Silicon carbide ọkụ tubenwere uru nke ike dị elu, isi ike dị elu, nkwụsi ike dị mma, nkwụsị okpomọkụ dị elu, nkwụsị nke corrosion, nkwụsị ọkụ ọkụ dị mma, nnukwu ikuku okpomọkụ, ezigbo nkwụsị oxidation na ihe ndị ọzọ. A na-ejikarị eme ihe na nkedo ugboro ugboro, ọkụ ọgwụgwọ okpomọkụ dị iche iche, metallurgy, chemical industry, non-ferrous metal forging na ọrụ ndị ọzọ.Silicon carbide ọkụ tubeA na-eji ya eme ihe n'ite ọkụ nchara nchara na ọkụ nkedo ọkụ, yana ogologo ya nwere ike ịhazi dịka mkpa saịtị ahụ siri dị.

Njirimara nkesilicon carbide ọkụ tubes

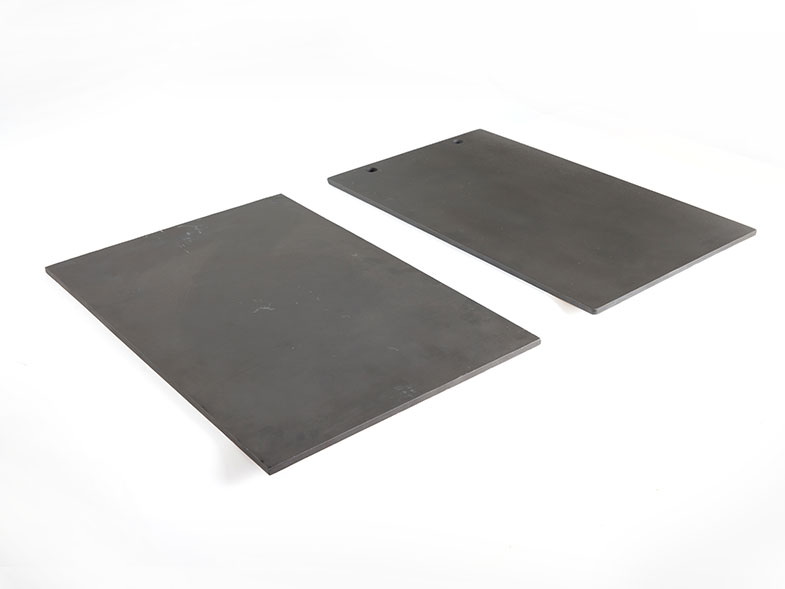

Silicon carbide furnace tube bụ ezigbo ngwaahịa nke silicon carbide sintered na oke okpomọkụ yana silicon carbide dị ka isi akụrụngwa. Ọ nwere uru nke elu okpomọkụ na-eguzogide, corrosion eguzogide, ngwa ngwa thermal conductivity, elu ike, elu ike ike, ezigbo eyi na-eguzogide, ezigbo thermal ujo na-eguzogide, nnukwu thermal conductivity, ezigbo oxidation resistance na na. Ma nsọtụ na-onwem na pụrụ iche elu-okpomọkụ mkpuchi bushings, na corrosion nke metal ngwọta na electric kpo oku ọcha (gụnyere silicon carbide mkpanaka, electric oku waya waya, wdg) nwere ike n'ụzọ dị irè zere, na egosi dị mma karịa ụdị ọ bụla nke graphite ngwaahịa. . The silicon carbide furnace tube nwere thermal conductivity, oxidation resistance, thermal shock resistance, elu okpomọkụ na-eguzogide, ezigbo kemịkalụ nkwụsi ike, ike acid na-eguzogide, dịghị mmeghachi omume na ike acid na alkali.

Silicon carbide ọkụ tubemmepụta teknụzụ: emechara ngwaahịa na-ewere silicon carbide dị ka isi akụrụngwa, na bụ ihe magburu onwe silicon carbide okokụre ngwaahịa chụọ n'ọrụ site pụrụ iche technology na elu okpomọkụ. Enwere ike ịhazi ọkọlọtọ ogologo dịka mkpa ndị ahịa si dị. The isi ojiji nke silicon carbide ọkụ tube: ọtụtụ-eji na-abụghị ferrous metal ọzụzụ, aluminum ngwaahịa degasing usoro, obibi na dyeing ígwè, zinc na aluminum ọzụzụ na okokụre ngwaahịa nhazi.

Mmepe ụlọ ọrụ nke silicon carbide

Silicon carbide nwere njirimara nke mgbochi ntinye dị elu, mkpọtụ dị ala, ezi linearity, wdg, bụ otu n'ime ngwa ngwa silicon carbide na-eto ngwa ngwa, na nke mbụ nwetara azụmahịa. E jiri ya tụnyere MOSFET, ọ nweghị nsogbu ntụkwasị obi na-akpata site na ntụpọ oxide ọnụ ụzọ ámá yana njedebe ngagharị dị ala, yana njirimara ọrụ ya na-arụ ọrụ na-ejigide ikike ịrụ ọrụ ugboro ugboro. Ke adianade do, silicon carbide junction Ọdịdị nwere mma kwụsie ike na ntụkwasị obi na elu okpomọkụ nke mere na ọnụ ụzọ voltaji na-emekarị adịghị mma, ya bụ, na-emekarị na-emeghe ngwaọrụ, nke bụ nnọọ adịghị mma maka ike ngwá electronic ngwa, na-adịghị dakọtara na ugbu a nkịtị nkịtị. sekit mbanye. Site na iwebata teknụzụ nke ngwaọrụ injection groove, a na-emepụta ngwaọrụ emelitere n'okpuru steeti adịghị anya. Otú ọ dị, a na-emepụta ngwaọrụ ndị a na-emewanyewanye na-akwụ ụgwọ nke ụfọdụ àgwà ndị dị mma na-eguzogide, ya mere na-emeghe (ụdị nkwụsịtụ) dị mfe iji nweta njupụta ike dị elu na ikike dị ugbu a, na ụdị nkwụsịtụ nwere ike nweta site na cascading na-emekarị ka ọ kwụsị ọrụ. A na-emejuputa usoro cascade site na usoro MOSFET nke nwere silicon dị ala. The cascaded mbanye sekit bụ ndakọrịta ndammana na izugbe nzube silicon ngwaọrụ mbanye sekit. Nke a cascade Ọdịdị dị nnọọ mma maka dochie mbụ silicon na elu voltaji na elu oge oge, na-ezere ozugbo nsogbu ndakọrịta nke mbanye sekit.

Oge nzipu: Sep-25-2023