Otu anyị si ewepụta usoro nhazi maka ihe ndị SiC bụ ndị a:

1. Nhazi kristal:

Iji X-ray diffraction na-atụgharị kristal ingot. Mgbe a na-eduzi ọkụ X-ray n'ihu kristal achọrọ, akụkụ nke oghere a gbasasịrị na-ekpebi ntụgharị kristal.

2. Na-egweri dayameta dị n'elu:

Otu kristal toro na graphite crucibles na-agafekarị dayameta ọkọlọtọ. Ngwuri dayameta dị n'èzí na-ebelata ha na nha ọkọlọtọ.

3. Ọgwụgwụ ihu egweri:

Mpempe akwụkwọ 4-inch 4H-SiC na-enwekarị ihu abụọ, isi na nke abụọ. Egweri ihu ngwụcha na-emepe akụkụ ndokwa ndị a.

4. Ịwa waya:

Ịwa waya bụ nzọụkwụ dị oke mkpa na nhazi 4H-SiC substrates. Ihe mgbawa na okpuru ala mebiri emebi n'oge ịwa waya na-emetụta usoro ndị na-esote, na-agbatị oge nhazi ma na-akpata ọnwụ ihe. Usoro a na-ahụkarị bụ ịwa osisi ọtụtụ waya na abrasive diamond. A na-eji mmegharị na-emegharị nke wires ọla jikọtara ya na abrasives diamond iji belata ingot 4H-SiC.

5. Na-akpa:

Iji gbochie nchikota ọnụ ma belata mfu ndị a na-eri eri n'oge usoro ndị na-esote, a na-edobe akụkụ dị nkọ nke ibe waya-sawn ka ọ bụrụ ụdị a kapịrị ọnụ.

6. Iri:

Ịwa waya na-ahapụ ọtụtụ ncha na mmebi n'okpuru ala. A na-eme mkparị site na iji wiil diamond wepụ ntụpọ ndị a dị ka o kwere mee.

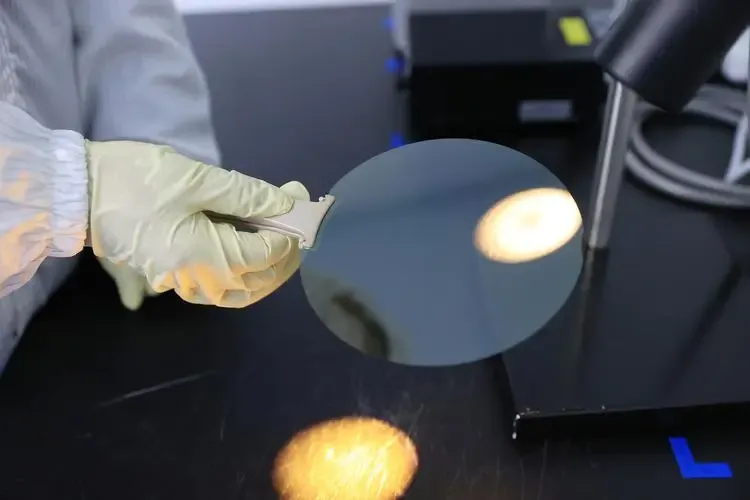

7. Na-egweri:

Usoro a na-agụnye egweri siri ike na nke ọma site na iji boron carbide ma ọ bụ abrasives dị obere na-ewepụ ihe ndị fọdụrụnụ na mmebi ọhụrụ ewepụtara n'oge mkpa.

8. Nchacha:

Nzọụkwụ ikpeazụ gụnyere polishing siri ike na ezigbo polishing site na iji alumina ma ọ bụ silicon oxide abrasives. Mmiri na-egbuke egbuke na-eme ka elu ahụ dị nro, nke a na-ewepụ ya site na abrasives. Nzọụkwụ a na-eme ka ihu dị larịị na nke adịghị emebi emebi.

9. Nhicha:

Na-ewepụ ihe ndị ahụ, ọla, ihe nkiri oxide, ihe ndị dị ndụ na ihe mmetọ ndị ọzọ fọdụrụ na usoro nhazi.

Oge nzipu: Mee-15-2024