Nkọwa

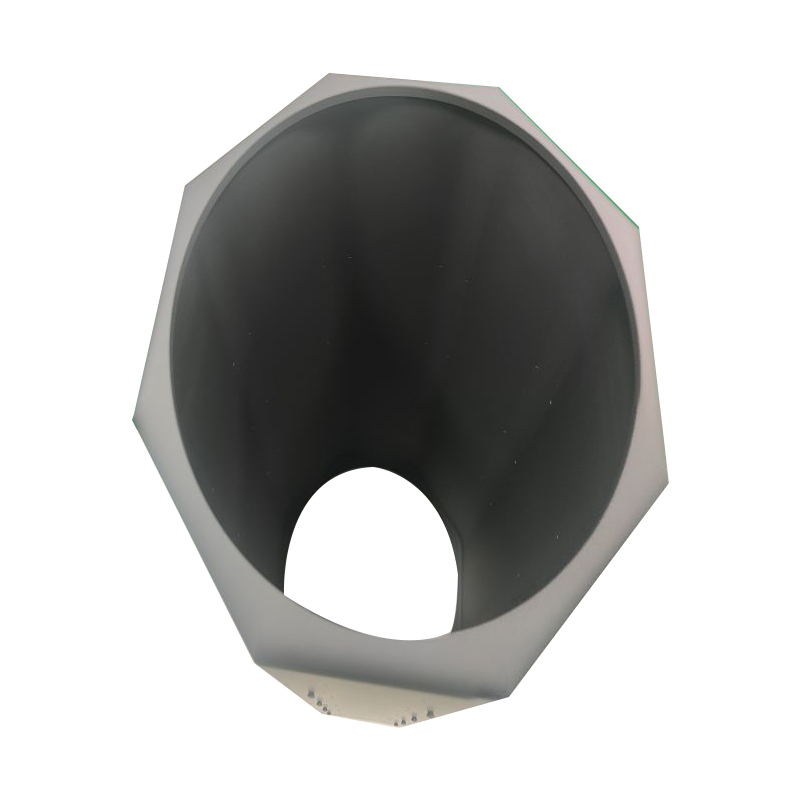

Ụlọ ọrụ anyị na-enyemkpuchi SiCusoro ọrụ n'elu graphite, ceramics na ihe ndị ọzọ site CVD usoro, nke mere na pụrụ iche gas nwere carbon na silicon nwere ike meghachi omume na elu okpomọkụ iji nweta elu-ọcha Sic ụmụ irighiri, nke nwere ike na-edebe n'elu nke mkpuchi ihe na-etolite a.oyi akwa mkpuchi SiCmaka epitaxy barel ụdị hy pnotic.

Isi atụmatụ

1. Nguzogide oxidation dị elu:

Nguzogide oxidation ka dị ezigbo mma mgbe okpomọkụ dị elu dị ka 1600 C.

2. Nnukwu ịdị ọcha: nke a na-eme site na ntinye ikuku kemịkalụ n'okpuru ọnọdụ chlorination dị elu.

3. Nguzogide nbibi: elu ike, kọmpat elu, ezigbo ahụ.

4. Nguzogide corrosion: acid, alkali, nnu na organic reagents.

Nkọwa isi nke mkpuchi CVD-SIC

| Njirimara SiC-CVD | ||

| Ọdịdị kristal | FCC β oge | |

| Njupụta | g/cm ³ | 3.21 |

| Isi ike | Vickers isi ike | 2500 |

| Nha ọka | μm | 2 ~ 10 |

| Ịdị ọcha kemịkalụ | % | 99,99995 |

| Ike ikpo ọkụ | J·kg-1 · K-1 | 640 |

| Sublimation okpomọkụ | ℃ | 2700 |

| Ike Felexural | MPa (RT 4-isi) | 415 |

| Modul nke Young | GPA (4pt gbagọọ, 1300 ℃) | 430 |

| Mgbasawanye okpomọkụ (CTE) | 10-6K-1 | 4.5 |

| Thermal conductivity | (W/mK) | 300 |