Otu Okwu Mmalite

E kewara etching na usoro nrụpụta sekit agbakwunyere n'ime:

- Mmiri etching;

-Akọrọ etching.

N'oge mbụ, a na-eji mmiri etching eme ihe n'ọtụtụ ebe, mana n'ihi njedebe ya na njikwa obosara ahịrị na ntụziaka etching, ọtụtụ usoro mgbe 3μm na-eji etching akọrọ. A na-eji etching mmiri naanị wepụ ụfọdụ akwa akwa pụrụ iche na ihe ndị dị ọcha.

Etching akọrọ na-ezo aka na usoro iji etchants kemịkalụ gaseous meghachi omume na ihe ndị dị na wafer iji wepụ akụkụ nke ihe a ga-ewepụ ma mepụta ngwaahịa mmeghachi omume na-agbanwe agbanwe, nke a na-esi na ụlọ mmeghachi omume pụta. A na-emepụta Etchant ozugbo ma ọ bụ na-apụtaghị ìhè site na plasma nke etching gas, ya mere a na-akpọkwa etching akọrọ na plasma etching.

1.1 Plasma

Plasma bụ gas na steeti ion na-esighi ike nke etolite site na mwepu nke na-egbuke egbuke nke na-acha ọkụ n'okpuru ọrụ nke ikuku electromagnetic dị na mpụga (dị ka ọkụ ọkụ redio na-ebute). Ọ na-agụnye electrons, ion na ndị na-anọpụ iche na-arụ ọrụ. N'ime ha, ụmụ irighiri ihe na-arụ ọrụ nwere ike meghachi omume ozugbo na ihe etched iji nweta etching, mana mmeghachi omume kemịkalụ a dị ọcha na-emekarị naanị n'ọnụ ọgụgụ dị nta nke ihe na ọ bụghị ntụziaka; mgbe ion nwere ụfọdụ ume, ha nwere ike etched site kpọmkwem anụ ahụ sputtering, ma etching ọnụego nke a dị ọcha mmeghachi omume anụ ahụ dị nnọọ ala na selectivity dị nnọọ ogbenye.

A na-emecha ọtụtụ etching plasma site na ntinye aka nke ụmụ irighiri ihe na ion na-arụ ọrụ n'otu oge. Na usoro a, ion bombardment nwere ọrụ abụọ. Otu bụ ibibi agbụ atọm n'elu ihe etched, si otú ahụ na-abawanye ọnụego nke ihe ndị na-anọpụ iche na-emeghachi omume na ya; nke ọzọ bụ ịkụtu ngwaahịa mmeghachi omume na-edobe na interface mmeghachi omume iji mee ka enchant ahụ zuru ezu kpọtụrụ elu nke ihe etched, nke mere na etching na-aga n'ihu.

Ngwaahịa mmeghachi omume na-edobere n'akụkụ akụkụ nke ihe owuwu etched enweghị ike iwepụ nke ọma site na bọmbụ ion ntụzịaka, si otú a na-egbochi etching nke akụkụ akụkụ ma na-akpụ etching anisotropic.

Usoro etching nke abụọ

2.1 Wet Etching na ihicha

Wet etching bụ otu n'ime teknụzụ izizi ejiri na nrụpụta sekit agbakwunyere. Ọ bụ ezie na a na-eji anisotropic akọrọ etching dochie ọtụtụ usoro mmiri mmiri mmiri n'ihi etching isotropic ya, ọ ka na-arụ ọrụ dị mkpa n'ịsacha ọkwa ndị na-adịghị mkpa nke nnukwu nha. Karịsịa na etching nke mkpochapụ oxide na mkpochapụ epidermal, ọ dị irè ma dị irè karịa etching akọrọ.

Ihe etching mmiri na-agụnyekarị silicon oxide, silicon nitride, silicon crystal silicon na silicon polycrystalline. Wet etching nke silicon oxide na-ejikarị hydrofluoric acid (HF) dị ka isi ihe na-ebu kemịkal. Iji meziwanye selectivity, a na-eji dilute hydrofluoric acid buffered site ammonium fluoride na usoro. Iji nọgide na-enwe nkwụsi ike nke uru pH, enwere ike ịgbakwunye obere acid siri ike ma ọ bụ ihe ndị ọzọ. Silikoni oxide doped na-adị mfe imebi karịa silicon oxide dị ọcha. A na-ejikarị ịwepụ kemịkalụ mmiri mmiri wepụ fotoresisist na nkpuchi siri ike (silicon nitride). Acid phosphoric na-ekpo ọkụ (H3PO4) bụ mmiri mmiri kemịkalụ bụ isi nke a na-eji maka ịwepu kemịkalụ mmiri wepụrụ silicon nitride, ma nwee ezigbo nhọrọ maka silicon oxide.

Nhicha mmiri dị ka etching mmiri, na-ewepụkwa ihe ndị na-emerụ emerụ n'elu ihe ndị na-emepụta silicon site na mmeghachi omume kemịkalụ, gụnyere ụmụ irighiri ihe, organic okwu, ọla na oxides. Nhicha mmiri bụ isi bụ usoro kemịkalụ mmiri. Ọ bụ ezie na ihicha akọrọ nwere ike dochie ọtụtụ ụzọ nhicha mmiri mmiri, ọ dịghị usoro nwere ike dochie kpamkpam nhicha mmiri.

Kemịkalụ a na-ejikarị eme ihe maka nhicha mmiri gụnyere sulfuric acid, hydrochloric acid, hydrofluoric acid, phosphoric acid, hydrogen peroxide, ammonium hydroxide, ammonium fluoride, wdg N'ime ngwa bara uru, a na-agwakọta otu ma ọ bụ karịa kemịkalụ na mmiri deionized n'otu akụkụ dịka ọ dị mkpa. mepụta ngwọta nhicha, dị ka SC1, SC2, DHF, BHF, wdg.

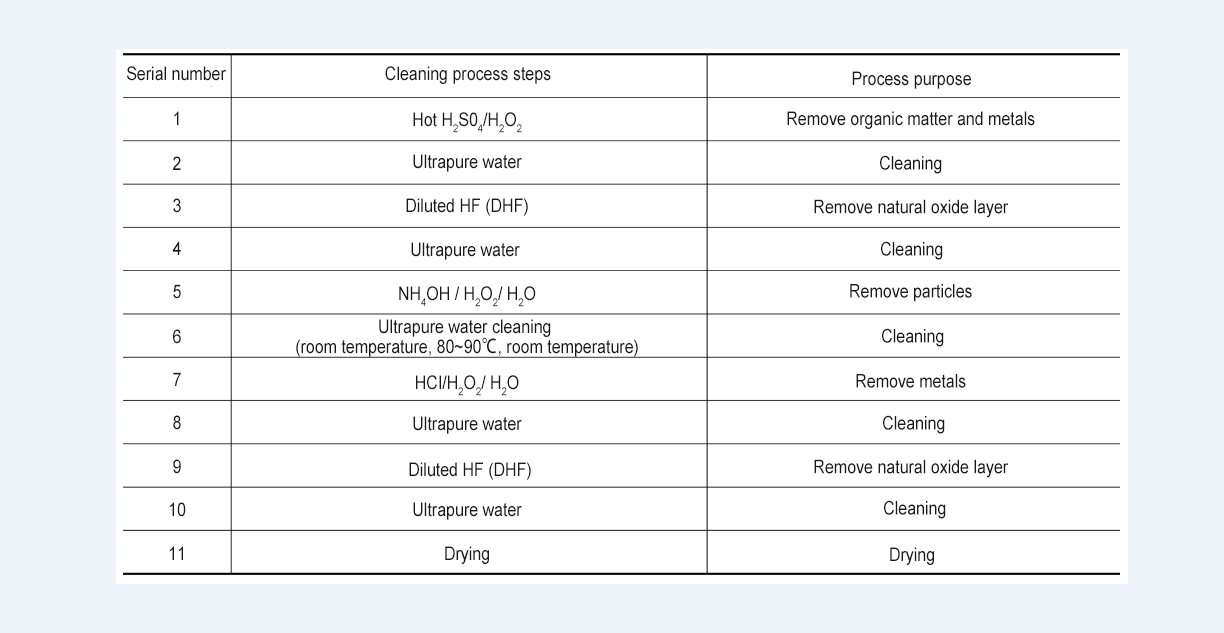

A na-ejikarị ihicha ihe na usoro ahụ tupu ntinye ihe nkiri oxide, n'ihi na a ghaghị ime nkwadebe nke ihe nkiri oxide n'elu ihe mkpuchi silicon dị ọcha. Usoro ihicha silicon wafer bụ nke a:

2.2 Etching na ihicha

2.2.1 Etching akọrọ

Akọrọ akọrọ na ụlọ ọrụ na-ezo aka na plasma etching, nke na-eji plasma nwere nkwalite ọrụ iji chịkọta ihe ụfọdụ. Usoro akụrụngwa na usoro mmepụta ihe dị ukwuu na-eji plasma dị ala na-abụghị nke nha.

Plasma etching na-ejikarị ụdị mwepu abụọ: capacitive jikọtara mwepu na inductive jikọtara mmịpụta

N'ụdị mwepu ike jikọtara ọnụ: plasma na-emepụta ma na-edobe ya na capacitors efere abụọ yiri ya site na ọkụ ikuku redio mpụga (RF). Nrụgide gas na-abụkarị ọtụtụ millitorr ruo iri iri nke millitorr, na ọnụego ionization na-erughị 10-5. N'ụdị mwepu nke jikọtara ọnụ: n'ozuzu na nrụgide gas dị ala (iri iri millitorr), a na-emepụta plasma ma na-echekwa ya site na ntinye ike jikọtara ọnụ. Ọnụọgụ ionization na-adịkarị karịa 10-5, yabụ a na-akpọkwa ya plasma dị elu. Enwere ike nweta isi mmalite plasma dị elu site na resonance eletrọn cyclotron na mwepu ebili mmiri cyclotron. Plasma dị elu nwere ike ịkwalite ọnụego etching na nhọrọ nke usoro etching ka ọ na-ebelata mmebi etching site n'ịchịkwa oke ion na ike bombu ion site na mpụta RF ma ọ bụ ngwa ndakwa nri na ọkụ ọkụ RF na mkpụrụ.

Usoro etching akọrọ bụ nke a: a na-agbanye gas etching n'ime ụlọ mmeghachi omume na-ekpo ọkụ, na mgbe nrụgide dị n'ime ụlọ mmeghachi omume kwadoro, a na-emepụta plasma site na mgbapụta ọkụ ọkụ redio; mgbe electrons na-agba ọsọ na-emetụta ya, ọ na-emepụta ihe na-emepụta free radicals, nke na-agbasa n'elu nke mkpụrụ ahụ ma na-agbanye ya. N'okpuru ọrụ nke ion bombardment, adsorbed free radicals na-emeghachi omume na atọm ma ọ bụ ụmụ irighiri ihe dị n'elu nke mkpụrụ na-emepụta gaseous byproducts, nke a na-ahapụ na mmeghachi omume ụlọ. E gosipụtara usoro a na foto a:

Enwere ike ikewa usoro etching akọrọ n'ụdị anọ ndị a:

(1)Etching anụ ahụ: Ọ na-adabere na ion ume dị na plasma iji tụọ elu ihe etched. Ọnụọgụ nke atọm agbasa na-adabere na ike na akụkụ nke irighiri ihe merenụ. Mgbe ike na akụkụ adịghị agbanwe agbanwe, ọnụọgụ sputtering nke ihe dị iche iche na-adịkarị iche site na naanị 2 ruo 3 ugboro, ya mere ọ dịghị selectivity. Usoro mmeghachi omume na-abụkarị anisotropic.

(2)Chemical etching: Plasma na-enye gas-phase etching atom na ụmụ irighiri ihe, nke na-emeghachi omume na kemịkalụ n'elu ihe na-emepụta gas na-agbanwe agbanwe. Mmeghachi omume kemịkalụ a dị naanị nwere ezigbo nhọrọ ma gosipụta njirimara isotropic na-atụleghị usoro lattice.

Dịka ọmụmaatụ: Si (si ike) + 4F → SiF4 (gaseous), photoresist + O (gaseous) → CO2 (gaseous) + H2O (gaseous)

(3)Ion ike chụpụrụ etching: Ions bụ ma ahụ na-eme ka etching na ike na-ebu. Ịrụ ọrụ dị otú ahụ na-ebu ume dị elu karịa nke etching anụ ahụ ma ọ bụ kemịkal dị mfe. N'ime ha, njikarịcha nke anụ ahụ na nke kemịkal nke usoro ahụ bụ isi nke ịchịkwa usoro etching.

(4)Ion-ihe mgbochi mejupụtara etching: Ọ tumadi na-ezo aka na ọgbọ nke a polymer mgbochi oyi akwa echebe ahụ mejupụtara n'oge etching usoro. Plasma chọrọ mkpuchi nchebe dị otú ahụ iji gbochie mmeghachi omume etching nke akụkụ akụkụ n'oge usoro etching. Dịka ọmụmaatụ, ịgbakwụnye C na Cl na Cl2 etching nwere ike ịmepụta oyi akwa chlorocarbon n'oge etching iji chebe akụkụ akụkụ ka ọ ghara ịcha.

2.2.1 Nhicha akọrọ

Nhicha akọrọ na-ezo aka na ihicha plasma. A na-eji ion na plasma na-atụ bọmbụ n'elu ka a na-ehicha ya, na atom na ụmụ irighiri ihe dị na steeti a na-arụ ọrụ na-emekọ ihe n'elu ka a na-ehicha ya, ka e wee wepụ na ntụ nke photoresist. N'adịghị ka akọrọ etching, usoro parameters nke akọrọ ihicha na-emekarị anaghị agụnye directional selectivity, otú usoro imewe dị dịtụ mfe. N'ime usoro mmepụta buru ibu, a na-ejikarị fluorine gas, oxygen ma ọ bụ hydrogen mee ihe dị ka akụkụ bụ isi nke plasma mmeghachi omume. Tụkwasị na nke ahụ, ịgbakwunye ụfọdụ plasma argon nwere ike ime ka mmetụta bombardment ion dịkwuo mma, si otú ahụ na-eme ka nhicha dị ọcha.

N'ime usoro ihicha akọrọ na plasma, a na-ejikarị usoro plasma dịpụrụ adịpụ eme ihe. Nke a bụ n'ihi na n'ime usoro nhicha ahụ, a na-atụ anya na ọ ga-ebelata mmetụta bombu nke ions na plasma iji chịkwaa mmebi nke ion bombardment kpatara; na nkwalite mmeghachi omume nke kemịkalụ free radicals nwere ike melite arụmọrụ ihicha. Plasma dịpụrụ adịpụ nwere ike iji microwaves mepụta plasma kwụsiri ike na nke dị elu n'èzí ụlọ mmeghachi omume, na-emepụta ọnụ ọgụgụ dị ukwuu nke free radicals na-abanye n'ime ụlọ mmeghachi omume iji nweta mmeghachi omume achọrọ maka nhicha. Ọtụtụ n'ime isi mmalite gas na-ehicha nkụ na ụlọ ọrụ na-eji gas sitere na fluorine, dị ka NF3, na ihe karịrị 99% nke NF3 na-emebi na plasma microwave. Ọ fọrọ nke nta ka ọ bụrụ na ọ dịghị mmetụta bombardment ion na usoro ikpocha akọrọ, ya mere ọ bara uru iji chebe silicon wafer site na mmebi ma gbasaa ndụ nke ụlọ mmeghachi omume.

Atọ mmiri etching na ihicha akụrụngwa

3.1 Tank-ụdị wafer ihicha igwe

Igwe na-ehicha akwa nke ụdị wafer na-abụkarị nke a na-ebufe igbe mbufe wafer na-emeghe n'ihu, modul nnyefe / nbudata wafer, modul ikuku ikuku, modul mmiri mmiri kemịkalụ, modul mmiri mmiri deionized, tankị ihicha. modul na modul njikwa. Ọ nwere ike ihicha ọtụtụ igbe nke wafers n'otu oge ma nwee ike nweta nkụ-na na nkụ nke wafers.

3.2 Trench Wafer Etcher

3.3 Otu ngwa nhazi mmiri mmiri wafer

Dị ka usoro dị iche iche nzube, otu wafer mmiri usoro akụrụngwa nwere ike kewaa atọ edemede. Ụdị nke mbụ bụ otu ihe na-ehicha otu wafer, onye ebumnuche ihicha ya gụnyere ụmụ irighiri ihe, ihe ndị dị ndụ, oyi akwa oxide eke, adịghị ọcha ígwè na ihe ndị ọzọ na-emerụ emerụ; Udi nke abuo bu otu ihe eji eme ihe na-ekpochapu ihe, onye isi ihe bu n'uche bu iwepu ihe ndi ozo n'elu wafer; Ụdị nke atọ bụ ngwá ọrụ etching nke otu wafer, nke a na-ejikarị ewepụ ihe nkiri ndị dị mkpa. Dabere na ebumnuche usoro dị iche iche, enwere ike kewaa akụrụngwa etching otu wafer na ụdị abụọ. Ụdị nke mbụ bụ ngwá ọrụ etching dị nro, nke a na-ejikarị ewepụ ihe nkiri ihe nkiri dị n'elu nke sitere na ntinye ion ike dị elu; Ụdị nke abụọ bụ ihe eji ewepu oyi akwa ịchụ àjà, nke a na-ejikarị ewepụ ihe mgbochi n'ígwé mgbe wafer thinning ma ọ bụ chemical n'ibu polishing.

Site n'echiche nke n'ozuzu igwe ije, isi ije nke ụdị nile nke otu-wafer mmiri usoro akụrụngwa yiri, n'ozuzu mejupụtara isii akụkụ: isi etiti, wafer nyefe usoro, ụlọ modul, chemical mmiri mmiri ọkọnọ na nyefe modul, software usoro. na modul akara eletrọnịkị.

3.4 Ngwa nhicha otu Wafer

Emebere otu ihe eji ihicha otu wafer dabere na usoro ihicha omenala RCA, na ebumnuche ya bụ ka ihicha irighiri ihe, ihe organic, oyi akwa oxide eke, adịghị ọcha ọla na ihe ndị ọzọ na-emerụ emerụ. N'ihe gbasara ngwa usoro, a na-eji ngwa nhicha otu wafer dị ugbu a na njedebe n'ihu na azụ azụ nke usoro mmepụta sekit agbakwunyere, gụnyere ihicha tupu na mgbe emechara ihe nkiri, ihicha plasma etching, ihicha mgbe ntinye ion, ihicha kemịkalụ. n'ibu polishing, na ihicha mgbe nke metal deposition. Ewezuga usoro phosphoric acid dị elu, akụrụngwa nhicha otu wafer dabara na usoro nhicha niile.

3.5 Ngwa Etching Wafer Single

Nzube usoro nke otu wafer etching akụrụngwa bụ tumadi mkpa film etching. Dị ka usoro nzube, ọ nwere ike kewara abụọ edemede, ya bụ, ìhè etching ngwá (eji na-ewepụ elu film mmebi oyi akwa kpatara elu-ike ion implantation) na àjà oyi akwa mwepụ ngwá (eji wepụ ihe mgbochi oyi akwa mgbe wafer). thinning ma ọ bụ kemịkalụ n'ibu polishing). Ihe ndị a ga-ewepụ na usoro a n'ozuzu gụnyere silicon, silicon oxide, silicon nitride na metal film layers.

Akọrọ etching na ihicha akụrụngwa anọ

4.1 Nhazi nke akụrụngwa etching plasma

Na mgbakwunye na ion sputtering etching akụrụngwa nke dị nso na mmeghachi omume anụ ahụ dị ọcha na ngwa mbelata nke dị nso na mmeghachi omume kemịkalụ dị ọcha, enwere ike kewaa plasma etching n'ụzọ abụọ dịka ọgbọ plasma dị iche iche na teknụzụ njikwa:

-Akụkọ Plasma (CCP) etching;

-Etching Plasma (ICP) na-arụkọ ọrụ ọnụ.

4.1.1 CCP

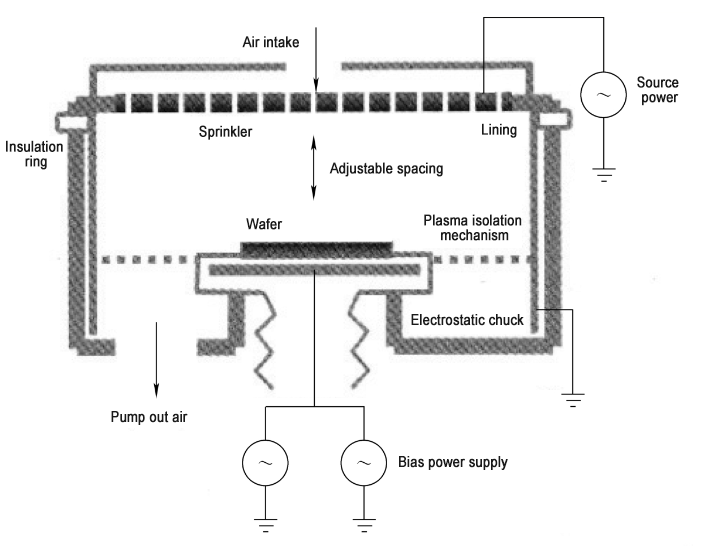

Ngwakọta plasma etching capacitively jikọtara ọnụ bụ ijikọ ọkụ ugboro redio na otu ma ọ bụ abụọ nke elu na nke ala electrodes n'ime ụlọ mmeghachi omume, na plasma n'etiti efere abụọ ahụ na-etolite capacitor na sekit dị mfe nhata.

Enwere teknụzụ abụọ mbụ dị otú ahụ:

Otu bụ etching plasma nke mbụ, nke na-ejikọta ike RF na electrode dị elu na electrode nke ala ebe wafer dị na-agbanye ala. N'ihi na plasma emepụtara n'ụzọ dị otú a agaghị etolite n'ọbọ ion zuru oke n'elu wafer, ike nke bombu ion dị ala, a na-ejikarị ya eme ihe na usoro dị ka silicon etching nke na-eji ihe ndị na-arụ ọrụ dị ka isi ihe.

Nke ọzọ bụ mmalite reactive ion etching (RIE), nke na-ejikọta ike RF na electrode ala ebe wafer dị, na-agbanyekwa electrode elu na mpaghara buru ibu. Nkà na ụzụ a nwere ike ịmepụta n'ọbọ ion dị arọ, nke kwesịrị ekwesị maka usoro etching dielectric nke chọrọ ike ion dị elu iji sonye na mmeghachi omume. Dabere na mmeghachi omume ion etching n'oge, a na-agbakwunye oghere magnetik DC na mpaghara eletriki RF ka ọ bụrụ mkpagharị ExB, nke nwere ike ịbawanye ohere nkukota nke elektrọn na ụmụ irighiri gas, si otú a na-emeziwanye mkpokọta plasma na ọnụego etching nke ọma. A na-akpọ etching a magnetik field enhanced reactive ion etching (MERIE).

Teknụzụ atọ ndị dị n'elu nwere ihe ọghọm, ya bụ, enweghị ike ịchịkwa mkpokọta plasma na ike ya iche. Dịka ọmụmaatụ, iji mee ka ọnụ ọgụgụ etching dị elu, usoro nke ịba ụba ike RF nwere ike iji mee ka ntinye uche na plasma dịkwuo elu, ma ike RF na-abawanye ga-eduga n'ịbawanye ike ion, nke ga-emebi ngwaọrụ ndị dị na ya. nke wafer. N'ime afọ iri gara aga, teknụzụ njikọta capacitive anabatala nhazi nke ọtụtụ isi mmalite RF, nke ejikọrọ na electrodes nke elu na nke ala n'otu n'otu ma ọ bụ ha abụọ na electrode dị ala.

Site n'ịhọrọ na dakọtara ugboro ugboro RF dị iche iche, mpaghara electrode, oghere, ihe na ihe ndị ọzọ dị mkpa na-ejikọta ibe ha, a na-ejikọta mkpokọta plasma na ike ion dị ka o kwere mee.

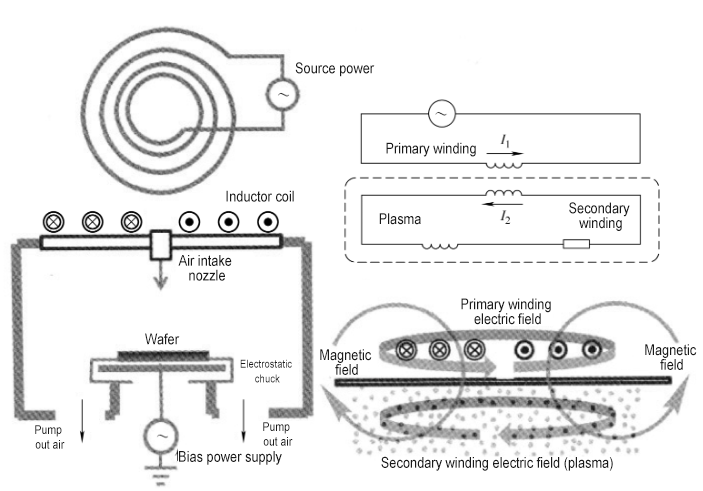

4.1.2 ICP

Etching plasma jikọtara nke ọma bụ idowe otu igwe ma ọ bụ karịa nke ejikọrọ na ọkụ ugboro redio na ma ọ bụ n'akụkụ ọnụ ụlọ mmeghachi omume. Ebe ndọta ọzọ na-emepụta site na ugboro redio dị ugbu a na eriri igwe na-abanye n'ọnụ ụlọ mmeghachi omume site na windo dielectric iji mee ka electrons dịkwuo elu, si otú ahụ na-emepụta plasma. Na sekit dị mfe nhata (transformer), eriri igwe bụ isi ikuku inductance, na plasma bụ inductance nke abụọ.

Usoro njikọ a nwere ike nweta ntinye uche nke plasma nke karịrị otu usoro nke ịdị elu karịa njikọta capacitive na nrụgide dị ala. Tụkwasị na nke ahụ, a na-ejikọta ọkụ ọkụ RF nke abụọ na ọnọdụ nke wafer dị ka ike na-adịghị mma iji nye ike bombardment ion. Ya mere, ntinye uche nke ion na-adabere na isi iyi ike nke eriri igwe na ike ion na-adabere na ike ọkụ na-adịghị mma, si otú ahụ na-enweta nhazi nke ọma nke itinye uche na ume.

4.2 Ngwa Plasma Etching

Ihe fọrọ nke nta ka ọ bụrụ etchants niile dị na etching akọrọ na-esite na plasma ozugbo ma ọ bụ na-apụtaghị ìhè, ya mere a na-akpọkarị etching akọrọ. Plasma etching bụ ụdị etching plasma n'ụzọ sara mbara. N'ime atụmatụ reactor abụọ nke mbụ dị larịị, otu bụ ịkwatu efere ebe wafer dị na nke ọzọ jikọtara ya na isi iyi RF; nke ọzọ bụ iche. N'ime nhazi mbụ, mpaghara nke efere ala na-abụkarị ibu karịa ebe nke efere ejikọrọ na isi iyi RF, na nrụgide gas dị na reactor dị elu. Ọbọ ion nke a na-eme n'elu wafer dị ezigbo mkpa, na wafer ahụ yiri ka ọ "na-emikpu" na plasma. A na-emecha etching nke ọma site na mmeghachi omume kemịkalụ dị n'etiti ụmụ irighiri ihe na-arụ ọrụ na plasma na elu ihe etched. Ike nke bombu ion dị ntakịrị, na ntinye aka na etching dị ntakịrị. A na-akpọ imewe a ọnọdụ etching plasma. N'ime imewe ọzọ, n'ihi na ogo nsonye nke bombu ion dị ntakịrị, a na-akpọ ya reactive ion etching mode.

4.3 Ngwa Ion Etching Reactive

Ion etching reactive (RIE) na-ezo aka na usoro etching nke ụmụ irighiri ihe na-arụ ọrụ na ion ebubo na-esonye na usoro ahụ n'otu oge. N'ime ha, ihe ndị na-arụsi ọrụ ike bụ ndị na-anọpụ iche (nke a makwaara dị ka free radicals), na-enwe nnukwu ntinye (ihe dị ka 1% ruo 10% nke ntinye gas), nke bụ isi ihe dị na echant. Ngwaahịa a na-emepụta site na mmeghachi omume kemịkalụ n'etiti ha na ihe etched na-agbanwe ma na-ewepụta ya ozugbo site na ụlọ mmeghachi omume, ma ọ bụ na-akwakọba n'elu etched; ebe ion ebubo na-adị na ntinye uche dị ala (10-4 ruo 10-3 nke ikuku gas), na ha na-eme ka ọkụ eletrik nke ion sheath na-emepụta n'elu nke wafer ka bombard n'elu etched. Enwere isi ọrụ abụọ nke ihe ebubo ebubo. Otu bụ ibibi atomiki Ọdịdị nke etched ihe onwunwe, si otú accelerating ọnụego na nke nọ n'ọrụ irighiri meghachi omume na ya; nke ọzọ bụ ịtụ bọmbụ ma wepụ ngwaahịa mmeghachi omume na-akwakọba ka ihe etched wee na-enwe mmekọrịta zuru oke na ihe ndị na-arụ ọrụ, nke mere na etching na-aga n'ihu.

N'ihi na ion adịghị esonye kpọmkwem na mmeghachi omume etching (ma ọ bụ na-aza ajụjụ maka ntakịrị ntakịrị, dị ka mwepu bọmbụ anụ ahụ na etching chemical etching nke ion nọ n'ọrụ), n'ikwu ya n'ụzọ doro anya, usoro etching dị n'elu kwesịrị ịkpọ ion-enyere etching aka. Aha reactive ion etching ezighi ezi, mana a ka na-eji ya taa. Ejiri ngwa RIE mbụ rụọ ọrụ na 1980s. N'ihi iji otu ọkụ ọkụ RF na nhazi ụlọ mmeghachi omume dị mfe, ọ nwere oke n'ihe gbasara ọnụego etching, ịdị n'otu na nhọrọ.

4.4 Ngwa Igwe Ọdụdọ Igwe Ọdụdọ emelitere Reactive ion Etching Equipment

Ngwa MERIE (Magnetically Enhanced Reactive Ion Etching) bụ ngwaọrụ etching nke arụpụtara site n'ịgbakwunye oghere magnetik DC na ngwaọrụ RIE dị larịị ma e bu n'obi ịbawanye ọnụego etching.

Ejiri ngwá ọrụ MERIE mee ihe n'ọ̀tụ̀tụ̀ dị ukwuu n'afọ ndị 1990, mgbe ngwá ọrụ etching nke otu wafer aghọwo ihe bụ́ isi na ụlọ ọrụ ahụ. Ihe ọghọm kachasị dị na akụrụngwa MERIE bụ na inhomogeneity nkesa nkesa nke itinye uche na plasma na-akpata ga-eduga n'iche dị ugbu a ma ọ bụ voltaji na ngwaọrụ sekit agbakwunyere, si otú a na-emebi ngwaọrụ. Ebe ọ bụ na mmebi a na-akpata site na inhomogeneity ozugbo, ntụgharị nke oghere magnet enweghị ike iwepụ ya. Ka nha nke sekit agbakwunyere na-aga n'ihu na-ebelata, mmebi ngwaọrụ ha na-enwewanye mmetụta maka inhomogeneity plasma, yana teknụzụ nke ịbawanye ọnụ ọgụgụ etching site na ịkwalite oghere magnet ejirila teknụzụ multi-RF na-enye ike na-emeghachi omume ion etching were dochie ya. bụ teknụzụ etching plasma nwere ike jikọtara ọnụ.

4.5 akụrụngwa etching plasma nwere ike jikọtara ọnụ

Ngwa etching plasma capacitively jikọtara ọnụ (CCP) bụ ngwaọrụ na-emepụta plasma n'ime ụlọ mmeghachi omume site na njikọta capacitive site n'itinye ike redio (ma ọ bụ DC) na efere electrode ma jiri ya mee ihe. Ụkpụrụ etching ya yiri nke akụrụngwa ion etching reactive.

E gosipụtara eserese schematic dị mfe nke akụrụngwa etching CCP n'okpuru. Ọ na-ejikarị isi mmalite RF abụọ ma ọ bụ atọ nke ugboro dị iche iche, ụfọdụ na-ejikwa ọkụ DC. Ugboro nke ọkụ ọkụ RF bụ 800kHz~162MHz, ndị a na-ejikarị eme ihe bụ 2MHz, 4MHz, 13MHz, 27MHz, 40MHz na 60MHz. A na-akpọkarị inye ọkụ RF nwere ugboro 2MHz ma ọ bụ 4MHz isi mmalite RF dị ala. Ha na-ejikọtakarị na electrode ala ebe wafer dị. Ha na-arụ ọrụ nke ọma n'ịchịkwa ike ion, ya mere a na-akpọkwa ha ọkụ eletrik; Ike RF nwere ugboro karịa 27MHz ka a na-akpọ isi mmalite RF dị elu. Enwere ike ijikọ ha na electrode elu ma ọ bụ electrode nke ala. Ha na-arụ ọrụ nke ọma n'ịchịkwa itinye uche na plasma, ya mere a na-akpọkwa ha isi iyi ike. Ọkụ ọkụ 13MHz RF dị n'etiti ma a na-echekarị na ọ nwere ọrụ abụọ a dị n'elu mana ọ na-esiwanye ike. Rịba ama na ọ bụ ezie na enwere ike ịhazigharị ntinye uche na ike plasma n'ime oke ụfọdụ site na ike nke isi mmalite RF nke ugboro dị iche iche (nke a na-akpọ mmetụta nkwụsịtụ), n'ihi njirimara nke njikọta capacitive, enweghị ike ịhazi ma chịkwaa ha kpamkpam.

Ike nkesa nke ion nwere mmetụta dị ịrịba ama na arụmọrụ zuru ezu nke etching na mmebi ngwaọrụ, ya mere, mmepe nke nkà na ụzụ iji kwalite nkesa ike ion aghọwo otu n'ime isi ihe nke ngwá ọrụ etching dị elu. Ugbu a, teknụzụ ejirila nke ọma na mmepụta gụnyere ọtụtụ RF ngwakọ ngwakọ, DC superposition, RF jikọtara ya na DC pulse bias, na synchronous pulsed RF mmepụta nke mbuso agha ike na isi iyi.

Ngwa CCP etching bụ otu n'ime ụdị ngwa etching plasma abụọ a na-ejikarị. A na-ejikarị eme ihe na usoro etching nke ihe dielectric, dị ka ọnụ ụzọ ámá na nkpuchi siri ike etching na n'ihu ogbo nke mgbawa mgbawa, kọntaktị oghere etching na etiti ogbo, mosaic na aluminum pad etching na azụ ogbo, yana etching nke miri trenches, miri oghere na wiring kọntaktị oghere na 3D flash memory mgbawa usoro (na-ewere silicon nitride/silicon oxide Ọdịdị dị ka ihe atụ).

Enwere isi ihe ịma aka abụọ na ntụzịaka nkwalite nke akụrụngwa CCP etching chere ihu. Nke mbụ, na ngwa nke ike ion dị elu, ikike etching nke akụkụ akụkụ dị elu (dịka oghere na oghere nke ebe nchekwa 3D flash chọrọ oke karịa 50: 1). Ụzọ dị ugbu a nke ịbawanye ike nhụsianya iji welie ike ion ejirila ike RF nke ruru 10,000 watts. N'ihi nnukwu ọkụ ọkụ na-emepụta, a na-eme ka nkà na ụzụ dị jụụ na njikwa okpomọkụ nke ụlọ mmeghachi omume na-aga n'ihu na-aga n'ihu. Nke abụọ, ọ dị mkpa ka enwere ọganihu na mmepe nke gas ọhụrụ etching iji dozie nsogbu nke ike etching.

4.6 Ngwa ejikọtara Plasma Etching Ngwakọta

Ngwa etching plasma (ICP) jikọtara ya na inductively bụ ngwaọrụ na-ejikọta ike nke isi iyi redio ugboro ugboro n'ime ụlọ mmeghachi omume n'ụdị magnetik site na eriri inductor, si otú ahụ na-emepụta plasma maka etching. Ụkpụrụ etching ya sokwa na ion etching a na-emeghachi omume n'ozuzu ya.

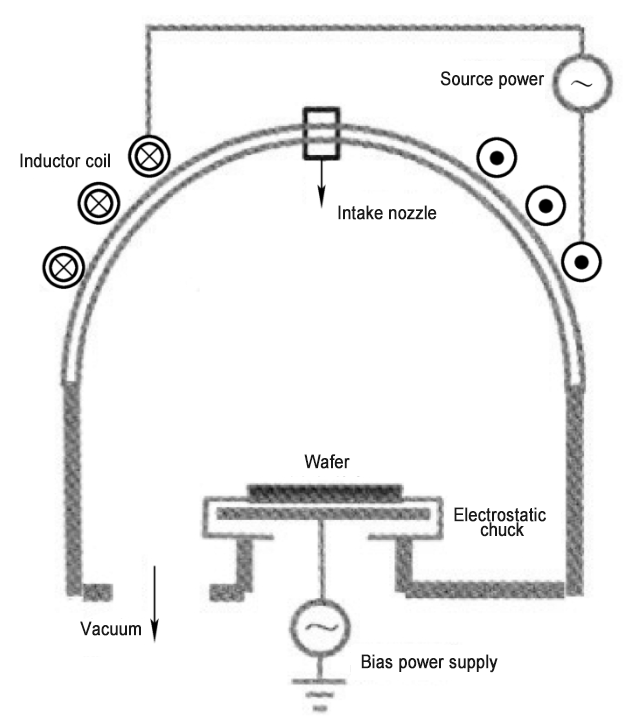

Enwere ụdị isi ihe abụọ dị na plasma maka akụrụngwa etching ICP. Otu bụ teknụzụ mgbanwe plasma (TCP) nke Lam Research mepụtara ma mepụta ya. A na-etinye eriri inductor ya n'ụgbọelu windo dielectric n'elu ụlọ mmeghachi omume. Mgbama 13.56MHz RF na-ewepụta oghere ndọta ọzọ na eriri igwe nke dị n'akụkụ windo dielectric ma na-atụgharị na axis eriri igwe dị ka etiti.

Igwe ndọta na-abanye n'ime ụlọ mmeghachi omume site na windo dielectric, na ebe ndọta na-agbanwe agbanwe na-emepụta ihe ọkụ eletrik na-agbanwe agbanwe na windo dielectric na ụlọ mmeghachi omume, si otú ahụ na-enweta dissociation nke etching gas na ịmepụta plasma. Ebe enwere ike ịghọta ụkpụrụ a dị ka ihe ntụgharị nwere eriri inductor dị ka ikuku mbụ na plasma dị na ụlọ mmeghachi omume dị ka ikuku nke abụọ, ICP etching ka akpọrọ aha ya.

Isi uru nke teknụzụ TCP bụ na nhazi ahụ dị mfe ịbawanye elu. Dịka ọmụmaatụ, site na wafer 200mm gaa na wafer 300mm, TCP nwere ike ịnọgide na-enwe mmetụta etching ahụ site na ịbawanye nha nke eriri igwe.

Nhazi isi iyi plasma ọzọ bụ teknụzụ plasma decoupled (DPS) nke Applied Materials, Inc. nke United States mepụtara ma mepụta ya. Igwe eriri inductor ya nwere mmerụ ahụ n'akụkụ atọ na windo dielectric nke dị n'akụkụ. Ụkpụrụ nke ịmepụta plasma yiri nkà na ụzụ TCP ahụ e kwuru n'elu, ma arụmọrụ dissociation gas dị oke elu, nke na-eme ka ị nweta mkpokọta plasma dị elu.

Ebe ọ bụ na arụmọrụ nke njikọ inductive iji mepụta plasma dị elu karịa nke njikọta capacitive, yana plasma na-emekarị na mpaghara dị nso na windo dielectric, a na-ekpebi itinye uche ya na plasma site na ike nke isi iyi ike na-ejikọta na inductor. eriri igwe, na ion ume na ion n'ọbọ n'elu nke wafer bụ isi kpebisiri ike site ike nke abias ike ọkọnọ, ya mere ịta na ike nke ion nwere ike ịbụ onwe ya. a na-achịkwa ya, si otú a na-enweta nkwụsịtụ.

Ngwa ICP etching bụ otu n'ime ụdị ngwa etching plasma abụọ a na-ejikarị. A na-ejikarị ya maka etching nke silicon na-emighị emeri trenches, germanium (Ge), ihe owuwu ọnụ ụzọ ámá polysilicon, ihe owuwu ụzọ ámá metal, silicon strained (Strained-Si), wires metal, pads (pads), mosaic etching metal siri ike masks na ọtụtụ usoro. otutu onyonyo teknụzụ.

Ke adianade do, na ịrị elu nke atọ akụkụ integrated sekit, CMOS image sensọ na micro-electro-mechanical usoro (MEMS), nakwa dị ka ngwa ngwa abawanye na ngwa nke site silicon vias (TSV), nnukwu-size oblique oghere na. miri etching silicon etching dị iche iche morphologies, ọtụtụ ndị na-emepụta ewepụtala etching akụrụngwa mepụtara kpọmkwem maka ndị a ngwa. Àgwà ya bụ nnukwu etching omimi (iriri ma ọ bụ ọbụna ọtụtụ narị microns), n'ihi ya, ọ na-emekarị na-arụ ọrụ n'okpuru elu gas eruba, elu mgbali na elu ike ọnọdụ.

———————————————————————————————————————————————————————— ————————————-

Semicera nwere ike inyeakụkụ graphite, mmetụta dị nro / siri ike, akụkụ silicon carbide, Akụkụ CVD silicon carbide, naAkụkụ SiC/TaC mkpuchin'ime ụbọchị 30.

Ọ bụrụ na ị nwere mmasị na ngwaahịa semiconductor ndị a,biko egbula oge ịkpọtụrụ anyị na oge mbụ.

Tel: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Oge nzipu: Ọgọst-31-2024