Silicon nitride (Si₃N₄) seramiiki, dị ka seramiiki ihe owuwu dị elu, nwere ihe ndị mara mma dị ka nguzogide okpomọkụ dị elu, ike dị elu, isi ike dị elu, ike siri ike, nguzogide na-akpụ akpụ, nguzogide oxidation, na iyi nguzogide. Na mgbakwunye, ha na-enye ezigbo nguzogide ujo ọkụ, akụrụngwa dielectric, ịdị elu thermal conductivity, yana ọmarịcha ọrụ nnyefe ọkụ eletrik dị elu. Ngwongwo ndị a pụtara ìhè na-eme ka a na-eji ya eme ihe n'ọtụtụ ebe n'ime ihe nhazi dị mgbagwoju anya, karịsịa na mbara igwe na mpaghara ndị ọzọ dị elu.

Otú ọ dị, Si₃N₄, ịbụ a compound na siri ike covalent agbụ, nwere a kwụsiri ike Ọdịdị nke na-eme sintering na elu njupụta siri ike site siri ike-ala mgbasa naanị. Iji kwalite sintering, sintering enyemaka, dị ka metal oxides (MgO, CaO, Al₂O₃) na obere earth oxides (Yb₂O₃, Y₂O₃, Lu₂O₃, CeO₂), na-agbakwunyere na-kwado densification site a mmiri mmiri-phase sintering usoro.

Ugbu a, nkà na ụzụ ngwaọrụ semiconductor zuru ụwa ọnụ na-aga n'ihu na voltaji dị elu, nnukwu mmiri iyi, na njupụta ike ka ukwuu. Nnyocha n'ime ụzọ maka imepụta ceramik Si₃N₄ dị ukwuu. Edemede a na-ewebata usoro ịgbakọ nke ọma na-emeziwanye njupụta na akụrụngwa akụrụngwa nke seramiki silicon nitride.

Ụzọ Sintering nkịtị maka Si₃N₄ ceramics

Ntụle nke arụmọrụ maka Si₃N₄ ceramics akwadoro site na ụzọ Sintering dị iche iche.

1. Sintering na-emeghachi omume (RS):Sintering na-emeghachi omume bụ ụzọ mbụ eji akwadebe ihe nrụpụta Si₃N₄ ceramik. Ọ dị mfe, dị ọnụ ahịa, ma nwee ike ịmepụta ụdị mgbagwoju anya. Otú ọ dị, ọ nwere ogologo usoro mmepụta ihe, nke na-adịghị eme ka mmepụta ihe mmepụta ihe.

2. Sintering enweghị nrụgide (PLS):Nke a bụ usoro nhịahụ kacha dị mfe ma dị mfe. Agbanyeghị, ọ na-achọ akụrụngwa Si₃N₄ dị elu ma na-ebutekarị ceramik nwere njupụta dị ala, mbelata dị ukwuu, yana ọchịchọ ịgbawa ma ọ bụ ngbanwe.

3. Ịkpọ oku na-ekpo ọkụ (HP):Ngwa nke uniaxial n'ibu nrụgide na-abawanye ike ịkwọ ụgbọala maka sintering, na-ekwe ka a na-emepụta ceramik dị oke na okpomọkụ 100-200 ° C dị ala karịa nke ejiri na-enweghị nrụgide. A na-ejikarị usoro a maka imepụta seramiki dị ka ngọngọ dị mfe mana ọ na-esiri ike iru oke na ụdị a chọrọ maka ihe mkpụrụ.

4. Spark Plasma Sintering (SPS):A na-eji SPS mara ngwa ngwa, nchacha ọka, na mbelata okpomoku na-ebelata. Agbanyeghị, SPS chọrọ itinye ego dị ukwuu na akụrụngwa, yana nkwadebe nke nrụpụta ọkụ dị elu Si₃N₄ ceramics site na SPS ka nọ na nnwale nnwale na emebebeghị ya.

5. Nrụgide gas-nrụgide (GPS):Site n'itinye nrụgide gas, usoro a na-egbochi mmebi seramiiki na ọnwụ dị arọ na okpomọkụ dị elu. Ọ dị mfe ịmepụta ceramics dị elu ma mee ka mmepụta ogbe mee ihe. Otú ọ dị, otu nzọụkwụ gas-nrụgide usoro sintering na-agbasi mbọ ike imepụta ihe nhazi nke nwere otu agba n'ime na mpụga na nhazi. Iji usoro ụzọ abụọ ma ọ bụ ọtụtụ nzọụkwụ nwere ike ibelata ọdịnaya oxygen intergranular nke ukwuu, melite conductivity thermal, ma welie ihe niile.

Otú ọ dị, okpomọkụ dị elu nke ikuku gas-nrụgide ụzọ abụọ emeela nchọpụta gara aga na-elekwasị anya karịsịa n'ịkwadebe Si₃N₄ ceramic substrates na nnukwu okpomọkụ okpomọkụ na ike na-ehulata ọnụ ụlọ. Nnyocha na ceramik Si₃N₄ nwere akụrụngwa akụrụngwa zuru oke yana akụrụngwa igwe dị elu nwere oke oke.

Usoro nrịba gas-nzọụkwụ abụọ maka s₃N₄

Yang Zhou na ndị ọrụ ibe si na Chongqing University of Technology ji usoro enyemaka sintering nke 5 wt.% Yb₂O₃ + 5 wt.% Al₂O₃ iji kwadebe Si₃N₄ ceramics na-eji ma otu nzọụkwụ na abụọ-nzọụkwụ gas-nrụgide usoro sintering na 1800C. Ihe seramiki Si₃N₄ nke usoro nrịbama nke ụzọ abụọ a na-emepụta nwere njupụta dị elu yana akụrụngwa akụrụngwa zuru oke. Ihe na-esonụ na-achịkọta mmetụta nke otu nzọụkwụ na nzọụkwụ abụọ gas-nrụgide sintering Filiks na microstructure na n'ibu Njirimara nke Si₃N₄ seramiiki components.

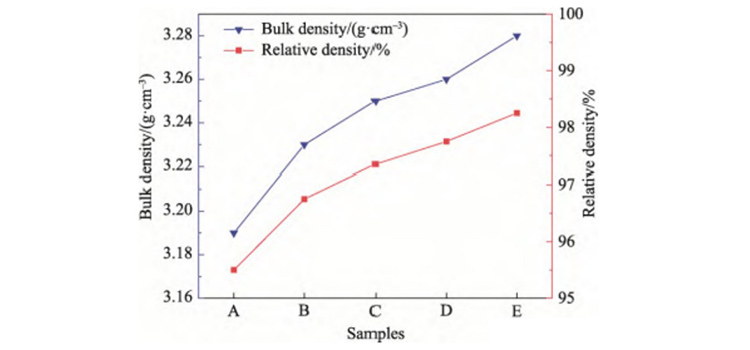

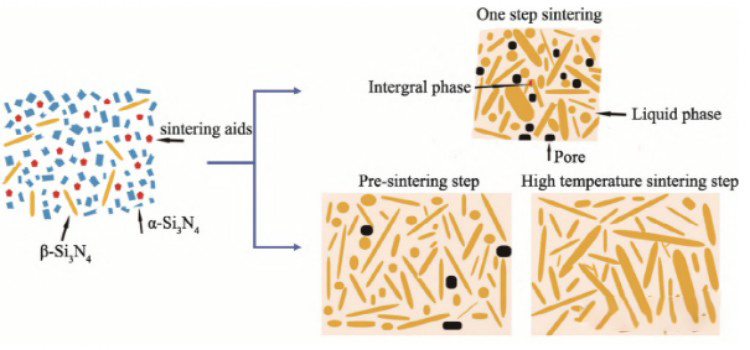

Njupụta Usoro njupụta nke Si₃N₄ na-agụnyekarị usoro atọ, yana ndakọrịta n'etiti ọkwa. Ogbo nke mbụ, nhazigharị urughuru, na nke abụọ, mgbasa-mmiri mmiri, bụ ọkwa kachasị mkpa maka njupụta. Oge mmeghachi omume zuru oke na ọkwa ndị a na-eme ka njupụta nlele dịkwuo mma. Mgbe a na-edozi ọnọdụ okpomọkụ tupu nkewa maka usoro nkwụsị nke nzọụkwụ abụọ na 1600 ° C, β-Si₃N₄ ọka na-etolite ma mepụta pores mechiri emechi. Mgbe tupu singing, ọzọ kpo oku n'okpuru elu okpomọkụ na nitrogen mgbali na-akwalite mmiri mmiri-phase eruba na ndochi, nke na-enyere aka kpochapụ mechiri emechi pores, na-eme ka njupụta nke Si₃N₄ ceramics. Ya mere, ihe atụ ndị a na-emepụta site na usoro nkwụsị nke nzọụkwụ abụọ na-egosi njupụta dị elu na njupụta dị elu karịa nke a na-emepụta site na otu nzọụkwụ.

Usoro na Microstructure N'ime otu nzọụkwụ sintering, oge dị maka nhazigharị urughuru na mgbasa oke ọka nwere oke. N'ime usoro nkwụsị nke nzọụkwụ abụọ, a na-eme nzọụkwụ mbụ na obere okpomọkụ na obere ikuku gas, nke na-agbatị oge nhazigharị ihe na-eme ka mkpụrụ buru ibu. A na-abawanye okpomọkụ ruo n'ogo dị elu, ebe ọka na-aga n'ihu na-eto eto site na usoro nhazi nke Ostwald, na-enye nnukwu njupụta Si₃N₄ ceramics.

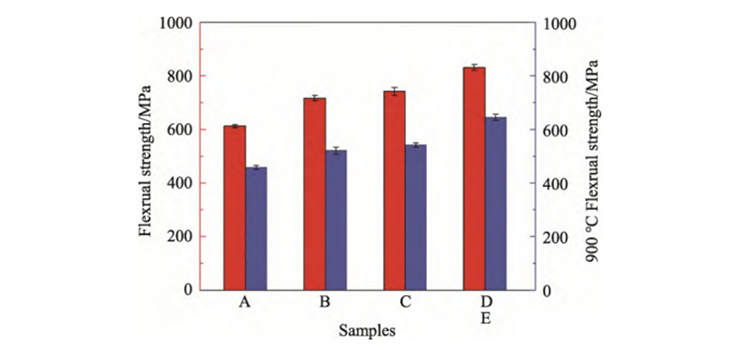

Ngwongwo Mechanical Ịdị nro nke akụkụ intergranular na oke okpomọkụ bụ isi ihe kpatara ike belata. N'ime otu nzọụkwụ na-agba ọsọ, uto ọka na-adịghị mma na-emepụta obere pores n'etiti ọka, nke na-egbochi ọganihu dị ukwuu na ike okpomọkụ. Otú ọ dị, n'ime usoro nkwụsị nke nzọụkwụ abụọ, akụkụ iko ahụ, nke a na-ekesa n'otu n'otu na oke ọka, na mkpụrụ osisi ndị a na-ejikọta ọnụ na-eme ka ike intergranular dịkwuo elu, na-eme ka ike na-ehulata dị elu dị elu.

Na mmechi, ogologo njide n'oge otu nzọụkwụ sintering nwere ike n'ụzọ dị irè ibelata esịtidem porosity na nweta otu esịtidem agba na Ọdịdị ma nwere ike iduga na-adịghị mma ọka ito, nke na-eweda ụfọdụ n'ibu Njirimara. Site n'iji usoro sintering nke ụzọ abụọ-iji obere okpomọkụ tupu ịgbatị oge ịgbatị oge nhazi ihe na oke okpomọkụ iji kwalite uto ọka - Si₃N₄ seramiiki na njupụta nke 98.25%, microstructure edo, na ezigbo ihe eji arụ ọrụ zuru oke. enwere ike ịkwado nke ọma.

| Aha | Mkpụrụ | Ngwakọta oyi akwa epitaxial | Usoro epitaxial | Epitaxial ọkara |

| Silicon homoepitaxial | Si | Si | Uzuoku Phase Epitaxy (VPE) | SiCl4+H2 |

| Silicon heteroepitaxial | Sapphire ma ọ bụ spinel | Si | Uzuoku Phase Epitaxy (VPE) | SiH₄+H₂ |

| GaAs homoepitaxial | GaAs | GaAs GaAs | Uzuoku Phase Epitaxy (VPE) | AsCl₃+Ga+H₂ (Ar) |

| GaAs | GaAs GaAs | Epitaxy Molecular Beam (MBE) | Ga+ As | |

| GaAs heteroepitaxial | GaAs GaAs | GaAlAs/GaAs/GaAlAs | Epitaxy nke mmiri mmiri (LPE) Oge uzuoku (VPE) | Ga+Al+CaAs+ H2 Ga+ASH3+ PH3+CHl+H2 |

| GaP homoepitaxial | GaP | GaP (GaP; N) | Epitaxy nke mmiri mmiri (LPE) Epitaxy nke mmiri mmiri (LPE) | Ga+GaP+H2+ (NH3) Ga+GaAs+GaP+NH3 |

| Superlatice | GaAs | GaAlAs/GaAs ( okirikiri) | Epitaxy Molecular Beam (MBE) MOCVD | Ca, As, Al GaR₃+AlR3+AsH3+H2 |

| InP homoepitaxial | InP | InP | Uzuoku Phase Epitaxy (VPE) Epitaxy nke mmiri mmiri (LPE) | PCl3+In+H2 Na+InAs+GaAs+InP+H₂ |

| Si/GaAs Epitaxy | Si | GaAs | Epitaxy Molecular Beam (MBE) MOGVD | Ga, dị ka GaR₃+ASH₃+H₂ |

Oge nzipu: Dec-24-2024