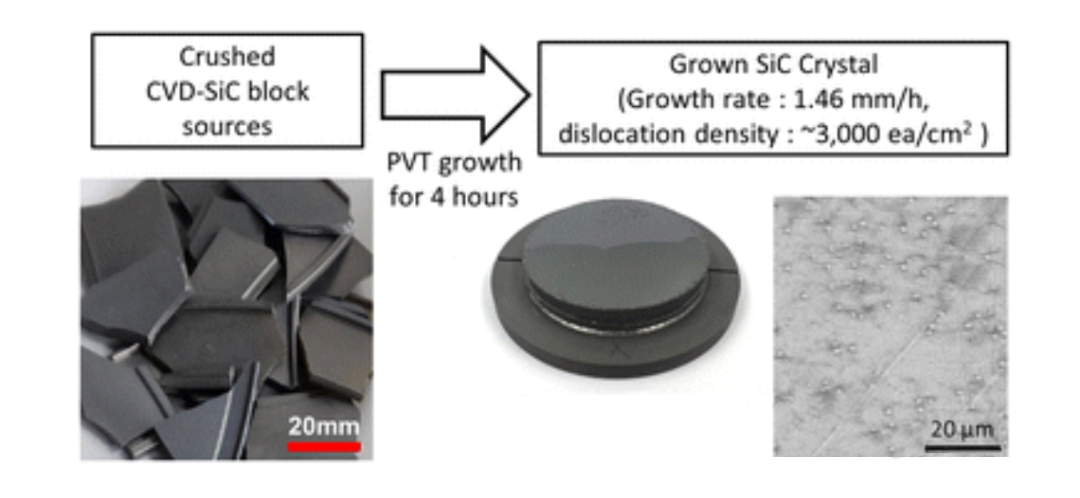

Site na iji megharịaIhe mgbochi CVD-SiCdị ka isi iyi SiC, kristal SiC na-eto nke ọma na ọnụego 1.46 mm / h site na usoro PVT. Igwe micropipe nke kristal toro eto na njupụta nke nchụpụ na-egosi na n'agbanyeghị oke uto, ogo kristal dị mma.

Silicon carbide (SiC)bụ semiconductor obosara-bandgap nwere ọmarịcha ihe maka ngwa na voltaji dị elu, ike dị elu na ugboro ole. Ọchịchọ ya etoola ngwa ngwa n'afọ ndị na-adịbeghị anya, ọkachasị na ngalaba semiconductor ike. Maka ngwa semiconductor ike, SiC otu kristal na-etolite site n'ịkwalite isi iyi SiC dị ọcha na 2100-2500 Celsius C, wee na-atụgharị na kristal mkpụrụ site na iji usoro ụgbọ njem anụ ahụ (PVT), na-esote nhazi iji nweta otu mkpụrụ kristal na wafers. . Omenala,SiC kristalA na-etolite site na iji usoro PVT na mmụba nke 0.3 ruo 0.8 mm / h iji chịkwaa crystallinity, nke na-adị nwayọọ ma e jiri ya tụnyere ihe ndị ọzọ kristal na-eji na ngwa semiconductor. Mgbe kristal SiC na-etolite n'ogo dị elu site na iji usoro PVT, nbibi dị mma gụnyere carbon inclusions, belata ịdị ọcha, uto polycrystalline, nhazi oke ọka, na nkwụsịtụ na ntụpọ porosity ewepụghị. Ya mere, uto ngwa ngwa nke SiC emebebeghị, yana ọnụ ọgụgụ nke SiC na-eto ngwa ngwa abụrụla nnukwu ihe mgbochi na mmepụta nke mkpụrụ ala SiC.

N'aka nke ọzọ, akụkọ ndị na-adịbeghị anya banyere uto ngwa ngwa nke SiC na-eji usoro ikuku mmiri ọkụ dị elu (HTCVD) karịa usoro PVT. Usoro HTCVD na-eji vapor nwere Si na C dị ka isi iyi SiC na reactor. Ejibeghị HTCVD maka nnukwu mmepụta nke SiC ma chọọ nyocha ọzọ na mmepe maka ịzụ ahịa. N'ụzọ na-akpali mmasị, ọbụlagodi n'ogo dị elu nke ~ 3 mm / h, SiC otu kristal nwere ike iji ezigbo kristal tolite site na iji usoro HTCVD. Ka ọ dị ugbu a, ejirila akụrụngwa SiC na usoro semiconductor n'okpuru gburugburu ebe siri ike nke chọrọ njikwa usoro ịdị ọcha dị oke elu. Maka ngwa usoro semiconductor, ~ 99.9999% (~ 6N) akụrụngwa SiC dị ọcha na-akwadokarị site na usoro CVD sitere na methyltrichlorosilane (CH3Cl3Si, MTS). Agbanyeghị, n'agbanyeghị ịdị ọcha dị elu nke akụrụngwa CVD-SiC, a tụfuru ha mgbe ejiri ya. N'oge na-adịbeghị anya, a na-ewere akụkụ CVD-SiC tụfuru dị ka isi mmalite SiC maka uto kristal, ọ bụ ezie na ụfọdụ usoro mgbake gụnyere nchicha na ịdị ọcha ka chọrọ iji gboo nnukwu ihe na-achọ isi iyi uto kristal. N'ime ọmụmụ ihe a, anyị na-eji ihe mgbochi CVD-SiC atụfuru iji megharịa ihe dịka isi iyi maka kristal SiC na-eto eto. A na-akwado ihe mgbochi CVD-SiC maka otu uto kristal dị ka ihe mgbochi a na-achịkwa nke ukwuu, dị nnọọ iche na ọdịdị na nha ma e jiri ya tụnyere SiC ntụ ntụ a na-ejikarị eme ihe na usoro PVT, ya mere a na-atụ anya na omume SiC otu kristal na-eto eto ga-abụ nke ukwuu. dị iche. Tupu ịme nyocha nke otu kristal SiC, a na-eme emume kọmpụta iji nweta ọnụego uto dị elu, ma hazie mpaghara ọkụ ahụ maka otu uto kristal. Mgbe uto kristal gasịrị, a na-enyocha kristal ndị toro eto site na ntanetị akụkụ, micro-Raman spectroscopy, nnukwu mkpebi X-ray diffraction, na synchrotron white beam X-ray topography.

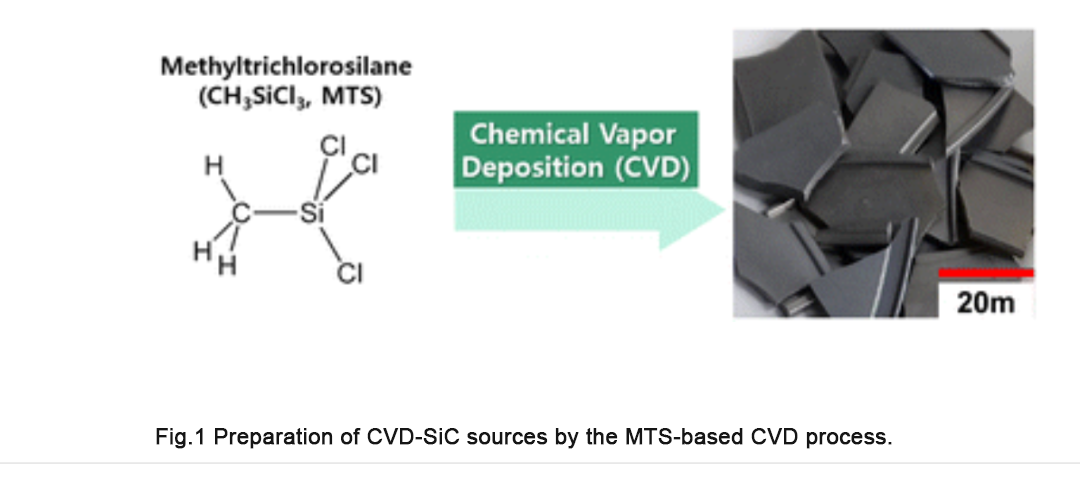

Ọgụgụ 1 na-egosi isi iyi CVD-SiC ejiri maka uto PVT nke kristal SiC n'ọmụmụ ihe a. Dị ka akọwara na mmalite, CVD-SiC components sitere na MTS site na usoro CVD na-emepụta maka iji semiconductor mee ihe site na nhazi nhazi. A doped N na usoro CVD iji nweta conductivity maka ngwa usoro semiconductor. Mgbe ejiri ya na usoro semiconductor, a gbajiri akụkụ CVD-SiC iji dozie isi iyi maka uto kristal, dị ka egosiri na eserese 1. A kwadebere isi iyi CVD-SiC dị ka efere nwere oke ọkpụrụkpụ nke ~ 0.5 mm na nkezi urughuru nha. 49.75 mm.

Ọgụgụ 1: CVD-SiC isi mmalite nke usoro CVD dabeere na MTS kwadoro.

Ọgụgụ 1: CVD-SiC isi mmalite nke usoro CVD dabeere na MTS kwadoro.

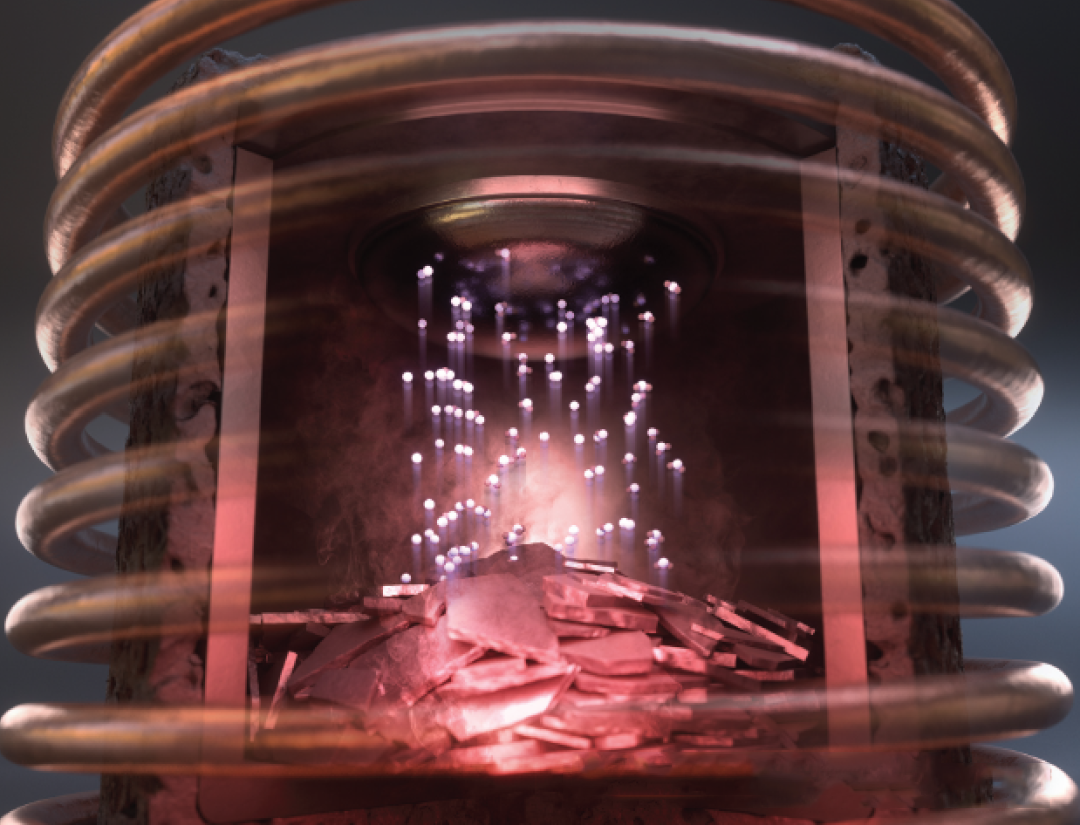

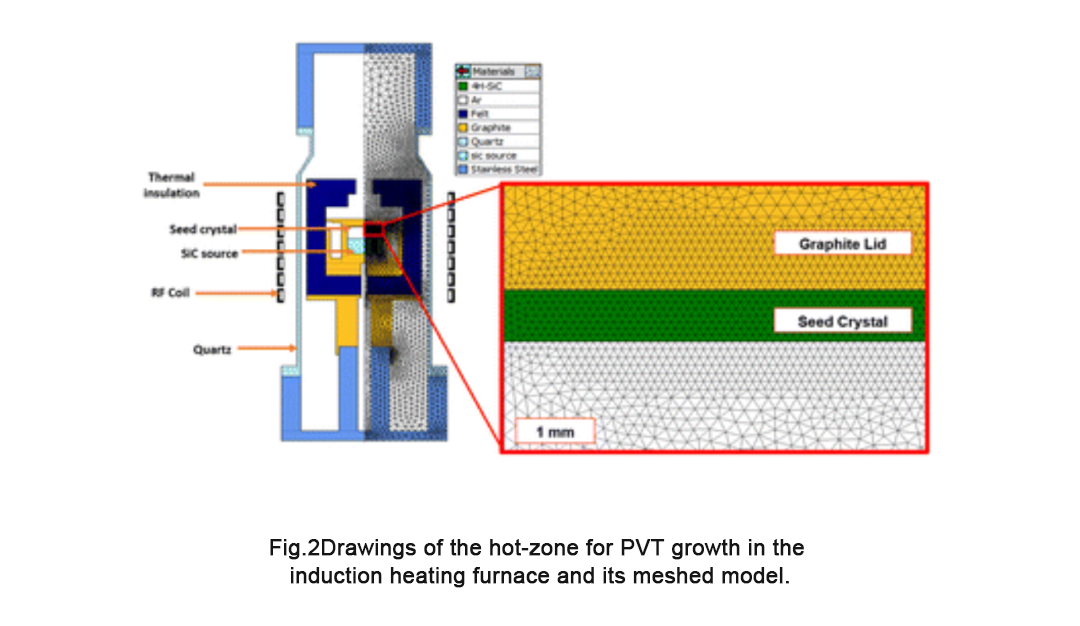

N'iji isi iyi CVD-SiC nke egosiri na eserese 1, usoro PVT toro kristal SiC n'ime ọkụ ọkụ induction. Iji nyochaa nkesa okpomọkụ na mpaghara okpomọkụ, a na-eji koodu ịme anwansị azụmahịa VR-PVT 8.2 (STR, Republic of Serbia) mee ihe. Emebere ihe nrụpụta nke nwere mpaghara thermal dị ka ụdị axisymmetric 2D, dịka egosiri na eserese 2, yana ụdị ntupu ya. A na-egosi ihe niile eji eme ihe na simulation na Figure 2, a na-edekwa ihe onwunwe ha na Tebụl 1. Dabere na nsonaazụ simulation, kristal SiC na-eto site na iji usoro PVT na okpomọkụ nke 2250-2350 ° C na ikuku Ar na. 35 Torr maka awa 4. Ejiri 4° kwụsịrị-axis 4H-SiC wafer dị ka mkpụrụ SiC. A na-enyocha kristal toro eto site na micro-Raman spectroscopy (Witec, UHTS 300, Germany) na nnukwu mkpebi XRD (HRXRD, X'Pert-PROMED, PANalytical, Netherlands). A tụlere mkpokọta adịghị ọcha dị na kristal SiC toro site na iji spectrometry ion mass spectrometry (SIMS, Cameca IMS-6f, France). A tụlere njupụta nke kristal toro eto site na iji synchrotron white beam X-ray topography na Pohang Light Source.

Onyonyo 2: Eserese mpaghara thermal na ụdị ntupu nke uto PVT n'ime ọkụ ọkụ induction.

Onyonyo 2: Eserese mpaghara thermal na ụdị ntupu nke uto PVT n'ime ọkụ ọkụ induction.

Ebe ọ bụ na ụzọ HTCVD na PVT na-eto kristal n'okpuru usoro nhazi nke gas siri ike na n'ihu uto, ọganihu ngwa ngwa ngwa ngwa nke SiC site na usoro HTCVD kpaliri ihe ịma aka nke uto ngwa ngwa nke SiC site na usoro PVT n'ime ọmụmụ ihe a. Usoro HTCVD na-eji isi iyi gas na-achịkwa ngwa ngwa, ebe usoro PVT na-eji isi iyi siri ike nke na-adịghị achịkwa ọsọ ọsọ. Enwere ike ịchịkwa ọnụ ọgụgụ na-erugharị na-eto eto n'ihu n'ihu na usoro PVT site na ọnụ ọgụgụ sublimation nke isi iyi siri ike site na njikwa nkesa okpomọkụ, ma njikwa ziri ezi nke nkesa okpomọkụ na usoro ọganihu bara uru adịghị mfe.

Site n'ịbawanye okpomọkụ isi iyi na reactor PVT, ọnụ ọgụgụ uto nke SiC nwere ike ịba ụba site n'ịbawanye ọnụego sublimation nke isi iyi. Iji nweta uto kristal kwụsiri ike, njikwa okpomọkụ n'ihu uto dị oke mkpa. Iji mee ka ọganihu na-eto eto na-enweghị ịmepụta polycrystals, ọ dị mkpa ka e nweta gradient dị elu na-eto eto n'ihu, dị ka e gosiri site na uto SiC site na usoro HTCVD. Ezughị oke vetikal okpomọkụ conduction na azụ nke okpu kwesịrị dissipate na akwakọba okpomọkụ na ibu n'ihu site thermal radieshon ka ibu elu, na-eduga na e guzobere ngafe na-ebupụta, ie, polycrystalline ibu.

Ma uka nyefe na recrystallization Filiks na PVT usoro yiri nnọọ ka HTCVD usoro, ọ bụ ezie na ha dị iche na SiC isi iyi. Nke a pụtara na uto ngwa ngwa nke SiC bụkwa nke a ga-enweta ma ọ bụrụ na ọnụego sublimation nke isi iyi SiC dị elu nke ọma. Agbanyeghị, inweta otu kristal SiC dị elu n'okpuru ọnọdụ uto dị elu site na usoro PVT nwere ọtụtụ ihe ịma aka. Ntụ ntụ azụmahịa na-enwekarị ngwakọta nke obere ihe na nnukwu. N'ihi ọdịiche ike dị n'elu, obere ihe nwere oke adịghị ọcha na nke dị elu n'ihu nnukwu ahụ, na-eduga na oke adịghị ọcha na mmalite mmalite nke kristal. Na mgbakwunye, dị ka SiC siri ike na-emebi n'ụdị uzuoku dị ka C na Si, SiC2 na Si2C na oke okpomọkụ, C siri ike na-apụtaghị mgbe isi iyi SiC dị elu na usoro PVT. Ọ bụrụ na C siri ike a kpụrụ akpụ dị ntakịrị na ọkụ zuru oke, n'okpuru ọnọdụ uto ngwa ngwa, obere C, nke a maara dị ka "uzuzu C," nwere ike ibuga n'elu kristal site na nnyefe siri ike nke ukwuu, na-ebute ntinye na kristal toro eto. Ya mere, iji belata ihe ndị na-adịghị ọcha na uzuzu C, a ga-achịkwa nha nha nke isi iyi SiC ka ọ bụrụ dayameta nke na-erughị 200 μm, na ọnụego uto ekwesịghị gafere ~ 0.4 mm / h iji nọgide na-ebufe ngwa ngwa ma wepụ ihe na-ese n'elu mmiri. C uzuzu. Igwe adịghị ọcha na uzuzu C na-eduga na mmebi nke kristal SiC toro eto, nke bụ isi ihe mgbochi na uto ngwa ngwa nke SiC site na usoro PVT.

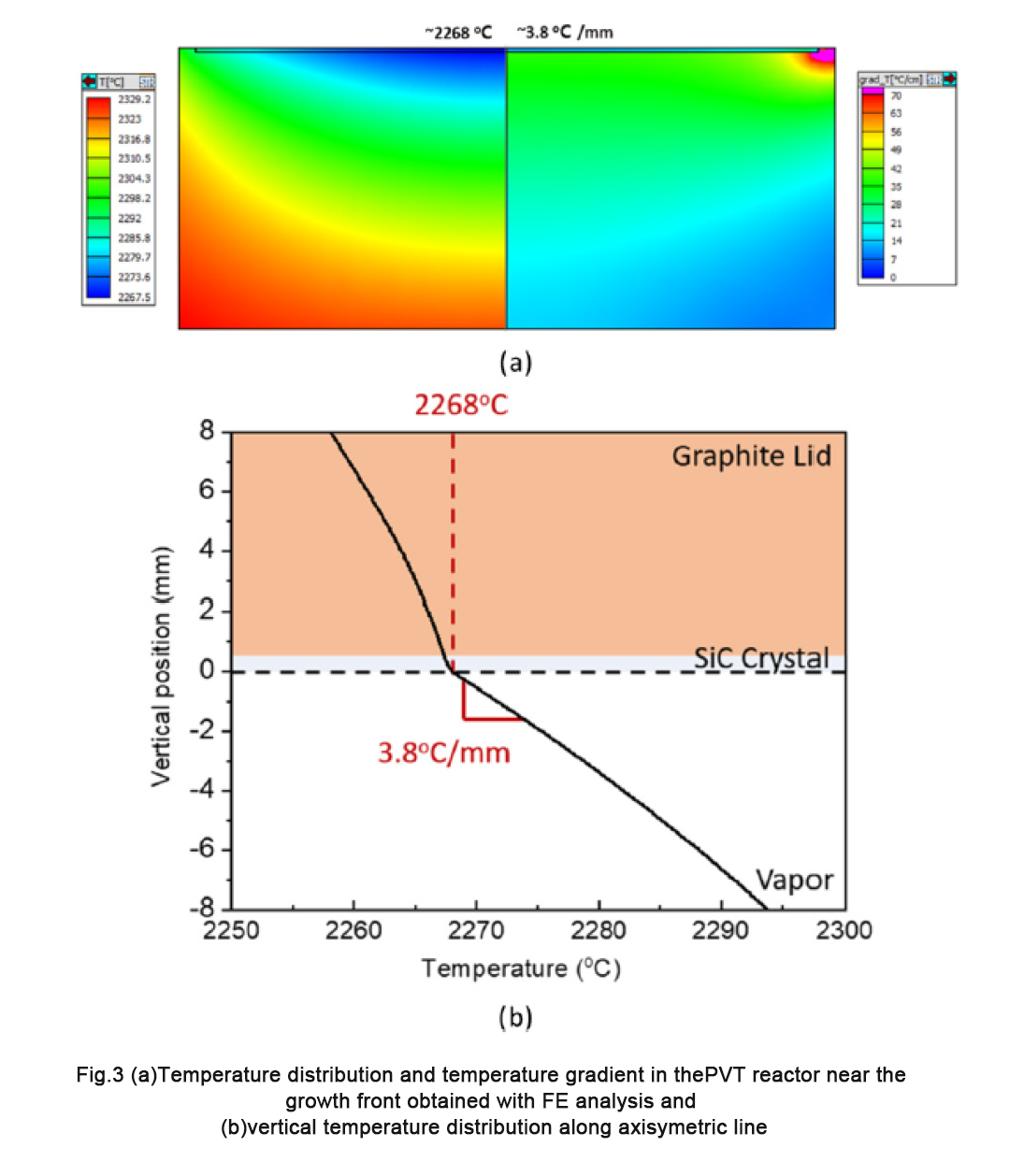

N'ime ọmụmụ ihe a, a na-eji isi mmalite CVD-SiC gbajiri agbaji na-enweghị obere irighiri ihe, na-ewepụ uzuzu C na-ese n'elu mmiri n'okpuru nnyefe siri ike. Ya mere, e mere nhazi mpaghara thermal site na iji usoro PVT simulation multiphysics iji nweta uto SiC ngwa ngwa, na nkesa okpomọkụ na okpomọkụ nke simulated na-egosi na foto 3a.

Ọgụgụ 3: (a) Nkesa okpomọkụ na gradient okpomọkụ dị nso n'ihu n'ihu PVT reactor nwetara site na nyocha nke njedebe, na (b) nkesa okpomọkụ kwụ ọtọ n'akụkụ ahịrị axisymmetric.

E jiri ya tụnyere ntọala mpaghara thermal a na-ahụkarị maka kristal SiC na-eto eto na ọnụego uto nke 0.3 ruo 0.8 mm / h n'okpuru obere okpomọkụ nke na-erughị 1 Celsius C / mm, ntọala mpaghara thermal na ọmụmụ a nwere nnukwu gradient okpomọkụ nke ~ ∼ 3.8C/mm n'oge uto okpomọkụ nke ~ 2268°C. Uru gradient okpomọkụ dị n'ọmụmụ ihe a tụnyere uto ngwa ngwa nke SiC na ọnụego 2.4 mm / h site na iji usoro HTCVD, ebe a na-edozi gradient okpomọkụ ka ọ bụrụ 14 °C / mm. Site na nkesa okpomọkụ kwụ ọtọ nke egosiri na foto 3b, anyị kwadoro na ọ dịghị mgbanwe mgbanwe okpomọkụ nke nwere ike ịmepụta polycrystals dị nso n'ihu uto, dị ka akọwara na akwụkwọ.

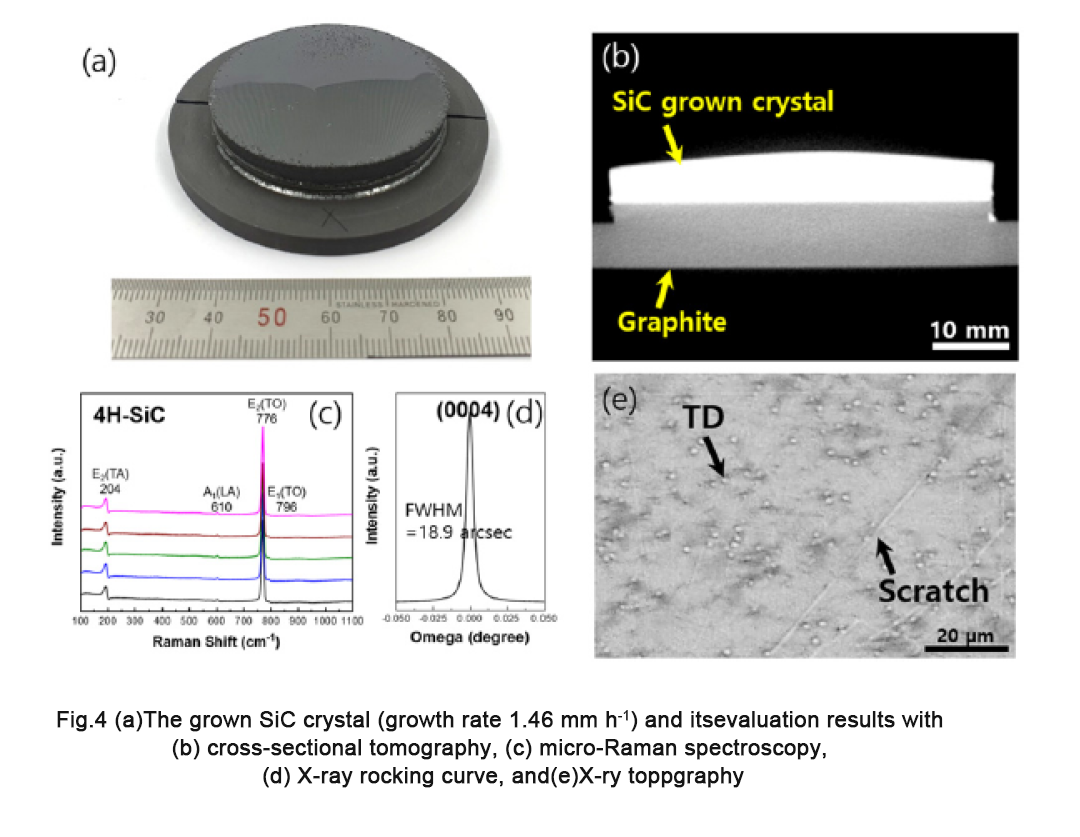

N'iji usoro PVT, kristal SiC sitere na isi iyi CVD-SiC maka awa 4, dị ka egosiri na 2 na 3. A na-egosi onye nnọchiteanya SiC crystal uto sitere na SiC toro na Figure 4a. Ọkpụrụkpụ na ọnụego uto nke kristal SiC egosiri na eserese 4a bụ 5.84 mm na 1.46 mm / h, n'otu n'otu. Achọpụtara mmetụta nke isi iyi SiC na àgwà, polytype, morphology, na ịdị ọcha nke kristal SiC toro eto nke egosiri na Figure 4a, dị ka egosiri na 4b-e. Onyonyo onyonyo nke dị n'ofe nke dị na eserese 4b na-egosi na uto kristal ahụ nwere ọdịdị convex n'ihi ọnọdụ uto dị ala. Otú ọ dị, micro-Raman spectroscopy na Figure 4c chọpụtara kristal toro dị ka otu akụkụ nke 4H-SiC na-enweghị ihe ọ bụla polytype gụnyere. Uru FWHM nke ọnụ ọgụgụ kachasị elu (0004) enwetara site na nyocha nyocha nke mkpagharị X-ray bụ 18.9 arcseconds, na-akwadokwa ịdị mma kristal dị mma.

Ọgụgụ 4: (a) SiC kristal toro (ọnụego uto nke 1.46 mm / h) na nsonaazụ nyocha ya na (b) tomography cross-section, (c) micro-Raman spectroscopy, (d) X-ray rocking curve, na ( e) Ihe onyonyo nke X-ray.

Onyonyo 4e na-egosi topography X-ray na-acha ọcha na-achọpụta ncha na ihe ndọpụ eri na wafer a na-egbu maramara nke kristal toro. A tụrụ njupụta njupụta nke kristal toro ka ọ bụrụ ~ 3000 ea/cm², dị ntakịrị elu karịa njupụta nke kristal mkpụrụ, nke bụ ~ 2000 ea/cm². Ekwenyere na kristal toro eto nwere njupụta dislocation dị obere, ma e jiri ya tụnyere ịdị mma kristal nke wafer azụmahịa. N'ụzọ na-akpali mmasị, a nwetara uto ngwa ngwa nke kristal SiC site na iji usoro PVT nwere isi iyi CVD-SiC gbajiri agbaji n'okpuru nnukwu gradient okpomọkụ. Nkwakọba nke B, Al, na N na kristal tolitere bụ 2.18 × 10¹⁶, 7.61 × 10¹⁵, na 1.98 × 10¹⁹ atọm/cm³, n'otu n'otu. Ntụnye P na kristal toro dị n'okpuru oke nchọpụta (<1.0 × 10¹⁴ atọm/cm³). Ọnụ ọgụgụ adịghị ọcha dị obere maka ndị na-ebu ụgwọ, ma e wezụga N, bụ nke e kpachapụrụ anya mee n'oge usoro CVD.

Ọ bụ ezie na uto kristal na ọmụmụ ihe a dị ntakịrị na-atụle ngwaahịa azụmahịa, ihe ngosi na-aga nke ọma nke uto SiC ngwa ngwa na àgwà kristal dị mma na-eji isi iyi CVD-SiC site na usoro PVT nwere mmetụta dị ịrịba ama. Ebe ọ bụ na isi mmalite CVD-SiC, n'agbanyeghị ọmarịcha ihe onwunwe ha, na-akwụ ụgwọ site n'ịmegharị ihe ndị a tụfuru, anyị na-atụ anya na ojiji ha zuru ebe niile dị ka isi iyi SiC na-ekwe nkwa iji dochie isi mmalite ntụ ntụ SiC. Iji tinye isi mmalite CVD-SiC maka uto ngwa ngwa nke SiC, na-eme ka nkesa okpomọkụ dị na sistemụ PVT chọrọ, na-ebute ajụjụ ndị ọzọ maka nyocha n'ọdịnihu.

Mmechi

N'ime ọmụmụ ihe a, a na-enweta ihe ngosi na-aga nke ọma nke uto kristal SiC ngwa ngwa site na iji cVD-SiC blocks n'okpuru ọnọdụ gradient dị elu site na usoro PVT. N'ụzọ na-akpali mmasị, ọganihu ngwa ngwa nke kristal SiC nwetara site na iji usoro PVT dochie isi iyi SiC. A na-atụ anya na usoro a ga-abawanye nrụpụta nnukwu mmepụta nke otu kristal SiC, na-emecha belata ọnụ ahịa otu nke ihe ndị SiC na ịkwalite ojiji nke ngwaọrụ ike na-arụ ọrụ dị elu.

Oge nzipu: Jul-19-2024