1. Okwu mmalite

A na-akpọ usoro ijikọ ihe (raw material) n'elu ihe ndị dị n'elu site na usoro anụ ahụ ma ọ bụ kemịkalụ nke ihe nkiri dị mkpa.

Dị ka ụkpụrụ ọrụ dị iche iche si dị, enwere ike kewaa ntinye ihe nkiri mkpagharị sekit n'ime:

-Mkpokọta uzuoku nke anụ ahụ (PVD);

-Chemical Vapor Deposition (CVD);

- Mgbatị.

2. Usoro uto ihe nkiri dị mkpa

2.1 Ntunye uzuoku anụ ahụ na usoro ịgbasa mmiri

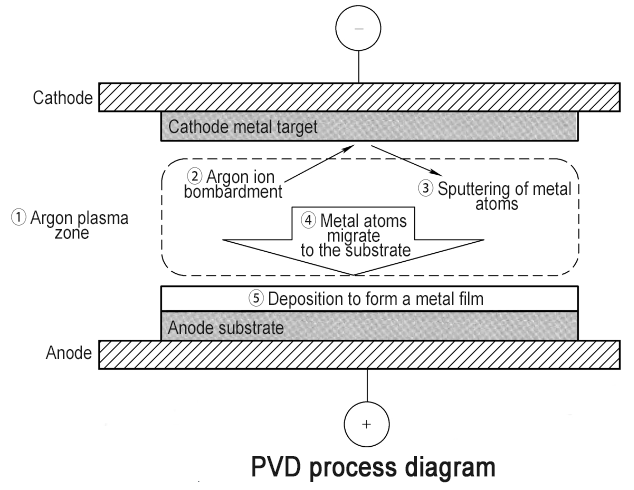

Usoro ntinye ikuku anụ ahụ (PVD) na-ezo aka na iji ụzọ anụ ahụ dị ka ikuku evaporation, sputtering, mkpuchi plasma na molecular beam epitaxy iji mepụta ihe nkiri dị mkpa n'elu wafer.

N'ime ụlọ ọrụ VLSI, teknụzụ PVD a na-ejikarị eme ihe bụ sputtering, nke a na-ejikarị maka electrodes na njikọ ígwè nke sekit agbakwunyere. Ịgbasa bụ usoro nke na-etinye gas na-adịghị ahụkebe [dị ka argon (Ar)] n'ime ion (dị ka Ar +) n'okpuru ọrụ nke eletrik eletrik dị n'èzí n'okpuru ọnọdụ ikuku dị elu, ma na-atụba isi ihe e lekwasịrị anya n'okpuru ebe dị elu, ịkụpụ atom ma ọ bụ ụmụ irighiri ihe ndị e lekwasịrị anya, wee rute n'elu wafer iji mepụta ihe nkiri dị mkpa mgbe usoro ụgbọ elu na-enweghị nkukota. Ar nwere akụrụngwa kemịkalụ kwụsiri ike, ion ya agaghị emeghachi omume kemịkalụ na ihe ebumnuche na ihe nkiri ahụ. Ka ibe sekit agbakwunyere na-abanye na oge njikọ njikọta ọla kọpa 0.13μm, oyi akwa ihe mgbochi ọla kọpa na-eji ihe nkiri titanium nitride (TiN) ma ọ bụ tantalum nitride (TaN). Ọchịchọ maka teknụzụ ụlọ ọrụ akwalitela nyocha na mmepe nke teknụzụ mmeghachi omume kemịkalụ sputtering, ya bụ, n'ime ụlọ sputtering, na mgbakwunye na Ar, e nwekwara reactive gas nitrogen (N2), nke mere na Ti ma ọ bụ Ta bombarded si. Ihe ebumnuche Ti ma ọ bụ Ta na-emeghachi omume na N2 iji mepụta ihe nkiri TiN ma ọ bụ TaN achọrọ.

Enwere ụzọ atọ a na-ejikarị agbasa, ya bụ DC sputtering, RF sputtering na magnetron sputtering. Ka njikọta nke sekit ndị jikọtara ọnụ na-aga n'ihu na-abawanye, ọnụ ọgụgụ nke ọkwa nke wiwi metal multi-layer na-abawanye, na ngwa nke teknụzụ PVD na-abawanye ụba. Ihe PVD gụnyere Al-Si, Al-Cu, Al-Si-Cu, Ti, Ta, Co, TiN, TaN, Ni, WSi2, wdg.

PVD na sputtering usoro na-emekarị dechara na a ukwuu akara mmeghachi omume ụlọ na a agụụ ogo nke 1 × 10-7 ka 9 × 10-9 Torr, nke nwere ike hụ na ịdị ọcha nke gas n'oge mmeghachi omume; n'otu oge ahụ, a na-achọrọ voltaji dị elu dị n'èzí iji ionize gas na-adịghị ahụkebe iji mepụta voltaji dị elu zuru oke iji tụọ ihe mgbaru ọsọ. Ihe ndị bụ isi maka ịlele PVD na usoro ịgbasa sputtering gụnyere ọnụ ọgụgụ nke uzuzu, yana uru nguzogide, ịdị n'otu, ịdị nro na-atụgharị uche na nrụgide nke ihe nkiri ahụ kpụrụ.

2.2 Usoro mkposa uzuoku kemịkalụ na usoro ịgbasa

Chemical vapor deposition (CVD) na-ezo aka na nkà na ụzụ usoro nke a dịgasị iche iche nke gaseous reactants dị iche iche ele mmadụ anya n'ihu nrụgide na-emeghachi omume chemical na a ụfọdụ okpomọkụ na nrụgide, na eme siri ike bekee na-edebe n'elu nke mkpụrụ ihe iji nweta chọrọ mkpa mkpa. ihe nkiri. N'ime usoro mmepụta sekit agbakwunyere ọdịnala, ihe ihe nkiri dị mkpa enwetara bụ mkpokọta dịka oxides, nitrides, carbides, ma ọ bụ ihe ndị dị ka silicon polycrystalline na silicon amorphous. Ọganihu epitaxial ahọpụtara, nke a na-ejikarị eme ihe mgbe oghere 45nm, dị ka isi iyi na igbapu SiGe ma ọ bụ Si nhọrọ epitaxial uto, bụkwa teknụzụ CVD.

Teknụzụ a nwere ike ịga n'ihu na-etolite otu ihe kristal nke otu ụdị ma ọ bụ yiri lattice mbụ na otu mkpụrụ kristal nke silicon ma ọ bụ ihe ndị ọzọ n'akụkụ lattice mbụ. A na-eji CVD eme ihe n'ọtụtụ ebe na uto nke ihe nkiri dielectric mkpuchi (dị ka SiO2, Si3N4 na SiON, wdg) na ihe nkiri ígwè (dị ka tungsten, wdg).

N'ozuzu, dị ka nhazi ọkwa nrụgide, CVD nwere ike kewaa n'ime ikuku ikuku kemịkalụ vapor deposition (APCVD), sub-atmosphere pressure chemical vepor deposition (SAPCVD) na obere nrụgide vapor deposition (LPCVD).

Dị ka okpomọkụ nhazi ọkwa, CVD nwere ike kewaa n'ime elu okpomọkụ / ala okpomọkụ oxide film kemịkalụ vepor deposition (HTO/LTO CVD) na ngwa ngwa thermal chemical vapor deposition (Rapid Thermal CVD, RTCVD);

Dị ka mmeghachi omume mmeghachi omume, CVD nwere ike kewaa silane dabeere CVD, polyester dabeere CVD (TEOS dabeere CVD) na metal organic chemical vapor deposition (MOCVD);

Dị ka ike nhazi ọkwa, CVD nwere ike kewaa n'ime thermal chemical vapor deposition (Thermal CVD), plasma enhanced chemical vapor deposition (Plasma Enhanced CVD, PECVD) na nnukwu njupụta plasma kemịkalụ vapor deposition (High Density Plasma CVD, HDPCVD). N’oge na-adịbeghị anya, ewepụtala ntinye kemịkalụ kemịkalụ (CVD Flowable, FCVD) nwere ikike ndochi oghere mara mma.

Ihe nkiri CVD dị iche iche nwere ihe dị iche iche (dịka ihe mejupụtara kemịkalụ, dielectric na-adịgide adịgide, esemokwu, nrụgide na voltaji ndakpọ) na enwere ike iji ya dị iche iche dị ka usoro dị iche iche chọrọ (dịka okpomọkụ, mkpuchi nzọụkwụ, ndochi chọrọ, wdg).

2.3 Usoro ntinye nke oyi akwa atomic

Atọm oyi akwa (ALD) na-ezo aka na nkwụnye nke atọm oyi akwa site oyi akwa n'elu ihe onwunwe site na-eto otu atomiki film oyi akwa site oyi akwa. Otu ALD na-ahụkarị na-anabata usoro nke itinye ihe gaseous precursors n'ime reactor n'ụzọ ọzọ pulsed.

Dịka ọmụmaatụ, nke mbụ, a na-ewebata precursor mmeghachi omume 1 n'ime ala nke mkpụrụ, na mgbe mgbasa ozi kemịkalụ gasịrị, a na-emepụta otu oyi akwa atomic n'elu ala; mgbe ahụ precursor 1 fọdụrụ n'elu mkpụrụ osisi na n'ime ụlọ mmeghachi omume na-agbapụta site na mgbapụta ikuku; mgbe ahụ mmeghachi omume precursor 2 ewebata n'ime mkpụrụ n'elu, na kemịkalụ na-emeghachi omume na precursor 1 adsorbed n'elu mkpụrụ n'elu ka n'ịwa kwekọrọ ekwekọ mkpa film ihe na kwekọrọ ekwekọ site-products na substrate elu; mgbe precursor 1 na-emeghachi omume kpamkpam, mmeghachi omume ahụ ga-akwụsị ozugbo, nke bụ njirimara na-egbochi onwe ya nke ALD, mgbe ahụ, a na-ewepụta ihe ndị fọdụrụ na reactants na ngwaahịa ndị ọzọ iji kwadebe maka ọkwa ọzọ nke uto; site na ikwughachi usoro a n'elu na-aga n'ihu, enwere ike nweta ntinye nke ihe nkiri ihe nkiri toro oyi akwa site na oyi akwa nwere otu atọm.

Ma ALD na CVD bụ ụzọ ewebata isi iyi mmeghachi omume kemịkalụ gaseous iji meghachi omume kemịkalụ n'elu mkpụrụ, mana ihe dị iche bụ na isi iyi mmeghachi omume gas nke CVD enweghị njirimara nke na-egbochi uto onwe ya. Enwere ike ịhụ na isi ihe na-emepe teknụzụ ALD bụ ịchọta ndị na-ebu ụzọ nwere njirimara mmeghachi omume na-egbochi onwe ya.

2.4 Usoro Epitaxial

Usoro epitaxial na-ezo aka na usoro nke itolite otu oyi akwa kristal nyere iwu zuru oke na mkpụrụ. N'ikwu okwu n'ozuzu, usoro epitaxial bụ itolite oyi akwa kristal nwere otu ntụzịaka lattice dị ka mkpụrụ nke mbụ na otu mkpụrụ kristal. A na-eji usoro epitaxial eme ihe na nrụpụta semiconductor, dị ka silicon wafers na ụlọ ọrụ sekit agbakwunyere, isi iyi na igbapu epitaxial uto nke MOS transistor, uto epitaxial na mkpụrụ LED, wdg.

Dị ka usoro dị iche iche nke isi mmalite nke uto si dị, usoro uto epitaxial nwere ike kewaa n'ime akụkụ epitaxy siri ike, mmiri mmiri epitaxy, na vapor phase epitaxy. N'ime mmepụta sekit agbakwunyere, ụzọ epitaxial a na-ejikarị bụ akụkụ epitaxy siri ike na vepor phase epitaxy.

Akụkụ siri ike nke epitaxy: na-ezo aka uto nke otu oyi akwa kristal na mkpụrụ na-eji isi iyi siri ike. Dịka ọmụmaatụ, mgbakasị ahụ ọkụ mgbe etinyere ion bụ n'ezie usoro epitaxy nke siri ike. N'oge a na-etinye ion ion, atom silicon atom nke silicon wafer na-agbaze site na ion ume ike dị elu, na-ahapụ ọnọdụ lattice mbụ ha na-aghọ amorphous, na-eme elu silicon amorphous oyi akwa. Mgbe ikpochapụ okpomọkụ dị elu, atom amorphous na-alaghachi n'ọnọdụ lattice ha wee nọgide na-adaba na ntụgharị kristal atomic n'ime mkpụrụ.

Ụzọ uto nke vapor frasi epitaxy gụnyere kemịkalụ vapor frasi epitaxy, molecular beam epitaxy, atomic Layer epitaxy, wdg N'ime nrụpụta sekit agbakwunyere, kemịkalụ vapor frasi epitaxy bụ nke a na-ejikarị eme ihe. Ụkpụrụ nke kemịkalụ vapor phase epitaxy bụ n'ụzọ bụ isi na nke ntinye mmiri nke kemịkal. Ha abụọ bụ usoro na-edobe ihe nkiri ndị dị gịrịgịrị site na-emeghachi omume na kemịkalụ n'elu wafer mgbe agwakọta gas.

Ihe dị iche bụ na n'ihi na kemịkalụ vapor phase epitaxy na-eto otu oyi akwa kristal, ọ nwere ihe dị elu chọrọ maka ọdịnaya adịghị ọcha na ngwa na ịdị ọcha nke elu wafer. Ekwesịrị ịme usoro silicon vapor nke mbụ n'okpuru ọnọdụ okpomọkụ dị elu (karịa 1000 Celsius C). Na mmelite nke usoro akụrụngwa, karịsịa nnabata nke oghere mgbanwe ụlọ technology, ịdị ọcha nke oghere akụrụngwa na elu nke silicon wafer e ukwuu mma, na silicon epitaxy nwere ike rụrụ na a ala okpomọkụ (600-700 °). C). Usoro wafer silicon epitaxial bụ itolite oyi akwa silicon kristal n'elu wafer silicon.

E jiri ya tụnyere ihe mbụ silicon oyi akwa, epitaxial silicon oyi akwa nwere ịdị ọcha dị elu yana mpe mpe mpe mpe akwa, si otú a na-emeziwanye mkpụrụ nke nrụpụta semiconductor. Tụkwasị na nke ahụ, a na-eme ka ọkpụkpụ na-eto eto na ntinye doping nke oyi akwa silicon epitaxial toro na silicon wafer nwere ike ịhazi ya nke ọma, nke na-eweta mgbanwe na nhazi nke ngwaọrụ ahụ, dị ka ibelata nguzogide mkpụrụ na ịkwalite ikewapụ mkpụrụ. Usoro epitaxial isi iyi-mmiri agbakwunyere bụ teknụzụ a na-ejikarị na ọnụ teknụzụ mgbagha dị elu.

Ọ na-ezo aka na usoro nke silikoni germanium ma ọ bụ silicon na-eto eto epitaxially na isi iyi na mpaghara mgbapu nke MOS transistor. Uru ndị bụ isi nke iwebata usoro epitaxial isi iyi-mmiri agbakwunyere gụnyere: na-eto eto oyi akwa pseudocrystalline nwere nrụgide n'ihi ngbanwe nke lattice, na-eme ka ọwa na-ebugharị ọwa; n'ime ebe doping nke isi iyi na igbapu nwere ike ibelata nguzogide parasitic nke isi iyi-mmiri mmiri na-ebelata ntụpọ nke ntinye ion ike dị elu.

3. mkpa film ibu akụrụngwa

3.1 Vacuum evaporation akụrụngwa

Vacuum evaporation bụ usoro mkpuchi nke na-ekpo ọkụ ihe ndị siri ike n'ime oghere na-ekpo ọkụ iji mee ka ha kpochaa, vaporize ma ọ bụ sublimate, wee kpochie ma tinye n'elu ihe mpempe akwụkwọ n'otu okpomọkụ.

Ọ na-enwekarị akụkụ atọ, ya bụ usoro agụụ, usoro evaporation na usoro kpo oku. Usoro agụụ ahụ nwere ọkpọkọ na-ekpo ọkụ na nfuli ikuku, na ọrụ ya bụ isi bụ inye ebe ikuku oghere ruru eru maka evaporation. Usoro evaporation na-agụnye tebụl evaporation, ihe na-ekpo ọkụ na ihe nkedo okpomọkụ.

A na-etinye ihe a na-achọsi ike na-ekpochapụ (dịka Ag, Al, wdg) na tebụl evaporation; ihe na-ahụ maka ikpo ọkụ na okpomọkụ bụ usoro mechiri emechi nke a na-eji na-achịkwa okpomọkụ nke evaporation iji hụ na ikuku na-ekpo ọkụ. Usoro ikpo ọkụ na-agụnye ọkwa wafer na ihe ọkụkụ. A na-eji ogbo wafer na-etinye mkpụrụ nke ihe nkiri ahụ dị mkpa ka a ga-ekpochapụ, a na-ejikwa akụrụngwa kpo oku mee ihe iji ghọta ihe nchịkwa kpo oku na njikwa okpomọkụ.

Ebe ikuku na-ekpo ọkụ bụ ọnọdụ dị oke mkpa na usoro ikuku evaporation, nke metụtara ọnụọgụ evaporation na àgwà nke ihe nkiri ahụ. Ọ bụrụ na ogo agụụ ahụ emezughị ihe a chọrọ, atom ma ọ bụ ụmụ irighiri ihe ndị ahụ vaporized ga-adaba ugboro ugboro na ụmụ irighiri gas fọdụrụnụ, na-eme ka ụzọ ha nwere n'efu dị ntakịrị, na atom ma ọ bụ ụmụ irighiri ihe ga-agbasasị nke ukwuu, si otú ahụ na-agbanwe ụzọ mmegharị ahụ ma belata ihe nkiri ahụ. nguzobe ọnụego.

Tụkwasị na nke ahụ, n'ihi ọnụnọ nke ikuku gas na-adịghị ọcha, ihe nkiri ahụ a na-etinye na ya na-emetọ nke ọma na nke na-adịghị mma, karịsịa ma ọ bụrụ na ọnụ ọgụgụ nrụgide nke ụlọ ahụ eruteghị ọkọlọtọ ma enwere nkwụsị, ikuku ga-adaba n'ime oghere oghere. , nke ga-enwe mmetụta siri ike na àgwà ihe nkiri ahụ.

Njirimara nhazi nke akụrụngwa ikuku evaporation na-achọpụta na ịdị n'otu nke mkpuchi na nnukwu ihe ndị dị oke adịghị mma. Iji mee ka ịdị n'otu ya dịkwuo mma, a na-anakwere usoro nke ịbawanye anya-substrate anya na ịtụgharị mkpụrụ osisi ahụ, mana ịba ụba nke isi iyi substrate ga-achụ àjà uto na ịdị ọcha nke ihe nkiri ahụ. N'otu oge ahụ, n'ihi mmụba nke oghere oghere, ọnụ ọgụgụ ojiji nke ihe a na-ekpochapụ na-ebelata.

3.2 DC anụ ahụ ikuku ntinye akụrụngwa

A na-akpọkwa nkwụnye ikuku anụ ahụ ugbu a kpọmkwem (DCPVD) dị ka sputtering cathode ma ọ bụ vacuum DC sputtering nkeji abụọ. A na-eji ihe e lekwasịrị anya nke ikuku DC sputtering dị ka cathode na mkpụrụ a na-eji dị ka anode. Mgbasa ikuku bụ ịmepụta plasma site na ionization nke usoro gas.

A na-emewanye ihe ndị a na-ebubo na plasma na ọkụ eletrik iji nweta ume ụfọdụ. Ihe ndị ahụ nwere ike zuru oke na-atụ bọmbụ n'elu ihe a na-achọsi ike, nke mere na atom ndị e lekwasịrị anya na-awụsa; Atọm ndị ahụ gbasasịrị nwere ụfọdụ ike kinetic na-aga na mkpụrụ osisi ka ha mepụta ihe nkiri dị mkpa n'elu mkpụrụ ahụ. Igwe ọkụ a na-eji agbasa bụkarị gas na-adịghị ahụkebe, dị ka argon (Ar), n'ihi ya, ihe nkiri a na-emepụta site na sputtering agaghị emerụ; na mgbakwunye, radius atomic nke argon dị mma maka ịgbasa.

Nha nke irighiri ihe na-efesa ga-adịrịrị nso nha nke atọm ebu n'obi ka a ga-efesa. Ọ bụrụ na ụmụ irighiri ihe ndị ahụ buru ibu ma ọ bụ dị ntakịrị, enweghị ike ịmepụta sputtering dị irè. Na mgbakwunye na nha nha nke atọm, oke ihe nke atom ga-emetụtakwa àgwà sputtering. Ọ bụrụ na ndị sputtering urughuru iyi bụ oke ìhè, lekwasịrị atọ atọ agaghị sputtered; ọ bụrụ na ụmụ irighiri ihe na-efesa dị oke arọ, a ga-ehulata ihe a ga-ehulata, a gaghịkwa agbasa ihe e lekwasịrị anya.

Ihe ebumnuche ejiri na DCPVD ga-abụrịrị onye nduzi. Nke a bụ n'ihi na mgbe ion argon na usoro gas na-atụba ihe ezubere iche, ha ga-ejikọta ya na electrons n'elu ihe a na-achọsi ike. Mgbe ihe e lekwasịrị anya bụ onye na-eduzi ihe dị ka ígwè, electrons ndị a na-eri site na nchikota a na-adị mfe imeju site na ọkụ eletrik na ndị electrons n'efu n'akụkụ ndị ọzọ nke ihe ezubere iche site na ntụgharị ọkụ eletrik, nke mere na elu nke ihe a na-eche n'echiche dị ka a. A na-edobe ihe niile n'ụzọ na-adịghị mma ma na-edobe sputtering.

N'ụzọ megidere nke ahụ, ọ bụrụ na ihe e lekwasịrị anya bụ ihe mkpuchi, mgbe a na-ejikọta electrons n'elu nke ihe a na-achọsi ike, electrons n'efu n'akụkụ ndị ọzọ nke ihe a na-eche n'echiche enweghị ike imeju site na ọkụ eletrik, na ọbụna ụgwọ dị mma ga-agbakọta na elu nke ihe a na-achọsi ike, na-eme ka ihe ndị e lekwasịrị anya na-ebuli elu, na ụgwọ ọrụ na-adịghị mma nke ihe a na-atụ anya na-ebelata ruo mgbe ọ ga-apụ n'anya, n'ikpeazụ na-eduga ná nkwụsị nke sputtering.

Ya mere, iji mee ka ihe ndị na-ekpuchi ihe na-eme ka ọ bụrụkwa ihe eji eme ihe maka sputtering, ọ dị mkpa ịchọta usoro ịgbasa ọzọ. Mgbasa mgbasa ozi ugboro redio bụ usoro ịgbasa nke dabara adaba maka ebumnuche na-eduzi na nke anaghị eduzi ya.

Mwepu ọzọ nke DCPVD bụ na voltaji mgbanye dị elu na bọmbụ eletrọn na mkpụrụ ahụ siri ike. Ụzọ dị irè isi dozie nsogbu a bụ iji magnetron sputtering, ya mere magnetron sputtering bụ n'ezie bara uru bara uru na ubi nke integrated sekit.

3.3 RF Ngwa Ndobe Uzuoku Anụ ahụ

Ntube ikuku anụ ahụ ugboro ugboro redio (RFPVD) na-eji ike ugboro redio dị ka ihe mkpali na bụ usoro PVD dabara adaba maka igwe dị iche iche na ihe na-abụghị igwe.

Ugboro ugboro nke ọkụ ọkụ RF ejiri na RFPVD bụ 13.56MHz, 20MHz, na 60MHz. Usoro dị mma na nke na-adịghị mma nke ọkụ ọkụ RF na-apụta n'ụzọ ọzọ. Mgbe PVD lekwasịrị anya dị na mma ọkara okirikiri, n'ihi na lekwasịrị anya n'elu bụ na a mma ikike, electrons na usoro ikuku ga-eruba na lekwasịrị n'elu ka neutralize nti ụgwọ akwakọba n'elu ya, na ọbụna nọgide na-akwakọba electrons, na-eme ka elu ya bụrụ ihe na-adịghị mma; mgbe ebumnuche sputtering dị na okirikiri ọkara na-adịghị mma, ion ndị dị mma ga-aga n'ihu na ebumnuche ma bụrụ nke a na-anọpụ iche na elu ebumnuche.

Ihe kachasị mkpa bụ na ọsọ ọsọ nke electrons na mpaghara eletriki RF dị ngwa ngwa karịa nke ion dị mma, ebe oge nke ọkara nke ọma na nke na-adịghị mma bụ otu, ya mere, mgbe okirikiri zuru oke, ihe a na-eche n'elu ga-adị. "net" ebubo na-adịghị mma. Ya mere, na cycles ole na ole mbụ, ụgwọ na-adịghị mma nke elu ezubere iche na-egosi ọganihu na-arịwanye elu; emesia, ebum n'obi na-erute ikike ọjọọ kwụsiri ike; Mgbe nke ahụ gasịrị, n'ihi na ebubo na-adịghị mma nke ihe mgbaru ọsọ ahụ nwere mmetụta na-asọ oyi na electrons, ọnụ ọgụgụ nke ụgwọ dị mma na nke na-adịghị mma natara site na electrode lekwasịrị anya na-eme ka ọ dị mma, na ihe mgbaru ọsọ na-enye ụgwọ ọrụ na-adịghị mma.

Site na usoro a dị n'elu, a pụrụ ịhụ na usoro nke mmepụta voltaji na-adịghị mma enweghị ihe jikọrọ ya na njirimara nke ihe a na-eche n'onwe ya, ya mere, usoro RFPVD nwere ike ọ bụghị nanị dozie nsogbu nke sputtering nke mkpuchi mkpuchi, kamakwa ọ dabara nke ọma. na ot metal conductor zaa.

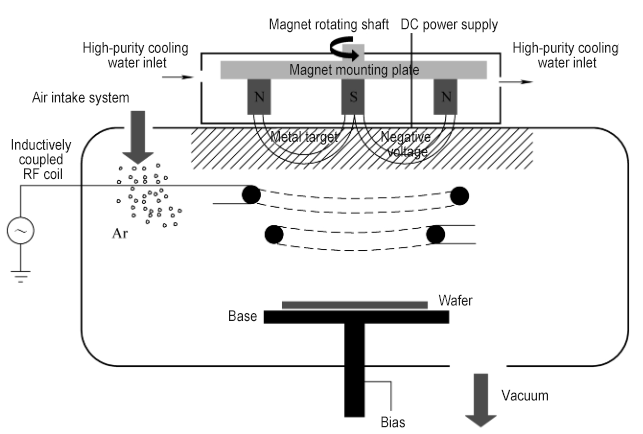

3.4 Magnetron sputtering akụrụngwa

Ịgbasa Magnetron bụ usoro PVD na-agbakwunye magnet na azụ nke ebumnuche. Ihe ndọta agbakwunyere na sistemụ ọkụ DC (ma ọ bụ ọkụ ọkụ AC) na-etolite isi iyi na-efesa magnetron. A na-eji isi iyi sputtering na-etolite oghere electromagnetic na-emekọrịta ihe n'ime ụlọ ahụ, jide ma kpachie mmegharị nke electrons na plasma n'ime ụlọ ahụ, gbasaa ụzọ mmegharị nke electrons, wee si otú a na-abawanye ntinye nke plasma, ma mechaa nwetakwuo ihe. ntinye ego.

Tụkwasị na nke ahụ, n'ihi na a na-ejikọta ọtụtụ electrons n'akụkụ elu nke ihe mgbaru ọsọ ahụ, bọmbụ nke electrons na-ebelata, na okpomọkụ nke mkpụrụ ahụ na-ebelata. E jiri ya tụnyere teknụzụ DCPVD dị larịị, otu n'ime njirimara pụtara ìhè nke teknụzụ ikuku ikuku magnetron bụ na voltaji mwepu mgbanye dị ala ma kwụsie ike.

N'ihi itinye uche ya dị elu na plasma ya na mkpụrụ sputtering buru ibu, ọ nwere ike nweta nrụpụta nrụpụta dị mma, njikwa nha nha n'ogo buru ibu, njikwa ihe mejupụtara ya na voltaji mgbanye dị ala. Ya mere, magnetron sputtering nọ n'ọnọdụ kachasị na ihe nkiri igwe ugbu a PVD. Ihe kacha dị mfe magnetron sputtering imewe bụ itinye otu ndọta n'azụ nke ebumnuche dị larịị (n'èzí sistemụ agụụ) iji mepụta oghere magnetik yiri elu ebumnuche na mpaghara mpaghara n'elu ebumnuche.

Ọ bụrụ na etinye magnet na-adịgide adịgide, a na-edozi oghere magnetik ya, na-ebute nkesa oghere magnetik dị ntakịrị n'elu ebe e lekwasịrị anya n'ime ụlọ ahụ. Naanị ihe ndị dị na mpaghara ụfọdụ nke ebumnuche ka a na-efesa, ọnụego ojiji ebumnuche dị ala, na ịdị n'otu nke ihe nkiri a kwadebere adịghị mma.

Enwere ụfọdụ ihe gbasara nke puru omume na a ga-edobere igwe a gbasasịrị efesa ma ọ bụ ihe ndị ọzọ n'elu ebe a na-achọghị, si otú ahụ na-agbakọta n'ime irighiri ihe ma na-akpụ ntụpọ. Ya mere, azụmahịa magnetron sputtering isi mmalite na-ejikarị ihe ndọta na-atụgharị agbagharị iji kwalite ịdị n'otu ihe nkiri, ọnụego ebumnuche ebumnuche, yana ịgbasa ebumnobi zuru oke.

Ọ dị mkpa iji dozie ihe atọ a. Ọ bụrụ na a naghị edozi nguzozi nke ọma, ọ nwere ike ịkpata otu ihe nkiri dị mma ma na-ebelata ọnụ ọgụgụ nke ebumnuche ebumnuche (na-ebelata ndụ ebumnuche), ma ọ bụ ịghara imezu mkpochapụ ebumnuche zuru oke ma ọ bụ corrosion ebumnuche zuru oke, nke ga-ebute nsogbu irighiri n'oge sputtering. usoro.

Na teknụzụ magnetron PVD, ọ dị mkpa ịtụle usoro mmegharị magnet na-atụgharị, ọdịdị ebumnuche, sistemụ jụrụ oyi na isi iyi magnetron, yana nhazi ọrụ nke isi na-ebu wafer, dị ka mgbasa ozi wafer na njikwa okpomọkụ. Na usoro PVD, a na-achịkwa okpomọkụ nke wafer iji nweta nhazi kristal achọrọ, nha ọka na nhazi, yana nkwụsi ike nke arụmọrụ.

Ebe ọ bụ na njikwa okpomọkụ dị n'etiti azụ nke wafer na elu nke isi na-achọ ụfọdụ nrụgide, na-emekarị n'usoro nke ọtụtụ Torr, na nrụgide ọrụ nke ụlọ ahụ na-abụkarị n'usoro nke ọtụtụ mTorr, nrụgide na azụ. nke wafer dị nnọọ ukwuu karịa nrụgide dị n'elu elu nke wafer ahụ, ya mere a na-achọsi ike na-arụ ọrụ ma ọ bụ electrostatic chuck iji tinye ma gbochie wafer.

Igwe igwe na-arụ ọrụ na-adabere na ibu nke ya na nsọtụ wafer iji nweta ọrụ a. Ọ bụ ezie na ọ nwere uru nke usoro dị mfe na enweghị uche na ihe onwunwe nke wafer, mmetụta dị n'akụkụ nke wafer ahụ doro anya, nke na-adịghị mma na njikwa siri ike nke ihe ndị ahụ. Ya mere, ejirila electrostatic chuck dochie ya nke nta nke nta na usoro nrụpụta IC.

Maka usoro ndị na-adịghị emetụ n'ahụ okpomọkụ, a pụkwara iji usoro nchekwa kọntaktị na-abụghị nke mgbasa ozi (enweghị ọdịiche dị n'etiti elu na ala nke wafer). N'oge usoro PVD, a ga-edobe ihe mkpuchi ụlọ na elu nke akụkụ ahụ na kọntaktị na plasma ma kpuchie ya. Mgbe ọkpụrụkpụ ihe nkiri ahụ echekwabara gafere oke, ihe nkiri ahụ ga-agbawa ma bepụ ya, na-akpata nsogbu irighiri.

Ya mere, ọgwụgwọ elu nke akụkụ ndị dị ka mkpuchi bụ isi ihe na-agbatị oke a. Ịgba ájá ájá dị n'elu na ịgbasa aluminum bụ ụzọ abụọ a na-ejikarị eme ihe, nzube ya bụ ime ka ọkpụkpụ dị elu dịkwuo elu iji mee ka njikọ dị n'etiti ihe nkiri ahụ na mkpuchi elu.

3.5 Ngwa ionization vepor nke anụ ahụ

Site na mmepe nke teknụzụ microelectronics na-aga n'ihu, nha njirimara na-adị ntakịrị na obere. Ebe ọ bụ na teknụzụ PVD enweghị ike ijikwa ntụzịaka ntinye nke irighiri ihe, ikike nke PVD ịbanye site na oghere na ọwa dị warara nwere oke akụkụ dị elu nwere oke, na-eme ka ịgbasa ngwa nke teknụzụ PVD ọdịnala na-amawanye aka. N'ime usoro PVD, ka akụkụ akụkụ nke oghere pore na-abawanye, mkpuchi dị na ala na-ebelata, na-eme ihe mkpuchi dị ka ihe mkpuchi dị n'akụkụ elu, na-eme ka mkpuchi na-adịghị ike na nkuku ala.

Emepụtara teknụzụ ntinye ionized anụ ahụ iji dozie nsogbu a. Ọ na-ebu ụzọ plasmatizes metal atoms sputtered si lekwasịrị anya n'ụzọ dị iche iche, na mgbe ahụ na-edozi elegidesi ike voltaji kwajuru na wafer iji chịkwaa ntụziaka na ume nke metal ion iji nweta a kwụsiri ike directional metal ion eruba iji kwadebe ihe nkiri dị mkpa, si otú ahụ na-emeziwanye. mkpuchi nke ala nke nzọụkwụ nke elu akụkụ ruru site oghere na warara ọwa.

Ihe a na-ahụkarị nke teknụzụ plasma metal ionized bụ mgbakwunye nke eriri igwe ugboro redio n'ime ụlọ. N'oge usoro ahụ, a na-edobe nrụgide na-arụ ọrụ nke ụlọ ahụ na ọnọdụ dị elu (5 ruo 10 ugboro nrụgide ọrụ nkịtị). N'oge PVD, a na-eji eriri igwe redio na-emepụta mpaghara plasma nke abụọ, nke ntinye plasma argon na-abawanye site na mmụba nke ike redio na nrụgide gas. Mgbe atom ọla ndị a na-agbapụta site na ebumnuche gafere mpaghara a, ha na plasma argon dị elu na-emekọ ihe iji mepụta ion ọla.

Itinye isi iyi RF n'ebe onye na-ebu wafer (dị ka chack electrostatic) nwere ike ịbawanye enweghị mmasị na wafer iji dọta ions metal dị mma na ala nke oghere pore. Igwe ion ntụzịaka a na-erugharị perpendicular na elu wafer na-eme ka mkpuchi steepụ dị ala nke pores akụkụ dị elu na ọwa dị warara.

Ihe na-adịghị mma a na-etinye na wafer na-emekwa ka ions na-agbaba n'elu wafer (mgbanwe ntụgharị), nke na-eme ka usoro ahụ dị elu nke ọnụ ọnụ pore dị ike ma na-atụgharị ihe nkiri ahụ na-etinye na ala n'akụkụ akụkụ nkuku nke ala nke pore. groove, si otú ahụ na-akwalite mkpuchi nzọụkwụ na nkuku.

3.6 Nrụgide ikuku kemịkalụ ikuku mgbakwasa akụrụngwa

Ngwa kemịkalụ kemịkalụ ikuku ikuku (APCVD) na-ezo aka na ngwaọrụ nke na-efesa isi iyi mmeghachi omume gaseous na ọsọ ọsọ mgbe niile na elu nke mkpụrụ siri ike na-ekpo ọkụ n'okpuru gburugburu ebe nrụgide dị nso na nrụgide ikuku, na-eme ka isi iyi mmeghachi omume na-emeghachi omume na kemịkalụ. ala mkpụrụ, na ngwaahịa mmeghachi omume na-edebe n'elu mkpụrụ n'elu na-etolite a mkpa ihe nkiri.

Ngwa APCVD bụ ngwa CVD mbụ ma a ka na-ejikwa ya na mmepụta ụlọ ọrụ na nyocha sayensị. Enwere ike iji ngwa APCVD kwadebe ihe nkiri ndị dị mkpa dị ka silicon kristal, polycrystalline silicon, silicon dioxide, zinc oxide, titanium dioxide, iko phosphosilicate, na iko borophosphosilicate.

3.7 Ngwá Ọrụ Ntụkwasị Mmiri Kemịkalụ Nrụgide

Ngwa kemịkalụ kemịkalụ dị ala (LPCVD) na-ezo aka na akụrụngwa nke na-eji akụrụngwa gas na-emeghachi kemịkalụ n'elu mkpụrụ osisi siri ike n'okpuru ebe a na-ekpo ọkụ (350-1100 ° C) na obere nrụgide (10-100mTorr), yana na reactants na-edebe na mkpụrụ n'elu na-etolite a mkpa ihe nkiri. A na-emepụta akụrụngwa LPCVD na ndabere nke APCVD iji melite ogo nke ihe nkiri dị gịrịgịrị, melite nha anya nkesa nke njirimara dị ka ọkpụrụkpụ ihe nkiri na resistivity, ma melite arụmọrụ mmepụta.

Isi ihe ya bụ na n'ime ebe ikuku ọkụ dị ala, usoro gas na-emeghachi omume na-eme ka mmiri dị n'elu nke mkpụrụ osisi wafer, na ngwaahịa mmeghachi omume na-echekwa n'elu ihe ntanetị iji mepụta ihe nkiri dị mkpa. Ngwa LPCVD nwere uru na nkwadebe nke ihe nkiri dị oke mma ma nwee ike iji kwadebe ihe nkiri dị mkpa dị ka silicon oxide, silicon nitride, polysilicon, silicon carbide, gallium nitride na graphene.

E jiri ya tụnyere APCVD, ọnọdụ mmeghachi omume dị ala nke akụrụngwa LPCVD na-abawanye ụzọ n'efu na mgbasa ozi nke gas na ụlọ mmeghachi omume.

The mmeghachi omume gas na ụgbọelu gas ụmụ irighiri na mmeghachi omume ụlọ nwere ike evenly kesaa n'ime a obere oge, si otú imeziwanye uniformity nke film ọkpụrụkpụ, resistivity uniformity na nzọụkwụ mkpuchi nke film, na oriri nke mmeghachi omume gas dịkwa obere. Tụkwasị na nke ahụ, gburugburu ebe obibi dị ala na-eme ka ngwa ngwa nnyefe nke ihe gas dị ngwa ngwa. A na-ewepụ ihe ndị na-adịghị ọcha na mmeghachi omume sitere na mkpụrụ osisi ahụ ngwa ngwa site na mpaghara mmeghachi omume site na oyi akwa ókè, na gas mmeghachi omume na-agafe ngwa ngwa site na oyi akwa nke oke iji ruo n'elu mkpụrụ maka mmeghachi omume, si otú a na-egbochi onwe-doping, na-akwadebe ngwa ngwa. ihe nkiri dị elu nke nwere mpaghara mgbanwe dị elu, ma na-emeziwanye mmepụta mmepụta ihe.

3.8 Akụrụngwa Mgbochi Uzuoku Dị Mma nke Plasma

Plasma enhanced chemical vapor deposition (PECVD) bụ ihe a na-ejikarị thin film ntinye teknụzụ. N'oge usoro plasma, a na-eme ka ihe na-aga n'ihu gaseous ionized n'okpuru ọrụ nke plasma na-etolite ìgwè ndị na-arụsi ọrụ ike, nke na-agbasa n'elu mkpụrụ osisi wee nweta mmeghachi omume kemịkalụ iji mechaa uto ihe nkiri ahụ.

Dị ka ugboro nke ọgbọ plasma, plasma eji na PECVD nwere ike kewaa ụzọ abụọ: redio ugboro plasma (RF plasma) na microwave plasma (Microwave plasma). Ugbu a, ugboro redio eji na ụlọ ọrụ na-abụkarị 13.56MHz.

A na-ekekarị iwebata plasma ugboro redio ụzọ abụọ: njikọta capacitive (CCP) na njikọ inductive (ICP). Usoro njikọta capacitive na-abụkarị usoro mmeghachi omume plasma ozugbo; ebe usoro njikọ inductive nwere ike ịbụ usoro plasma ozugbo ma ọ bụ usoro plasma dịpụrụ adịpụ.

N'ime usoro mmepụta nke semiconductor, a na-ejikarị PECVD eme ihe nkiri dị mkpa na ihe ndị nwere ọla ma ọ bụ ihe ndị ọzọ nwere mmetụta okpomọkụ. Dị ka ihe atụ, na ubi nke azụ-ọgwụgwụ metal interconnection nke integrated sekit, ebe ọ bụ na isi iyi, ọnụ ụzọ ámá na drain owuwu nke ngwaọrụ e guzobere na n'ihu ọgwụgwụ usoro, uto nke mkpa fim na ubi nke metal interconnection bụ isiokwu. na oke mgbochi mmefu ego ọkụ, yabụ a na-emecha ya site na enyemaka plasma. Site n'ịgbanwe usoro usoro plasma, njupụta, ihe mejupụtara kemịkalụ, ọdịnaya adịghị ọcha, ike arụ ọrụ na oke nrụgide nke ihe nkiri dị gịrịgịrị nke PECVD toro nwere ike mezie ma kwalite ya n'ime oke.

3.9 Akụrụngwa Atọmịk oyibo

Atọmịk oyi akwa (ALD) bụ teknụzụ ntinye ihe nkiri dị mkpa nke na-eto kwa oge n'ụdị oyi akwa monoatomic. Ihe e ji mara ya bụ na a pụrụ imezi ọkpụkpụ nke ihe nkiri a na-edebe ihe n'ụzọ ziri ezi site n'ịchịkwa ọnụ ọgụgụ nke cycles nke uto. N'adịghị ka usoro ntinye mmiri nke kemịkalụ (CVD), ihe abụọ (ma ọ bụ karịa) na-ebute ụzọ na usoro ALD ọzọ na-agafe n'elu mkpụrụ osisi wee kewapụ ya nke ọma site na ikpochapụ gas na-adịghị ahụkebe.

Ihe mmalite abụọ ahụ agaghị agwakọta ma zute n'oge gas ka ha meghachi omume na kemịkalụ, mana ọ na-emeghachi omume site na mgbasa ozi kemịkalụ n'elu mkpụrụ. N'ime okirikiri ALD nke ọ bụla, ọnụọgụ precursor etinyere n'elu mkpụrụ osisi metụtara njupụta nke otu nọ n'ọrụ n'elu mkpụrụ. Mgbe otu ndị na-emeghachi omume n'elu mkpụrụ ahụ gwụchara, ọ bụrụgodị na ewebata ngafe nke precursor, mgbasa ozi kemịkalụ agaghị eme n'elu mkpụrụ.

A na-akpọ usoro mmeghachi omume a mmeghachi omume na-amachi onwe ya elu. Usoro usoro a na-eme ka ọkpụrụkpụ nke ihe nkiri ahụ toro na usoro ọ bụla nke usoro ALD mgbe niile, ya mere, usoro ALD nwere uru nke njikwa nha nke ọma na mkpuchi mkpuchi ihe nkiri dị mma.

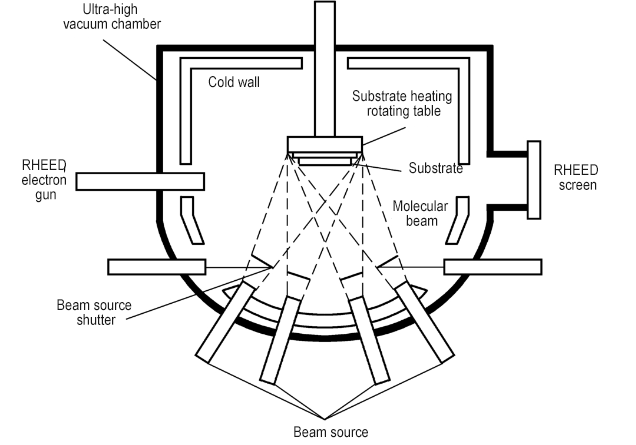

3.10 Ngwa Epitaxy Molecular Beam

Sistemụ Molecular Beam Epitaxy (MBE) na-ezo aka na ngwaọrụ epitaxial nke na-eji otu ma ọ bụ karịa thermal ume atomic beams ma ọ bụ molecular béam iji fesa n'elu mkpụrụ osisi kpụ ọkụ n'ọnụ n'otu ọsọ n'okpuru ọnọdụ ikuku dị oke elu, na-agbado ma kwaga n'elu ala. ka epitaxially tolite otu kristal mkpa ihe nkiri n'akụkụ axis kristal nke mkpụrụ ihe. N'ozuzu, n'okpuru ọnọdụ nke kpo oku site a jet oku na a okpomọkụ ọta, na doo isi iyi atomiki doo ma ọ bụ a molekụla doo, na film eto oyi akwa site oyi akwa tinyere crystal axis direction nke mkpụrụ ihe onwunwe.

Àgwà ya dị ala na-eto eto epitaxial, na ọkpụrụkpụ, interface, ihe mejupụtara kemịkalụ na ntinye adịghị ọcha nwere ike ịchịkwa nke ọma na ọkwa atọm. Ọ bụ ezie na MBE sitere na nkwadebe nke semiconductor ultra-thin single films, ngwa ya agbasawanyela ugbu a na usoro ihe dị iche iche dị ka ọla na ihe mkpuchi dielectrics, ma nwee ike ịkwadebe III-V, II-VI, silicon, silicon germanium (SiGe). ), graphene, oxides na ihe nkiri organic.

Usoro ihe omimi nke molecular beam epitaxy (MBE) bụ nke mejupụtara sistemu oghere dị oke elu, isi iyi ọkụ molecular, nhazi mkpụrụ na sistem kpo oku, sistemu mbufe ihe atụ, sistemụ nleba anya n'ime ọnọdụ, sistemu njikwa, na nnwale. usoro.

Usoro na-ekpo ọkụ na-agụnye nfuli oghere (mkpọ ọkụ na-arụ ọrụ, nfuli molecular, ion pumps, na condensation pumps, wdg) na valvụ dị iche iche, nke nwere ike ịmepụta gburugburu ebe na-eto eto na-ekpo ọkụ. Ọkwa oghere a na-enwetakarị bụ 10-8 ruo 10-11 Torr. Sistemụ na-ekpo ọkụ na-enwekarị ọnụ ụlọ atọ na-arụ ọrụ agụụ, ya bụ ụlọ ịgba ọgwụ sample, ụlọ pretreatment na elu nyocha ụlọ, na ụlọ uto.

A na-eji ụlọ injection sample na-ebufe ihe nlele na mpụga ụwa iji hụ na ọnọdụ ikuku dị elu nke ụlọ ndị ọzọ; ụlọ pretreatment na elu analysis ụlọ na-ejikọta sample injection ụlọ na ibu ụlọ, na ya isi ọrụ bụ tupu hazie sample (elu okpomọkụ degassing iji hụ na zuru ezu ịdị ọcha nke mkpụrụ n'elu) na ime mmalite n'elu nyocha na. ihe nlele nke kpochara; Ụlọ uto bụ akụkụ bụ isi nke usoro MBE, nke gụnyere isi ọkụ ọkụ na mgbakọ shutter kwekọrọ, ihe njikwa njikwa ihe njikwa, usoro jụrụ oyi, ntụgharị uche dị elu nke electron diffraction (RHEED), na usoro nlekota n'ime ọnọdụ. . Ụfọdụ akụrụngwa MBE na-emepụta nwere ọtụtụ nhazi ụlọ uto. E gosipụtara eserese schematic nke usoro akụrụngwa MBE n'okpuru:

MBE nke silicon ihe eji akwa-ọcha silicon dị ka akụrụngwa, na-etolite n'okpuru ultra-elu agụụ (10-10 ~ 10-11Torr) ọnọdụ, na ibu okpomọkụ bụ 600 ℃ 900 ℃, na Ga (P-ụdị) na Sb (. N-ụdị) dị ka isi mmalite doping. Isi mmalite doping a na-ejikarị eme ihe dị ka P, As na B adịghị adịkarị ka isi iyi n'ihi na ọ na-esi ike ịpụpụ.

Ụlọ mmeghachi omume nke MBE nwere ebe ikuku dị oke elu, nke na-eme ka ụzọ ụmụ irighiri ihe dị n'efu ma na-ebelata mmetọ na oxidation n'elu ihe na-eto eto. Ihe eji eme epitaxial a kwadebere nwere ezigbo ọdịdị elu na ịdị n'otu, a pụkwara ime ya ka ọ bụrụ nhazi multilayer nke nwere doping dị iche iche ma ọ bụ ihe dị iche iche.

Teknụzụ MBE na-enweta mmụba ugboro ugboro nke akwa epitaxial ultra-thin nwere ọkpụrụkpụ nke otu oyi akwa atomic, na interface dị n'etiti akwa epitaxial dị elu. Ọ na-akwalite uto nke III-V semiconductor na ihe ndị ọzọ dị iche iche nwere ọtụtụ akụkụ. Ka ọ dị ugbu a, usoro MBE aghọwo ngwá ọrụ usoro dị elu maka mmepụta nke ọgbọ ọhụrụ nke ngwa ngwa ngwa ngwa na ngwaọrụ optoelectronic. Ọdịmma nke nkà na ụzụ MBE bụ ihe nkiri na-eto ngwa ngwa, ihe achọrọ dị elu, yana nnukwu akụrụngwa na akụrụngwa eji akwụ ụgwọ.

3.11 Sistemụ Epitaxy nke Vapor

Usoro vapor phase epitaxy (VPE) na-ezo aka na ngwaọrụ uto epitaxial nke na-ebuga ogige gas na mkpụrụ osisi wee nweta otu oyi akwa kristal nwere otu nhazi lattice dị ka mkpụrụ site na mmeghachi omume kemịkalụ. Epitaxial oyi akwa nwere ike ịbụ homoepitaxial oyi akwa (Si / Si) ma ọ bụ heteroepitaxial oyi akwa (SiGe / Si, SiC / Si, GaN / Al2O3, wdg). Ugbu a, a na-eji teknụzụ VPE eme ihe n'ọtụtụ ebe na nkwadebe nanomaterial, ngwaọrụ ike, ngwaọrụ optoelectronic semiconductor, fotovoltaics nke anyanwụ, na sekit jikọtara ọnụ.

Ahụkarị VPE gụnyere ikuku mgbali epitaxy na mbelata nrụgide epitaxy, ultra-high agụụ chemical vapor deposition, metal organic chemical vepor deposition, wdg The isi ihe na VPE technology bụ mmeghachi omume ụlọ imewe, gas eruba mode na uniformity, okpomọkụ uniformity na nkenke akara. njikwa nrụgide na nkwụsi ike, njikwa urughuru na ntụpọ, wdg.

Ka ọ dị ugbu a, ntụzịaka mmepe nke sistemu VPE azụmahịa bụ nnukwu ibu wafer, njikwa akpaka zuru oke, yana nleba anya oge okpomọkụ na usoro uto. Usoro VPE nwere usoro atọ: vetikal, kehoraizin na cylindrical. Ụzọ kpo oku gụnyere ikpo ọkụ na-eguzogide, ikpo ọkụ induction dị elu na ikpo ọkụ infrared.

Ka ọ dị ugbu a, sistemụ VPE na-ejikarị arụ ọrụ diski kwụ ọtọ, nke nwere njiri mara ezigbo ịdị n'otu nke uto ihe nkiri epitaxial na nnukwu ibu wafer. Usoro VPE na-enwekarị akụkụ anọ: reactor, usoro kpo oku, usoro ụzọ gas na usoro nchịkwa. N'ihi na oge uto nke ihe nkiri GaAs na GaN epitaxial dị ogologo, a na-ejikarị kpo oku induction na ikpo ọkụ. Na silicon VPE, nnukwu ihe nkiri epitaxial na-eto eto na-ejikarị ọkụ induction; Mkpa ihe nkiri epitaxial dị mkpa na-ejikarị kpo oku infrared iji nweta ebumnuche nke ịrị elu/ọdịda okpomọkụ ngwa ngwa.

3.12 Sistemụ Epitaxy Oge Liquid

Sistemụ Epitaxy Liquid Phase Epitaxy (LPE) na-ezo aka na akụrụngwa uto epitaxial nke na-agbaze ihe a ga-akụ (dị ka Si, Ga, As, Al, wdg) na dopants (dị ka Zn, Te, Sn, wdg) na a. ígwè nwere ebe mgbaze dị ala (dị ka Ga, In, wdg), nke mere na solute na-ejupụta ma ọ bụ na-ejupụta na ihe mgbaze, mgbe ahụ, a na-akpọtụrụ otu mkpụrụ kristal ahụ. na ngwọta ya, na solute na-ebuli site na ihe mgbaze site na nke nta nke nta na-ajụ oyi, na oyi akwa nke ihe onwunwe kristal nwere ihe nhazi kristal na lattice mgbe niile yiri nke mkpụrụ ahụ na-etolite n'elu nke mkpụrụ.

Nelson et al tụpụtara usoro LPE. na 1963. A na-eji ya na-eto eto Si thin films na otu kristal ihe, yana semiconductor ihe dị ka III-IV otu na mercury cadmium telluride, na a pụrụ iji mee ihe dị iche iche optoelectronic ngwaọrụ, microwave ngwaọrụ, semiconductor ngwaọrụ na anyanwụ cell. .

———————————————————————————————————————————————————————— ————————————-

Semicera nwere ike inyeakụkụ graphite, mmetụta dị nro / siri ike, akụkụ silicon carbide, Akụkụ CVD silicon carbide, naAkụkụ SiC/TaC mkpuchin'ime ụbọchị 30.

Ọ bụrụ na ị nwere mmasị na ngwaahịa semiconductor ndị a,biko egbula oge ịkpọtụrụ anyị na oge mbụ.

Tel: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Oge nzipu: Ọgọst-31-2024