Kedu ihe bụ mkpuchi silicon Carbide SiC?

Mkpuchi Silicon Carbide (SiC) bụ teknụzụ mgbanwe mgbanwe nke na-enye nchebe pụrụ iche na arụmọrụ na gburugburu oke okpomọkụ na gburugburu kemịkalụ. A na-etinye mkpuchi a dị elu na ihe dị iche iche, gụnyere graphite, ceramics, na metals, iji kwalite ihe onwunwe ha, na-enye nchebe dị elu megide corrosion, oxidation, na eyi. Ngwongwo pụrụ iche nke mkpuchi SiC, gụnyere ịdị ọcha ha dị elu, ezigbo conductivity thermal, na iguzosi ike n'ezi ihe, na-eme ka ha dị mma maka iji ya na ụlọ ọrụ ndị dị ka mmepụta semiconductor, ikuku ikuku, na teknụzụ ọkụ ọkụ dị elu.

Uru nke mkpuchi silicon carbide

Mkpuchi SiC na-enye ọtụtụ uru isi na-ekewapụ ya na mkpuchi nchekwa ọdịnala:

- -Njupụta dị elu & nguzogide corrosion

- Ihe owuwu SiC nke cubic na-eme ka mkpuchi njupụta dị elu, na-emewanye nguzogide corrosion na ịgbatị ogologo ndụ akụrụngwa.

- -Mkpuchi pụrụiche nke ụdị mgbagwoju anya

- A ma ama SiC mkpuchi maka mkpuchi ya dị oke mma, ọbụlagodi na obere oghere ndị kpuru ìsì nwere omimi ruru 5 mm, na-enye ọkpụrụkpụ otu agba ruo 30% n'ebe kachasị omimi.

- -Ike n'elu ala nwere ike ịhazi ya

- Usoro mkpuchi ahụ na-agbanwe agbanwe, na-enye ohere maka ịdị iche iche dị n'elu iji kwado ihe ngwa ngwa chọrọ.

- -Elu ịdị ọcha mkpuchi

- Enwetara ya site na iji gas dị ọcha dị elu, mkpuchi SiC na-anọgide na-adị ọcha, yana ọkwa adịghị ọcha na-adịkarị n'okpuru 5 ppm. Ịdị ọcha a dị mkpa maka ụlọ ọrụ teknụzụ dị elu nke chọrọ nkenke na mmetọ dị ntakịrị.

- -Thermal kwụsie ike

- Ihe mkpuchi seramiiki nke silicon carbide nwere ike iguzogide oke okpomọkụ, yana oke ọrụ na-arụ ọrụ ruo 1600 Celsius C, na-eme ka ntụkwasị obi na gburugburu ebe okpomọkụ dị elu.

Ngwa nke mkpuchi SiC

A na-eji mkpuchi SiC eme ihe n'ofe ụlọ ọrụ dị iche iche maka arụmọrụ na-enweghị atụ na gburugburu ebe ịma aka. Ngwa igodo gụnyere:

- -LED & ụlọ ọrụ anyanwụ

- A na-ejikwa ihe mkpuchi maka ihe ndị dị na LED na cell cell n'ichepụta, ebe ịdị ọcha dị elu na nguzogide okpomọkụ dị mkpa.

- - Teknụzụ ikpo ọkụ dị elu

- A na-eji graphite mkpuchi SiC na ihe ndị ọzọ arụ ọrụ na ihe ndị na-ekpo ọkụ maka ọkụ na reactors ejiri na usoro mmepụta ihe dị iche iche.

- -Semiconductor Crystal Growth

- N'ime uto kristal semiconductor, a na-eji mkpuchi SiC kpuchido ihe ndị na-etinye aka na uto nke silicon na kristal semiconductor ndị ọzọ, na-enye nguzogide corrosion dị elu na nkwụsi ike ọkụ.

- - Silicon na SiC Epitaxy

- A na-etinye mkpuchi SiC na ihe ndị dị na usoro uto epitaxial nke silicon na silicon carbide (SiC). Ihe mkpuchi ndị a na-egbochi oxidation, mmetọ, ma hụ na ịdị mma nke epitaxial layers, nke dị mkpa maka mmepụta nke ngwaọrụ semiconductor dị elu.

- -Oxidation na mgbasa usoro

- A na-eji ihe mkpuchi SiC mee ihe na oxidation na usoro mgbasa ozi, ebe ha na-enye ihe mgbochi dị irè megide adịghị ọcha na-achọghị ma kwalite iguzosi ike n'ezi ihe nke ngwaahịa ikpeazụ. Ihe mkpuchi ahụ na-eme ka ogologo ndụ dịkwuo ogologo na ntụkwasị obi nke ihe ndị a na-ekpughe na oxidation dị elu ma ọ bụ usoro mgbasa ozi.

Njirimara igodo nke mkpuchi SiC

Ihe mkpuchi SiC na-enye akụrụngwa dị iche iche na-eme ka arụmọrụ na ịdịte aka nke ihe mkpuchi sic dị:

- -Crystal Structure

- A na-emepụta ihe mkpuchi ahụ na aβ 3C (cubic) kristalỌdịdị, nke bụ isotropic ma na-enye nchebe corrosion kacha mma.

- -Njupụta na porosity

- Ihe mkpuchi SiC nwere njupụta nke3200 kg/m³na ngosi0% porosity, n'ịhụ na helium na-arụ ọrụ siri ike na nkwụsị nke corrosion dị irè.

- - Thermal na Electric Njirimara

- Ihe mkpuchi SiC nwere ihe nrụpụta thermal dị elu(200 W/m·K)na mma eletriki resistivity(1MΩ·m), na-eme ka ọ dị mma maka ngwa ndị chọrọ nlekọta okpomọkụ na mkpuchi eletrik.

- -Mechanical Ike

- Na ihe na-agbanwe modul nke450 GPA, SiC mkpuchi na-enye elu n'ibu ike, na-eme ka structural iguzosi ike n'ezi ihe nke components.

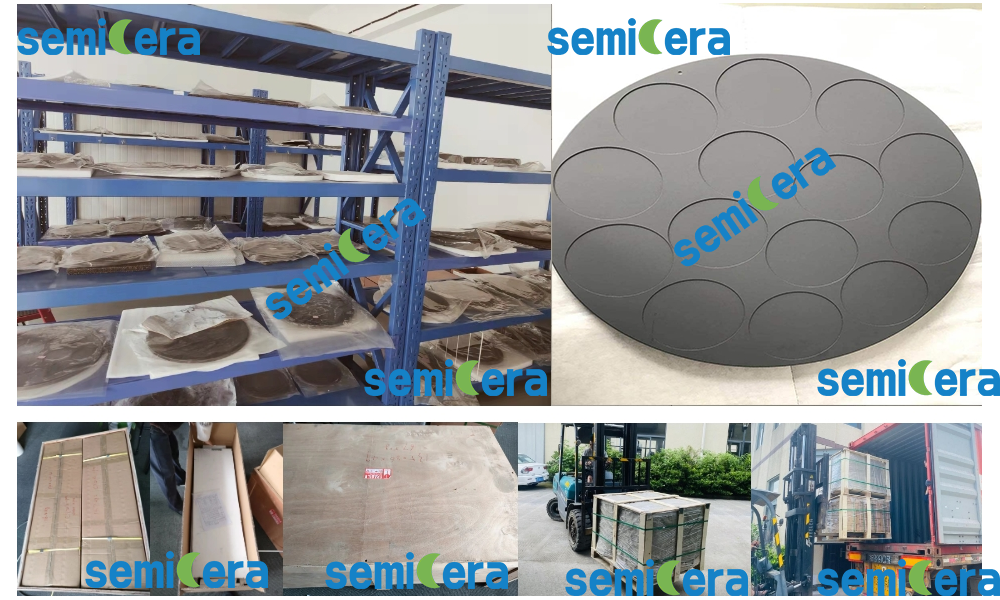

Usoro mkpuchi silicon carbide SiC

A na-etinye mkpuchi SiC site na Ndobe Mmiri Vapor (CVD), usoro na-agụnye ire ere ikuku nke gas iji tinye akwa SiC dị nro na mkpụrụ. Usoro nkwụnye ego a na-enye ohere maka oke uto na njikwa ziri ezi n'elu ọkpụrụkpụ oyi akwa, nke nwere ike ịmalite10 μm ruo 500 µm, dabere na ngwa. Usoro mkpuchi ahụ na-ahụkwa na mkpuchi otu, ọbụlagodi na geometries dị mgbagwoju anya dị ka obere oghere ma ọ bụ nke miri emi, nke na-esirikarị ike maka ụzọ mkpuchi ọdịnala.

Akụrụngwa dabara adaba maka mkpuchi SiC

Enwere ike itinye mkpuchi SiC n'ọtụtụ ihe, gụnyere:

- - Graphite na Carbon Composites

- Graphite bụ ihe na-ewu ewu maka mkpuchi SiC n'ihi ọmarịcha ọkụ na ọkụ eletrik. Mkpuchi SiC na-abanye n'ụdị porous nke graphite, na-eke njikọ emelitere yana inye nchebe dị elu.

- -Seramik

- Ceramics dabeere na silicon dị ka SiC, SiSiC, na RSiC na-erite uru site na mkpuchi SiC, nke na-eme ka nkwụsị nke corrosion ha dịkwuo mma ma gbochie mgbasa nke adịghị ọcha.

Kedu ihe kpatara ịhọrọ mkpuchi SiC?

Ihe mkpuchi dị n'elu na-enye ihe ngwọta dị mma na nke bara uru maka ụlọ ọrụ na-achọ ịdị ọcha dị elu, nkwụsị nke corrosion, na nkwụsi ike okpomọkụ. Ma ị na-arụ ọrụ na semiconductor, aerospace, ma ọ bụ ngalaba kpo oku na-arụ ọrụ dị elu, mkpuchi SiC na-enye nchebe na arụmọrụ ịchọrọ iji nọgide na-arụ ọrụ nke ọma. Nchikota nke ihe owuwu cubic nwere njupụta dị elu, ihe ndị a na-emezigharị n'elu, na ikike nke mkpuchi geometries dị mgbagwoju anya na-eme ka a mata na ihe ndị nwere mkpuchi sic nwere ike iguzogide ọbụna gburugburu ebe ndị siri ike.

Maka ozi ndị ọzọ ma ọ bụ kparịta ka mkpuchi seramiiki silicon carbide nwere ike isi baara ngwa gị uru, bikokpọtụrụ anyị.

Oge nzipu: Ọgọst-12-2024