Wafers bụ isi akụrụngwa maka mmepụta nke sekit agbakwunyere, ngwaọrụ semiconductor pụrụ iche na ngwaọrụ ike. A na-eme ihe karịrị 90% nke sekit agbakwunyere na akwa-ọcha, nke dị elu.

Ngwa nkwadebe wafer na-ezo aka na usoro nke ịme ihe silicon polycrystalline dị ọcha n'ime silicon single kristal mkpanaka ihe nke otu dayameta na ogologo, wee tinye silicon otu kristal mkpanaka na usoro nhazi igwe, ọgwụgwọ kemịkalụ na usoro ndị ọzọ.

Akụrụngwa na-arụpụta silicon wafers ma ọ bụ epitaxial silicon wafers nke na-ezute ụfọdụ ziri ezi geometric na mma elu chọrọ ma na-enye mkpụrụ silicon achọrọ maka imepụta mgbawa.

Usoro a na-ahụkarị maka ịkwadebe wafer silicon na dayameta nke na-erughị 200 mm bụ:

Otu kristal uto → mkpọpu → mpụta dayameta na-atụgharị → slicing → chamfering → egweri → etching → gettering → polishing → ihicha → epitaxy → nkwakọ, wdg.

Usoro bụ isi maka ịkwadebe wafer silicon na dayameta nke 300 mm bụ nke a:

Otu kristal na-eto eto → truncation → dayameta mpụta na-agbagharị → slicing → chamfering → ikiri elu → etching → polishing → polishing ihu abụọ → polishing otu akụkụ → nhicha ikpeazụ → epitaxy/annealing → nkwakọ, wdg.

1.Silicon ihe

Silicon bụ ihe semiconductor n'ihi na ọ nwere 4 valence electrons ma nọ na otu IVA nke tebụl oge yana ihe ndị ọzọ.

Ọnụọgụ nke valence eletrọn na silicon na-etinye ya n'etiti ezigbo onye nduzi (1 valence electron) na insulator (8 valence electrons).

Achọghị silicon dị ọcha na okike, a ga-ewepụtarịrị ya ma sachaa ya iji mee ka ọ dị ọcha maka nrụpụta. A na-ahụkarị ya na silica (silicon oxide ma ọ bụ SiO2) na silicates ndị ọzọ.

Ụdị SiO2 ndị ọzọ gụnyere iko, kristal na-enweghị agba, quartz, agate na anya pusi.

Ihe mbụ ejiri mee ihe dị ka semiconductor bụ germanium na 1940s na mmalite 1950s, ma silicon dochie ya ngwa ngwa.

A họọrọ silicon dị ka isi ihe semiconductor maka isi ihe anọ:

Uru nke ihe eji eme silicon: Silicon bụ ihe nke abụọ kachasị ukwuu n'ụwa, na-aza 25% nke eriri ụwa.

Ebe mgbaze dị elu nke ihe silicon na-enye ohere nnabata usoro sara mbara: Ebe mgbaze nke silicon na 1412°C dị elu karịa ebe mgbaze nke germanium na 937°C. Ebe mgbaze dị elu na-enye ohere ka silicon na-eguzogide usoro okpomọkụ dị elu.

Ngwa silicon nwere oke okpomọkụ na-arụ ọrụ sara mbara;

Uto okike nke silicon oxide (SiO2): SiO2 bụ ihe dị elu, ihe mkpuchi ọkụ eletrik kwụsiri ike ma na-eme ihe dị ka ihe mgbochi kemịkalụ magburu onwe ya iji chebe silicon pụọ na mmetọ mpụga. Nkwụsi ike eletrik dị mkpa iji zere ntapu n'etiti ndị nduzi dị n'akụkụ na sekit agbakwunyere. Ikike itolite akwa siri ike nke ihe SiO2 bụ ihe ndabere maka imepụta ngwaọrụ metal-oxide semiconductor (MOS-FET) na-arụ ọrụ dị elu. SiO2 nwere ihe eji arụ ọrụ yiri silicon, na-enye ohere nhazi oke okpomọkụ na-enweghị oke mkpuchi silicon wafer.

2.Nkwadebe Wafer

A na-ebipụ wafers semiconductor site na nnukwu ihe semiconductor. A na-akpọ ihe semiconductor a mkpanaka kristal, nke a na-esi na nnukwu ngọngọ nke polycrystalline na ihe dị n'ime ihe na-adịghị.

Ịgbanwe ngọngọ polycrystalline ka ọ bụrụ nnukwu otu kristal ma nye ya nhazi kristal ziri ezi na ego kwesịrị ekwesị nke ụdị N ma ọ bụ P-ụdị doping ka a na-akpọ uto kristal.

Teknụzụ ndị a na-ahụkarị maka imepụta otu silicon silicon ingots maka nkwadebe silicon wafer bụ usoro Czochralski na usoro agbaze mpaghara.

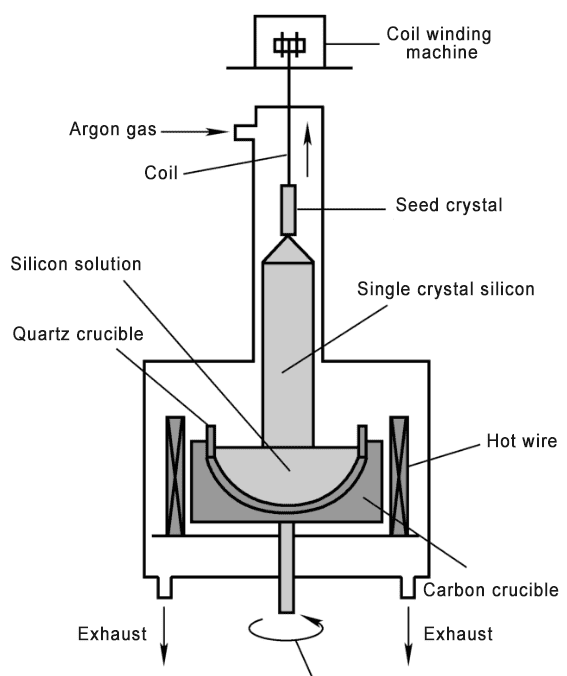

2.1 Usoro Czochralski na Czochralski otu ọkụ kristal

Usoro Czochralski (CZ), nke a makwaara dị ka usoro Czochralski (CZ), na-ezo aka n'usoro nke ịtụgharị mmiri mmiri silicon semiconductor-ọkwa a wụrụ awụ ka ọ bụrụ silicon silicon siri ike nke nwere otu kristal nke nwere ntụgharị kristal ziri ezi ma tinye ya na N-ụdị ma ọ bụ P- ụdị.

Ugbu a, ihe karịrị 85% nke otu silicon kristal na-eto site na iji usoro Czochralski.

Otu ọkụ kristal nke Czochralski na-ezo aka na ngwa usoro nke na-agbaze ihe polysilicon dị ọcha n'ime mmiri mmiri site na kpo oku na ebe nchekwa dị elu mechiri emechi ma ọ bụ ikuku na-adịghị ahụkebe (ma ọ bụ gas na-adịghị ahụkebe), wee megharịa ha ka ha mepụta otu silicon silicon ihe nwere ụfọdụ mpụga. akụkụ.

Ụkpụrụ ọrụ nke otu ọkụ kristal bụ usoro anụ ahụ nke polycrystalline silicon material recrystalizing n'ime otu ihe silicon kristal na ọnọdụ mmiri mmiri.

Enwere ike kewaa CZ otu ọkụ kristal n'ime akụkụ anọ: ahụ ọkụ, usoro nnyefe igwe, usoro ikpo ọkụ na njikwa okpomọkụ, na usoro nnyefe gas.

Ahụ ọkụ na-agụnye oghere ọkụ, axis kristal mkpụrụ, ihe nkedo quartz, ngaji doping, mkpuchi kristal mkpụrụ, na windo nlele.

Oghere ọkụ ahụ bụ iji hụ na okpomọkụ dị na ọkụ na-ekesa nke ọma ma nwee ike ịgbasa okpomọkụ nke ọma; a na-eji osisi kristal mkpụrụ na-ebugharị mkpụrụ kristal ka ọ na-aga elu na ala ma na-atụgharị; A na-etinye ihe ndị na-adịghị ọcha dị mkpa ka a na-etinye doping na ngaji doping;

Ihe mkpuchi kristal mkpụrụ bụ iji chebe kristal mkpụrụ site na mmetọ. A na-ejikarị usoro nnyefe igwe eji achịkwa mmegharị nke kristal mkpụrụ na crucible.

Iji hụ na ihe ngwọta silicon ahụ adịghị oxidized, achọrọ ogo agụụ na ọkụ ọkụ ka ọ dị elu, n'ozuzu n'okpuru 5 Torr, na ịdị ọcha nke gas inert agbakwunyere ga-adị n'elu 99.9999%.

A na-eji otu mpempe silicon kristal nwere ntụzịaka kristal chọrọ dị ka mkpụrụ kristal iji too silicon ingot, na ingot silicon toro eto dị ka oyiri nke kristal mkpụrụ.

Ọnọdụ dị na interface dị n'etiti silicon a wụrụ awụ na otu mkpụrụ kristal kristal kristal kwesịrị ịchịkwa nke ọma. Ọnọdụ ndị a na-eme ka o doo anya na akwa silicon nke dị gịrịgịrị nwere ike ịmegharị nhazi nke mkpụrụ kristal ma mechaa too ka ọ bụrụ nnukwu silicon ingot kristal.

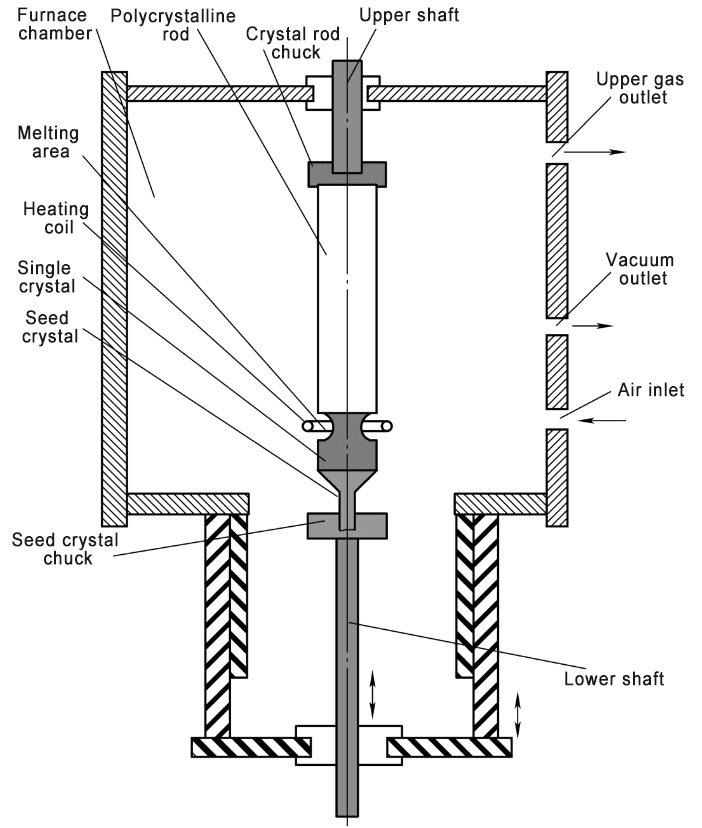

2.2 Usoro mgbaze mpaghara yana otu ọkụ kristal na-agbaze mpaghara

Usoro mpaghara na-ese n'elu mmiri (FZ) na-emepụta otu silicon ingots kristal nwere ọdịnaya oxygen dị ala. Emepụtara usoro mpaghara n'elu mmiri n'afọ ndị 1950 ma nwee ike mepụta silicon kristal kacha dị ọcha ruo taa.

Mpaghara na-agbaze otu ọkụ kristal na-ezo aka na ọkụ nke na-eji ụkpụrụ nke mpaghara na-agbaze na-emepụta mpaghara mgbaze dị warara na mkpanaka polycrystalline site na ebe a na-emechi okpomọkụ dị elu nke polycrystalline mkpara ọkụ ahụ na nnukwu oghere ma ọ bụ obere quartz tube gas. gburugburu ebe nchekwa.

Ngwa usoro nke na-ebugharị mkpanaka polycrystalline ma ọ bụ ahụ ọkụ na-ekpo ọkụ iji mee ka mpaghara agbaze wee jiri nwayọọ nwayọọ mee ka ọ ghọọ otu mkpanaka kristal.

Njirimara nke ịkwadebe otu mkpanaka kristal site na usoro mgbaze mpaghara bụ na enwere ike imeziwanye ịdị ọcha nke mkpanaka polycrystalline n'ime usoro kristal n'ime otu mkpanaka kristal, na uto doping nke ihe mkpanaka bụ otu.

Enwere ike kewaa ụdị mpaghara na-agbaze otu ọkụ kristal ụzọ abụọ: mpaghara na-ese n'elu mmiri na-agbaze otu ọkụ kristal na-adabere na esemokwu elu na mpaghara kwụ ọtọ na-agbaze otu ọkụ kristal. Na ngwa bara uru, mpaghara na-agbaze otu ọkụ kristal na-ejikarị agbaze mpaghara na-ese n'elu mmiri.

Otu ọkụ kristal na-agbaze mpaghara nwere ike ịkwadebe silicon otu kristal kristal dị elu na-adịchaghị ọcha na-enweghị mkpa maka crucible. A na-ejikarị ya iji kwadebe elu-resistivity (> 20kΩ · cm) otu silicon kristal ma mee ka silicon na-agbaze mpaghara dị ọcha. A na-ejikarị ngwaahịa ndị a na-emepụta ngwaọrụ ike pụrụ iche.

Mpaghara na-agbaze otu ọkụ kristal nwere ọnụ ụlọ ọkụ, ogwe dị elu na ogwe ala dị ala (akụkụ nnyefe igwe), mgbanaka mkpanaka kristal, kristal mkpụrụ osisi, igwe na-ekpo ọkụ (ọkụ ọkụ dị elu), ọdụ ụgbọ mmiri gas (ọdụ ụgbọ mmiri), ntinye gas, ebe ikuku elu), wdg.

N'ime ụlọ ọkụ ọkụ, a na-ahazi mgbasa mmiri jụrụ oyi. Ngwunye ala nke elu elu nke otu ọkụ kristal bụ mkpanaka kristal kristal, nke a na-eji na-agbanye mkpanaka polycrystalline; Ngwunye elu nke ogwe ala bụ mkpụrụ osisi kristal, nke a na-eji na-amachi kristal mkpụrụ.

A na-enye ọkụ ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ, a na-emepụtakwa mpaghara mgbaze dị warara na mkpanaka polycrystalline na-amalite site na njedebe ala. N'otu oge ahụ, axes elu na nke ala na-atụgharị ma na-agbada, nke mere na mpaghara agbaze na-egbuke egbuke n'ime otu kristal.

Uru nke mpaghara ahụ na-agbaze otu ọkụ kristal bụ na ọ bụghị naanị na ọ ga-eme ka ịdị ọcha nke otu kristal dị njikere, kamakwa mee ka mkpara doping na-eto eto karịa, na otu mkpanaka kristal nwere ike sachaa site na ọtụtụ usoro.

Ọdịmma nke mpaghara na-agbaze otu ọkụ kristal bụ ọnụ ahịa usoro dị elu na obere dayameta nke otu kristal a kwadebere. Ugbu a, oke dayameta nke otu kristal nwere ike ịkwadebe bụ 200mm.

N'ozuzu elu nke mpaghara agbaze otu kristal ọkụ akụrụngwa dịtụ elu, na strok nke elu na ala axes dịtụ ogologo, otú ogologo otu kristal mkpara nwere ike tolite.

3. Wafer nhazi na akụrụngwa

Mkpanaka kristal kwesịrị ịgafe usoro usoro iji mepụta mkpụrụ osisi silicon nke na-emezu ihe achọrọ nke nrụpụta semiconductor, ya bụ wafer. Isi usoro nhazi bụ:

Tumbling, ịkpụ, slicing, wafer annealing, chamfering, egweri, polishing, ihicha na nkwakọ, wdg.

3.1 Wafer Annealing

N'ime usoro nke polycrystalline silicon na Czochralski silicon, otu silicon silicon nwere oxygen. N'otu oge okpomọkụ, ikuku oxygen dị na otu silicon kristal ga-enye electrons, na oxygen ga-agbanwe ghọọ ndị na-enye oxygen. Eletrọn ndị a ga-ejikọta na adịghị ọcha na silicon wafer ma na-emetụta resistivity nke silicon wafer.

Ọkụ na-ekpo ọkụ: na-ezo aka na ọkụ nke na-ebuli okpomọkụ dị na oven ruo 1000-1200 ° C na hydrogen ma ọ bụ argon gburugburu. Site na ikpo ọkụ na oyi, ikuku oxygen dị n'akụkụ elu nke silicon wafer na-egbu maramara na-agbanwe ma wepụ ya n'elu ya, na-eme ka ikuku oxygen na-ebuli na oyi akwa.

Akụrụngwa na-agbaze micro ntụpọ n'elu silicon wafers, na-ebelata ọnụ ọgụgụ nke adịghị ọcha n'akụkụ elu nke silicon wafers, na-ebelata ntụpọ, na-etolite a dịtụ ọcha ebe n'elu silicon wafers.

A na-akpọkwa ọkụ ọkụ na-ekpo ọkụ ọkụ na-ekpo ọkụ n'ihi oke okpomọkụ ya. Ụlọ ọrụ ahụ na-akpọkwa usoro nkwụsịtụ nke silicon wafer.

E kewara ọkụ silicon wafer annealing n'ime:

- Igwe ọkụ na-ekpo ọkụ kwụ ọtọ;

- Igwe ọkụ na-ekpo ọkụ kwụ ọtọ;

- Igwe ọkụ na-ekpo ọkụ ngwa ngwa.

Isi ihe dị iche n'etiti ọkụ na-ekpo ọkụ kwụ ọtọ na ọkụ na-ekpo ọkụ kwụ ọtọ bụ ntụziaka nhazi nke ụlọ mmeghachi omume.

A na-ahazi ụlọ mmeghachi omume nke ọkụ ọkụ na-ekpo ọkụ kwụ ọtọ, na otu ogbe nke silicon wafers nwere ike ịkwanye n'ime ụlọ mmeghachi omume nke ọkụ ọkụ na-ekpo ọkụ maka ịchacha n'otu oge ahụ. Oge mgbakasị ahụ na-abụkarị nkeji 20 ruo 30, mana ọnụ ụlọ mmeghachi omume chọrọ oge ikpo ọkụ dị ogologo iji ruo okpomọkụ nke usoro mgbakasị ahụ chọrọ.

Usoro nke ọkụ ọkụ na-ekpo ọkụ kwụ ọtọ na-anabatakwa usoro nke n'otu oge na-ebunye batch nke silicon wafers n'ime ụlọ mmeghachi omume nke ọkụ na-ekpo ọkụ maka ọgwụgwọ annealing. Ụlọ mmeghachi omume nwere nhazi nhazi kwụ ọtọ, nke na-enye ohere ka a na-etinye silicon wafers n'ime ụgbọ mmiri quartz na ọnọdụ kwụ ọtọ.

N'otu oge ahụ, ebe ụgbọ mmiri quartz nwere ike ịtụgharị n'ozuzu ya na ụlọ mmeghachi omume, okpomọkụ na-ekpo ọkụ nke ọnụ ụlọ mmeghachi omume bụ otu, okpomọkụ nkesa na silicon wafer bụ otu, na ọ nwere àgwà ọma na-ekpo ọkụ na-egbuke egbuke. Otú ọ dị, ụgwọ usoro nke ọkụ ọkụ na-ekpo ọkụ kwụ ọtọ dị elu karịa nke ọkụ ọkụ na-ekpo ọkụ.

Igwe ọkụ na-ekpo ọkụ ngwa ngwa na-eji oriọna halogen tungsten na-ekpo ọkụ ozugbo na silicon wafer, nke nwere ike nweta ikpo ọkụ ngwa ngwa ma ọ bụ dị jụụ n'ogo 1 ruo 250 ° C/s. Ọnụego ikpo ọkụ ma ọ bụ jụrụ oyi na-adị ngwa karịa nke ọkụ ọkụ ọdịnala. Ọ na-ewe naanị sekọnd ole na ole iji kpoo ọnụ ụlọ mmeghachi omume n'elu 1100°C.

———————————————————————————————————————————————————————— ——

Semicera nwere ike inyeakụkụ graphite,mmetụta dị nro / siri ike,akụkụ silicon carbide, Akụkụ CVD silicon carbide, naAkụkụ SiC/TaC mkpuchina usoro semiconductor zuru oke n'ime ụbọchị 30.

Ọ bụrụ na ị nwere mmasị na ngwaahịa semiconductor ndị a, biko egbula oge ịkpọtụrụ anyị na oge mbụ.

Tel: +86-13373889683

WhatsApp: +86-15957878134

Email: sales01@semi-cera.com

Oge nzipu: Ọgọst-26-2024