Otu nkọwa

N'ime usoro mmepụta sekit jikọtara ọnụ, fotolithography bụ usoro bụ isi nke na-ekpebi ọkwa ntinye nke sekit agbakwunyere. Ọrụ nke usoro a bụ iji ikwesị ntụkwasị obi na-ebufe ma bufee ozi eserese sekit site na nkpuchi (nke a na-akpọkwa nkpuchi) na mkpụrụ ihe semiconductor.

Ụkpụrụ bụ isi nke usoro fotolithography bụ iji mmeghachi omume photochemical nke photoresist kpuchie n'elu nke mkpụrụ ahụ iji dekọọ ụkpụrụ sekit na ihe mkpuchi ahụ, si otú ahụ nweta nzube nke ịnyefe usoro sekit agbakwunyere site na nhazi ahụ gaa na mkpụrụ.

Isi usoro nke fotolithography

Nke mbụ, a na-etinye photoresist n'elu ihe nkedo site na iji igwe mkpuchi;

Mgbe ahụ, a na-eji igwe fotolithography kpughee mkpụrụ nke ejiri fotoresist kpuchie ya, a na-ejikwa usoro mmeghachi omume nke photochemical iji dekọọ ozi ihe nkpuchi nke igwe fotolithography na-ebufe, na-emecha nnyefe ntụkwasị obi, nnyefe na mmegharị nke ihe nkpuchi ahụ na mkpụrụ;

N'ikpeazụ, a na-eji onye nrụpụta mepụta mkpụrụ nke ekpughere iji wepụ (ma ọ bụ jigide) fotoresisist nke na-enweta mmeghachi omume fotochemical mgbe ekpughere ya.

Usoro fotolithography nke abụọ

Iji nyefee usoro sekit a haziri na ihe mkpuchi na silicon wafer, a ga-ebu ụzọ nweta mbufe site na usoro ikpughe, mgbe ahụ, a ga-enwetarịrị usoro silicon site na usoro etching.

Ebe ọ bụ na ìhè nke mpaghara usoro fotolithography na-eji isi iyi na-acha odo odo nke ihe ndị na-ese foto na-enweghị mmetụta, a na-akpọkwa ya ebe ìhè odo.

A na-eji fotolithography nke mbụ mee ihe na ụlọ ọrụ obibi akwụkwọ ma bụrụ teknụzụ bụ isi maka ịmepụta PCB n'oge. Kemgbe 1950s, fotolithography ejirila nwayọọ nwayọọ bụrụ teknụzụ bụ isi maka ịnyefe ụkpụrụ na nrụpụta IC.

Isi ihe na-egosi usoro lithography gụnyere mkpebi, nghọta, izi ezi machie, ọnụego ntụpọ, wdg.

Ihe kachasị dị oke egwu na usoro fotolithography bụ fotoresisist, nke bụ ihe na-emetụ n'ahụ. Ebe ọ bụ na uche nke onye na-ese foto na-adabere n'ịdị elu nke ìhè ọkụ, a na-achọ ihe dị iche iche nke photoresist maka usoro fotolithography dị ka g / i line, 248nm KrF, na 193nm ArF.

Isi usoro nke usoro fotolithography ahụkarị gụnyere usoro ise

:

-Base ihe nkiri nkwadebe;

-Tinye photoresist na achịcha dị nro;

- Nhazi, mkpughe na ịsa achịcha mgbe ekpughere;

- Mepụta ihe nkiri siri ike;

-Nchọpụta mmepe.

(1)Nkwadebe ihe nkiri ndabere: tumadi ihicha na akpịrị ịkpọ nkụ. N'ihi na ihe ọ bụla na-emerụ emerụ ga-ebelata nkwụsị n'etiti photoresist na wafer, nhicha nke ọma nwere ike imeziwanye njikọ dị n'etiti wafer na photoresist.

(2)Ihe mkpuchi fotoresisist: A na-enweta nke a site n'ịtụgharị silicon wafer. Ndị na-ese foto dị iche iche chọrọ usoro usoro mkpuchi dị iche iche, gụnyere ọsọ ntụgharị, ọkpụrụkpụ fotoresist, na okpomọkụ.

Nri dị nro: Ime achịcha nwere ike imeziwanye njikọ dị n'etiti photoresist na silicon wafer, yana ịdị n'otu nke ọkpụrụkpụ fotoresist, nke bara uru maka njikwa ziri ezi nke akụkụ geometric nke usoro etching na-esote.

(3)Nhazi na ikpughe: Nhazi na ikpughe bụ usoro kachasị mkpa na usoro fotolithography. Ha na-ezo aka n'ịhazi ụkpụrụ nkpuchi ahụ na ụkpụrụ dị na wafer (ma ọ bụ ụkpụrụ oyi akwa n'ihu), wee jiri ọkụ na-egbukepụ ya. Ike ọkụ na-eme ka ihe ndị na-ahụ maka foto na-eme ihe na fotoresist, si otú ahụ na-ebufe ihe nkpuchi ahụ na fotoresist.

Akụrụngwa eji eme ihe maka nhazi na ikpughe bụ igwe fotolithography, nke bụ ihe kachasị ọnụ na otu ngwa usoro nhazi usoro nhazi sekit niile. Ọkwa teknụzụ nke igwe fotolithography na-anọchite anya ọkwa ọganihu nke ahịrị mmepụta dum.

Baking-exposure baking: na-ezo aka na usoro ịsa achịcha dị mkpirikpi mgbe mkpughe gasịrị, nke nwere mmetụta dị iche karịa na fotoresists ultraviolet miri emi na i-line photoresists.

Maka miri emi ultraviolet photoresist, post-exposure baking na-ewepu ihe nchebe na photoresist, na-ekwe ka photoresist na-agbaze na onye mmepụta, ya mere, post-exposure baking dị mkpa;

Maka ndị na-ahụ maka i-line photoresists, ịsa mmiri na-ekpuchi ekpuchi nwere ike ime ka adhesion nke photoresist dịkwuo mma ma belata ebili mmiri na-eguzo (ebili mmiri na-eguzo ga-enwe mmetụta ọjọọ na morphology nsọtụ nke photoresist).

(4)Ịmepụta ihe nkiri siri ike: iji onye nrụpụta igbari akụkụ soluble nke photoresist (photoresist ziri ezi) mgbe ekpughere ya, ma gosipụta nkpuchi nke ọma na ụkpụrụ fotoresist.

The isi parameters nke mmepe usoro na-agụnye mmepe okpomọkụ na oge, onye mmepụta usoro onunu ogwu na itinye uche, ihicha, wdg Site n'ịgbanwe ndị dị mkpa paramita na mmepe, ihe dị iche na mgbasa ọnụego n'etiti ndị na-ekpughe na ndị na-adịghị ekpughe akụkụ nke photoresist nwere ike ịba ụba, si otú ahụ. inweta mmetụta mmepe chọrọ.

Hardening na-mara dị ka hardening mmiri, nke bụ usoro nke na-ewepụ ndị fọdụrụ ihe mgbaze, Mmepụta, mmiri na ndị ọzọ na-adịghị mkpa fọdụrụnụ components na mepụtara photoresist site kpo oku na evaporating ha, nke mere ka mma adhesion nke photoresist na silicon mkpụrụ na. nguzogide etching nke photoresisist.

Okpomọkụ nke usoro siri ike dịgasị iche dabere na fotoresists dị iche iche na ụzọ ndị siri ike. Ebumnuche bụ na ụkpụrụ nke photoresist adịghị emebi emebi na fotoresis kwesịrị ime ka ọ sie ike.

(5)Nyocha mmepe: Nke a bụ ịlele ntụpọ na ụkpụrụ photoresist mgbe mmepe gasịrị. Ọtụtụ mgbe, a na-eji teknụzụ njirimara onyonyo na-enyocha usoro mgbawa ozugbo ka emechara wee jiri ya tụnyere ụkpụrụ ọkọlọtọ na-enweghị ntụpọ echekwara na mbụ. Ọ bụrụ na achọpụtara ihe ọ bụla dị iche, a na-ewere ya dị ka ntụpọ.

Ọ bụrụ na ọnụọgụ ntụpọ karịrị otu uru, a na-ekpebi wafer silicon ka ọ daa ule mmepe ma enwere ike ihichapụ ma ọ bụ rụgharịa ọrụ dịka okwesịrị.

N'ime usoro mmepụta sekit agbakwunyere, ọtụtụ usoro anaghị agbanwe agbanwe, na fotolithography bụ otu n'ime usoro ole na ole enwere ike ịmegharị ya.

Fotomask atọ na ihe ndị na-egbochi ihe

3.1 Foto nkpuchi

Fotomask, nke a makwaara dị ka ihe nkpuchi fotolithography, bụ nna ukwu ejiri na usoro fotolithography nke imepụta wafer sekit jikọtara ọnụ.

Usoro nrụpụta fotomask bụ iji tọghata data okirikiri nhọrọ ukwuu achọrọ maka nrụpụta wafer nke ndị injinia na-emepụta sekit agbakwunyere ka ọ bụrụ usoro data nke ndị na-emepụta ihe na-emepụta laser ma ọ bụ ngwa mkpughe eletrọn nwere ike mata site na nhazi data nkpuchi, ka e wee kpughee ya. ngwá ọrụ dị n'elu na fotomask substrate ihe ejiri ihe na-ese foto; mgbe ahụ, a na-edozi ya site na usoro usoro dị iche iche dị ka mmepe na etching iji dozie ụkpụrụ na ihe nkedo; N'ikpeazụ, a na-enyocha ya, dozie ya, kpochaa, na ihe nkiri na-ekpuchi ya iji mepụta ngwaahịa nkpuchi ma nyefee ya n'aka ndị na-emepụta sekit agbakwunyere maka ojiji.

3.2 Onye na-ese foto

Photoresist, nke a makwaara dị ka photoresist, bụ ihe na-emetụ n'ahụ. Ihe ndị na-ahụ maka foto dị na ya ga-enwe mgbanwe kemịkalụ n'okpuru irradiation nke ìhè, si otú ahụ na-eme ka mgbanwe dị na ọnụego mgbasa. Isi ọrụ ya bụ ịnyefe ụkpụrụ na nkpuchi na mkpụrụ dị ka wafer.

Ụkpụrụ na-arụ ọrụ nke photoresist: Nke mbụ, a na-ekpuchi photoresist na mkpụrụ ahụ ma mee tupu ya ewepụ ihe mgbaze;

Nke abuo, ihe nkpuchi na-ekpughere ìhè, na-eme ka ihe ndị na-ahụ maka foto na-ahụ anya na akụkụ ahụ ekpughere na-enweta mmeghachi omume kemịkalụ;

Mgbe ahụ, a na-eme achịcha na-ekpo ọkụ mgbe e mesịrị;

N'ikpeazụ, a na-agbaze photoresist nke ọma site na mmepe (maka photoresist dị mma, ebe a na-ekpuchi anya na-agbaze; maka fotoresist na-adịghị mma, ebe a na-adịghị ahụ anya na-agbaze), si otú ahụ na-achọpụta nnyefe nke usoro sekit agbakwunyere site na nkpuchi na mkpụrụ.

Akụkụ nke photoresist tumadi gụnyere resin na-akpụ ihe nkiri, akụrụngwa na-ahụ anya, ihe mgbakwunye na ihe mgbaze.

N'ime ha, a na-eji resin na-emepụta ihe nkiri na-enye ihe eji arụ ọrụ na nguzogide etching; akụkụ nke photosensitive na-enweta mgbanwe kemịkalụ n'okpuru ìhè, na-eme mgbanwe na ọnụego mgbasa;

Ihe mgbakwunye trace gụnyere ihe eji esiji, viscosity enhancers, wdg, nke a na-eji emeziwanye arụmọrụ nke photoresist; A na-eji ihe mgbaze eme ihe iji gbazee ihe ndị ahụ ma gwakọta ha nke ọma.

Enwere ike kewaa ndị na-ese foto ugbu a ka ọ bụrụ ndị na-ese foto ọdịnala na ndị na-emepụta ọgwụ kemịkalụ dị ka usoro mmeghachi omume nke photochemical si dị, a pụkwara kewaa ya n'ime ultraviolet, ultraviolet miri emi, ultraviolet dị oke egwu, beam electron, ion beam na X-ray photoresists dị ka nke si kwuo. ogologo oge fotoensitivity.

Ngwa fotolithography anọ

Nkà na ụzụ Photolithography agabigala usoro mmepe nke kọntaktị / ịdị nso lithography, lithography nyocha anya, lithography nzọụkwụ na-emegharị, lithography nyocha, lithography immersion, na lithography EUV.

4.1 Kọntaktị/ Igwe okwu Lithography nso

Teknụzụ lithography kọntaktị pụtara na 1960 ma ejiri ya mee ihe na 1970s. Ọ bụ usoro lithography bụ isi n'oge obere sekit agbakwunyere na nke a na-ejikarị emepụta sekit agbakwunyere nwere nha nha karịa 5μm.

N'igwe kọntaktị / nso nso a, a na-edobe wafer n'ọnọdụ kwụ ọtọ ejiri aka na-achịkwa yana ọrụ na-agbanwe agbanwe. Onye na-arụ ọrụ na-eji microscope ubi pụrụ iche iji lelee ọnọdụ ihe nkpuchi na wafer, ma jiri aka ya na-ejikwa ọnọdụ nke table table iji kwado nkpuchi na wafer. Mgbe wafer na ihe nkpuchi kwadoro, a ga-ejikọta ha abụọ ka ihe mkpuchi ahụ na-ejikọta kpọmkwem na fotoresis n'elu wafer.

Mgbe ewepụchara ebumnobi microscope, wafer na ihe nkpuchi a na-agbanye na-ebugharị na tebụl ikpughe maka ikpughe. Ìhè nke oriọna mercury na-amụnye na-ejikọta ya na ihe nkpuchi ahụ site na oghere. Ebe ọ bụ na ihe nkpuchi ahụ na-akpakọrịta kpọmkwem na oyi akwa photoresist na wafer, a na-ebufe ihe nkpuchi ahụ na oyi akwa photoresist na nha nke 1: 1 mgbe ekpughere ya.

Ngwa kọntaktị lithography bụ ngwa ngwa anya lithography kachasị dị mfe na nke kachasị ọnụ ahịa, yana nwere ike nweta mkpughe nke eserese njiri mara obere micron, yabụ a ka na-eji ya n'ichepụta obere ngwaahịa na nyocha ụlọ nyocha. Na nnukwu mmepụta sekit agbakwunyere, ewebata teknụzụ lithography nso iji zere mmụba nke ọnụ ahịa lithography kpatara site na kọntaktị ozugbo n'etiti ihe nkpuchi na wafer.

A na-eji lithography nso nso na 1970s n'oge oge nke obere sekit agbakwunyere na mmalite oge nke sekit agbakọta ọnụ. N'adịghị ka kọntaktị lithography, ihe nkpuchi na nso lithography adịghị na kọntaktị kpọmkwem na photoresist na wafer, ma a na-ahapụ oghere jupụtara na nitrogen. Ihe nkpuchi na-ese n'elu nitrogen, na nha nke ọdịiche dị n'etiti ihe nkpuchi na wafer na-ekpebi nrụgide nitrogen.

Ebe ọ bụ na ọ dịghị kọntaktị kpọmkwem n'etiti wafer na ihe nkpuchi dị nso na lithography, ntụpọ ndị a na-ebute n'oge usoro lithography na-ebelata, si otú ahụ na-ebelata ihe nkpuchi ma na-emeziwanye mkpụrụ nke wafer. Na lithography dị nso, ọdịiche dị n'etiti wafer na nkpuchi na-etinye wafer na mpaghara Fresnel diffraction. Ọnụnọ nke diffraction na-egbochi mmụba n'ihu nke mkpebi nke akụrụngwa lithography dị nso, yabụ teknụzụ a dabara adaba maka mmepụta nke sekit agbakwunyere na nha nha karịa 3μm.

4.2 Stepper na Repeater

Stepper bụ otu n'ime akụrụngwa kachasị mkpa na akụkọ ihe mere eme nke wafer lithography, nke kwalitere usoro lithography sub-micron n'ime mmepụta oke. The stepper na-eji a-ahụkarị static ubi ikpughe nke 22mm × 22mm na anya ntule anya nwere mbelata ruru 5:1 ma ọ bụ 4:1 nyefee ụkpụrụ na nkpuchi na wafer.

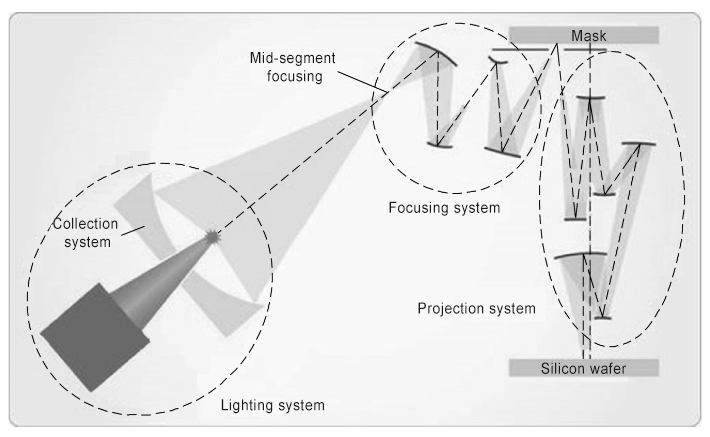

Igwe lithography nke nzọụkwụ na-emegharị n'ozuzu bụ nke subsystem nke mkpughe, sistemu ihe eji arụ ọrụ, usoro ihe nkpuchi ogbo, subsystem na-elekwasị anya / ọkwa, usoro ntinye, sistemụ etiti etiti, subsystem mbufe wafer, subsystem nyefe ihe mkpuchi. , igwe eletrọnịkị, na sistemụ ngwanrọ.

Usoro a na-ahụkarị nke igwe lithography nzọụkwụ na-emegharị bụ nke a:

Nke mbụ, a na-ebufe wafer ahụ na photoresist na tebụl workpiece site na iji usoro mbufe wafer, na ihe mkpuchi a ga-ekpughere na-ebufe ya na tebụl nkpuchi site na iji ihe nkpuchi nnyefe;

Mgbe ahụ, usoro na-eji subsystem na-elekwasị anya / larịị ịrụ multi-point elu nha na wafer na workpiece ogbo nweta ozi dị ka elu na tilt n'akuku nke elu nke wafer na-ekpughe, nke mere na ikpughe ebe nke. Enwere ike ịchịkwa wafer mgbe niile n'ime omimi nke ebumnuche amụma n'oge usoro ikpughe;Mgbe nke ahụ gasịrị, usoro ahụ na-eji usoro nhazi nhazi iji dozie nkpuchi na wafer nke mere na n'oge usoro ikpughe ọnọdụ ziri ezi nke ihe nkpuchi na ihe nfefe wafer na-adị mgbe niile n'ime ihe ndị a chọrọ.

N'ikpeazụ, a na-emecha nzọụkwụ-na mkpughe nke elu wafer dum dị ka ụzọ a tụrụ anya iji ghọta ọrụ nnyefe ụkpụrụ.

Igwe ihe nlebanya na nyocha nke na-esote na-adabere na usoro ọrụ isi dị n'elu, na-eme ka steepụ → ikpughe na nyocha → ikpughe, na ilekwasị anya / ọkwa → ntinye → ikpughe na ihe ngosi nke abụọ na nha (nlekwasị anya / ọkwa → nhazi) na nyocha. ikpughe n'otu aka ahụ.

E jiri ya tụnyere igwe lithography nke nzọụkwụ-na-nyocha, igwe-na-emegharị lithography adịghị mkpa iji nweta nyocha ngbanwe nke nkpuchi na wafer, ọ dịghịkwa achọ tebụl nkpuchi nyocha na sistemụ njikwa nyocha synchronous. Ya mere, ihe owuwu ahụ dị mfe, ọnụ ahịa ya dị ntakịrị, yana ọrụ a pụrụ ịdabere na ya.

Mgbe teknụzụ IC batara 0.25μm, ntinye nke usoro nzọụkwụ na-emegharị lithography malitere ịda n'ihi uru nke usoro-na-nyocha lithography na nyocha nha ubi ikpughe na ịdị n'otu. Ka ọ dị ugbu a, lithography kachasị ọhụrụ na-emegharị na-emegharị nke Nikon na-enye nwere ebe nlele anya static dị ka nke nyocha nke nzọụkwụ na nyocha, ma nwee ike hazie ihe karịrị 200 wafers kwa elekere, yana nrụpụta nrụpụta dị oke elu. Ụdị igwe lithography a na-ejikarị eme ihe maka imepụta akwa IC na-adịghị mkpa.

4.3 Stepper nyocha

Ngwa nke lithography nzọụkwụ na nyocha malitere na 1990s. Site n'ịhazi isi iyi ọkụ dị iche iche, teknụzụ nzọụkwụ na nyocha nwere ike ịkwado ọnụ ụzọ teknụzụ usoro dị iche iche, site na 365nm, 248nm, 193nm imikpu na EUV lithography. N'adịghị ka nzọụkwụ-na-ekpegharị lithography, otu-ubi ikpughe nke nzọụkwụ-na-iṅomi lithography adopts ike ịgụ isiokwu, ya bụ, ihe nkpuchi efere completes na ịgụ isiokwu synchronously ikwu na wafer; mgbe nke ugbu a ubi ikpughe na-agwụ agwụ, na wafer na-ebu site workpiece ogbo na steepụ na-esote scanning ubi ọnọdụ, na ugboro ugboro ikpughe na-aga n'ihu; megharịa mkpughe nzọụkwụ na nyocha ọtụtụ oge ruo mgbe ekpughere mpaghara niile nke wafer ahụ.

Site n'ịhazi ụdị ọkụ dị iche iche (dịka i-line, KrF, ArF), onye nyocha stepper nwere ike ịkwado ihe fọrọ nke nta ka ọ bụrụ ọnụ ọgụgụ teknụzụ niile nke usoro njedebe semiconductor. Usoro CMOS dabere na silicon ejirila stepper-scanners n'ọtụtụ buru ibu kemgbe ọnụ 0.18μm; igwe lithography nke oke ultraviolet (EUV) ejiri ugbu a na ọnụ usoro n'okpuru 7nm na-ejikwa nyocha stepper. Mgbe mgbanwe mgbanwe na-agbanwe agbanwe, onye nyocha stepper nwekwara ike ịkwado nyocha na mmepe na mmepụta nke ọtụtụ usoro na-abụghị silicon dị ka MEMS, ngwaọrụ ike, na ngwaọrụ RF.

Ndị bụ isi na-emepụta igwe onyonyo lithography nzọụkwụ na nyocha gụnyere ASML (Netherland), Nikon (Japan), Canon (Japan) na SMEE (China). ASML weputara TWINSCAN usoro nke usoro nzọụkwụ-na-scan lithography na 2001. Ọ na-anakwere usoro nhazi usoro nke abụọ, nke nwere ike imeziwanye mmepụta nke akụrụngwa nke ọma ma ghọọ igwe lithography kachasị eji eme ihe.

4.4 Immersion Lithography

Enwere ike ịhụ site na usoro Rayleigh na, mgbe ogologo mkpughe na-agbanweghị agbanwe, ụzọ dị irè isi meziwanye mkpebi onyonyo bụ ịbawanye ọnụọgụ ọnụọgụ nke sistemụ onyonyo. Maka mkpebi onyonyo dị n'okpuru 45nm na nke dị elu, usoro ekpughere nkụ nke ArF enweghịzi ike iru ihe achọrọ (n'ihi na ọ na-akwado mkpebi onyonyo kacha elu nke 65nm), yabụ ọ dị mkpa ịmebata usoro lithography imikpu. Na nkà na ụzụ lithography ọdịnala, ihe dị n'etiti oghere na fotoresisist bụ ikuku, ebe teknụzụ lithography nke imikpu mmiri na-eji mmiri mmiri dochie ikuku ikuku (na-abụkarị mmiri ultrapure na ntinye ntinye nke 1.44).

N'ezie, immersion lithography technology na-eji mkpirisi nke wavelength nke ìhè isi iyi mgbe ìhè gafere na mmiri mmiri na-eme ka mkpebi dị mma, na shortening ruru bụ refractive index nke mmiri mmiri ọkara. Ọ bụ ezie na igwe lithography immersion bụ ụdị nke igwe lithography nzọụkwụ-na-enyocha, na usoro akụrụngwa ya agbanwebeghị, ọ bụ mgbanwe na mgbasawanye nke igwe lithography step-na-scan ArF n'ihi iwebata isi teknụzụ metụtara. na-emikpu.

Uru nke lithography immersion bụ na, n'ihi mmụba nke oghere ọnụọgụ nke usoro ahụ, a na-emeziwanye ikike nke foto nke igwe lithography nke stepper-scanner, nke nwere ike imezu ihe ndị chọrọ n'usoro ihe ngosi mkpebi n'okpuru 45nm.

Ebe igwe lithography immersion ka na-eji ọkụ ọkụ ArF, aga n'ihu na usoro a na-ekwe nkwa, na-echekwa ọnụ ahịa R&D nke isi iyi ọkụ, akụrụngwa na usoro. Na ndabere a, jikọtara ya na ọtụtụ eserese na teknụzụ mgbakọ na mwepụ, enwere ike iji igwe lithography immersion na oghere nhazi nke 22nm na n'okpuru. Tupu etinyere igwe lithography EUV n'ihu ọha n'imepụta oke, ejirila igwe lithography immersion mee ihe n'ọtụtụ ebe ma nwee ike mezuo ihe achọrọ nke oghere 7nm. Agbanyeghị, n'ihi iwebata mmiri mmiri imikpu, ihe isi ike injinia nke akụrụngwa n'onwe ya abawanyela nke ukwuu.

Teknụzụ ya ndị bụ isi gụnyere ntinye mmiri mmiri na teknụzụ mgbake, teknụzụ mmezi ubi mmiri mmiri imikpu, mmetọ lithography mmetọ na teknụzụ njikwa ntụpọ, mmepe na mmezi nke oghere imirikiti ọnụọgụ ọnụọgụ, na teknụzụ nchọpụta njirimara n'okpuru ọnọdụ imikpu.

Ka ọ dị ugbu a, ụlọ ọrụ abụọ na-enyekarị igwe ArFi step-na-scan lithography igwe, ya bụ ASML nke Netherlands na Nikon nke Japan. N'ime ha, ọnụahịa nke otu ASML NXT1980 Di bụ ihe dị ka nde euro 80.

4.5 Igwe ihe omimi nke Ultraviolet

Iji mee ka mkpebi nke fotolithography dịkwuo mma, a na-emeziwanye ogologo oge ikpughe mgbe a nakweere isi iyi ọkụ excimer, na ọkụ ultraviolet dị oke na ogologo nke 10 ruo 14 nm na-ewebata dị ka ìhè ikpughe. Ogologo ebili mmiri nke oke ọkụ ultraviolet dị oke mkpụmkpụ, na usoro ihe anya na-egosipụta nke enwere ike iji mee ihe na-abụkarị ihe ngosi ihe nkiri multilayer dị ka Mo/Si ma ọ bụ Mo/Be.

N'ime ha, usoro ihe ngosi kachasị nke Mo / Si multilayer film na ogologo ogologo nke 13.0 ruo 13.5nm bụ ihe dịka 70%, na ihe ngosi kachasị nke Mo / Be multilayer film na obere wavelength nke 11.1nm bụ ihe dịka 80%. Ọ bụ ezie na nlegharị anya nke Mo/Be multilayer film reflectors dị elu, Be na-egbu egbu nke ukwuu, n'ihi ya, a gbahapụrụ nyocha banyere ihe ndị dị otú ahụ mgbe ọ na-emepụta teknụzụ lithography EUV.Teknụzụ lithography EUV dị ugbu a na-eji ihe nkiri multilayer Mo/Si, na ogologo mkpughe ya na-ekpebikwa ịbụ 13.5nm.

Isi iyi ọkụ ultraviolet dị oke egwu na-eji teknụzụ plasma emepụtara laser (LPP), nke na-eji lasers ike dị elu iji kpalie Sn plasma na-ekpo ọkụ na-ebunye ọkụ. Ruo ogologo oge, ike na nnweta nke ìhè ọkụ bụ ihe mgbochi na-egbochi ịrụ ọrụ nke igwe lithography EUV. Site na igwe oscillator ike amplifier, teknụzụ amụma amụma plasma (PP) na teknụzụ nhicha enyo enyo, ike na nkwụsi ike nke isi iyi ọkụ EUV emeela nke ọma.

Igwe lithography EUV bụ nke mejupụtara sistemụ subsystem dị ka isi iyi ọkụ, ọkụ, oghere ebumnuche, ogbo workpiece, ogbo nkpuchi, nhazi wafer, itinye uche / ọkwa, nnyefe nkpuchi, nnyefe wafer, na oghere oghere. Mgbe ị gafechara usoro ihe ọkụ nke mejupụtara ihe mkpuchi mkpuchi mkpuchi multi-layer, ọkụ ultraviolet dị oke ọkụ na-enwu na nkpuchi na-egosipụta. Ìhè na-egosipụta site na nkpuchi na-abanye n'ime usoro ihe nlegharị anya anya zuru oke nke mejupụtara usoro ihe nkpuchi, na n'ikpeazụ, a na-egosipụta onyinyo nke ihe nkpuchi ahụ n'elu wafer na ebe oghere.

Oghere mkpughe na ebe onyonyo nke igwe lithography EUV bụ ụdị arc abụọ, a na-eji usoro nyocha nke nzọụkwụ iji nweta mkpughe wafer zuru oke iji melite ọnụego mmepụta. Usoro NXE nke ASML kachasị elu nke EUV lithography igwe na-eji isi iyi ọkụ mkpughe nwere ogologo 13.5nm, ihe nkpuchi na-atụgharị anya (6° oblique incidence), 4x mbelata ihe nleba anya n'usoro ebumnuche nwere nhazi 6-mirror (NA=0.33), a oghere nyocha nke 26mm × 33mm, yana ebe mkpughe agụụ.

E jiri ya tụnyere igwe lithography immersion, otu mkpebi mkpughe nke igwe igwe lithography EUV na-eji oke ọkụ ultraviolet ka emelitere nke ọma, nke nwere ike zere nke ọma usoro mgbagwoju anya achọrọ maka otutu fotolithography iji mepụta eserese dị elu. Ka ọ dị ugbu a, otu mkpebi mkpughe nke igwe lithography NXE 3400B nwere oghere ọnụọgụ nke 0.33 ruru 13nm, ọnụego mmepụta ruru 125 iberibe / h.

Iji gboo mkpa nke ndọtịkwu nke Iwu Moore, n'ọdịniihu, igwe igwe lithography EUV nwere oghere ọnụọgụ nke 0.5 ga-enweta usoro ebumnuche amụma na mgbochi ọkụ etiti, na-eji mmụba asymmetric nke ugboro 0.25 / 0.125, yana A ga-ebelata oghere nlele nyocha site na 26m × 33mm ruo 26mm × 16.5mm, na otu mkpebi mkpughe nwere ike. iru n'okpuru 8nm.

———————————————————————————————————————————————————————— ———————————

Semicera nwere ike inyeakụkụ graphite, mmetụta dị nro / siri ike, akụkụ silicon carbide, Akụkụ CVD silicon carbide, naAkụkụ SiC/TaC mkpuchina usoro semiconductor zuru oke n'ime ụbọchị 30.

Ọ bụrụ na ị nwere mmasị na ngwaahịa semiconductor ndị a,biko egbula oge ịkpọtụrụ anyị na oge mbụ.

Tel: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Oge nzipu: Ọgọst-31-2024