Tantalum carbide (TaC)bụ a ibu-elu okpomọkụ na-eguzogide ọgwụ seramiiki ihe na uru nke elu agbaze ebe, elu hardness, ezi chemical kwụsie ike, ike eletriki na thermal conductivity, wdg Ya mere,Mkpuchi TaCenwere ike iji ya dị ka mkpuchi na-eguzogide ablation, mkpuchi na-eguzogide oxidation, na mkpuchi na-eguzogide ọgwụ, a na-ejikwa ya na nchebe ikuku nke ikuku, ọgbọ nke atọ semiconductor otu kristal kristal, ike electronics na ubi ndị ọzọ.

Usoro:

Tantalum carbide (TaC)bụ ụdị ultra-elu okpomọkụ na-eguzogide ihe seramiiki na uru nke elu agbaze ebe, elu ike ike, ezi kemịkal kwụsie ike, ike eletriki na thermal conductivity. Ya mere,Mkpuchi TaCenwere ike iji ya dị ka mkpuchi na-eguzogide ablation, mkpuchi na-eguzogide oxidation, na mkpuchi na-eguzogide ọgwụ, a na-ejikwa ya na nchebe ikuku nke ikuku, ọgbọ nke atọ semiconductor otu kristal kristal, ike electronics na ubi ndị ọzọ.

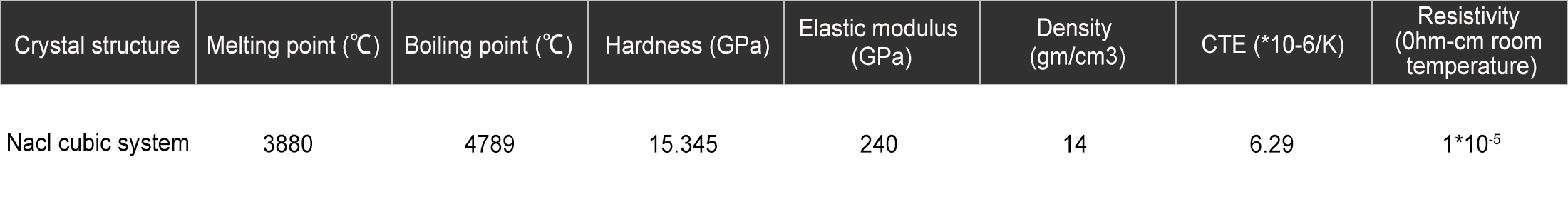

Njirimara dị n'ime mkpuchi mkpuchi:

Anyị na-eji usoro slurry-sintering kwadebeIhe mkpuchi TaCnke ọkpụrụkpụ dị iche iche na mkpụrụ graphite nke nha dị iche iche. Nke mbụ, ntụ ntụ dị elu nke nwere isi Ta na isi iyi C na-ahazi ya na onye na-ekesa na ihe nkedo iji mepụta otu ma kwụsie ike precursor slurry. N'otu oge ahụ, dị ka size nke graphite akụkụ na ọkpụrụkpụ chọrọ nkeMkpuchi TaC, A na-akwadebe ihe mkpuchi ahụ site n'ịgba mmiri, ịwụ, ntinye na ụdị ndị ọzọ. N'ikpeazụ, a na-ekpo ọkụ n'elu 2200 ℃ na oghere na gburugburu ebe obibi iji kwadebe otu uwe, oke, otu oge, na nke ọma-crystalline.Mkpuchi TaC.

Njirimara dị n'ime mkpuchi mkpuchi:

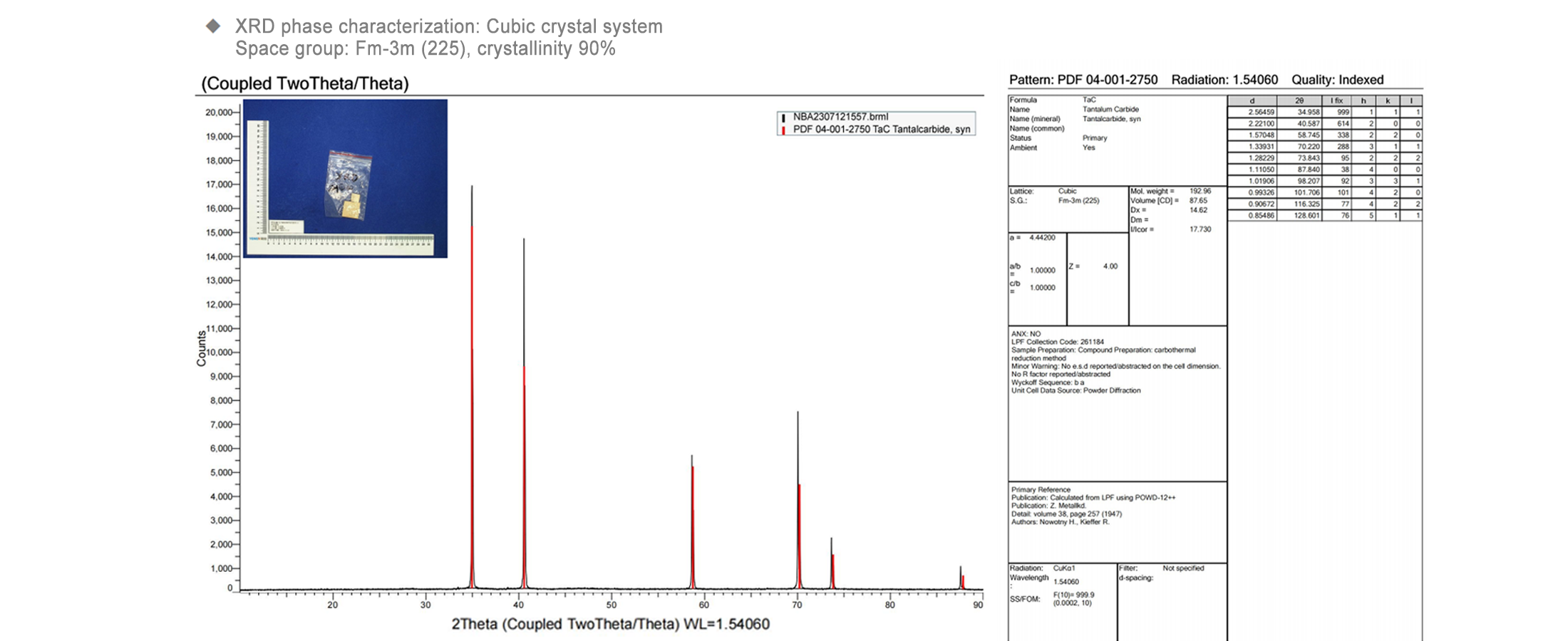

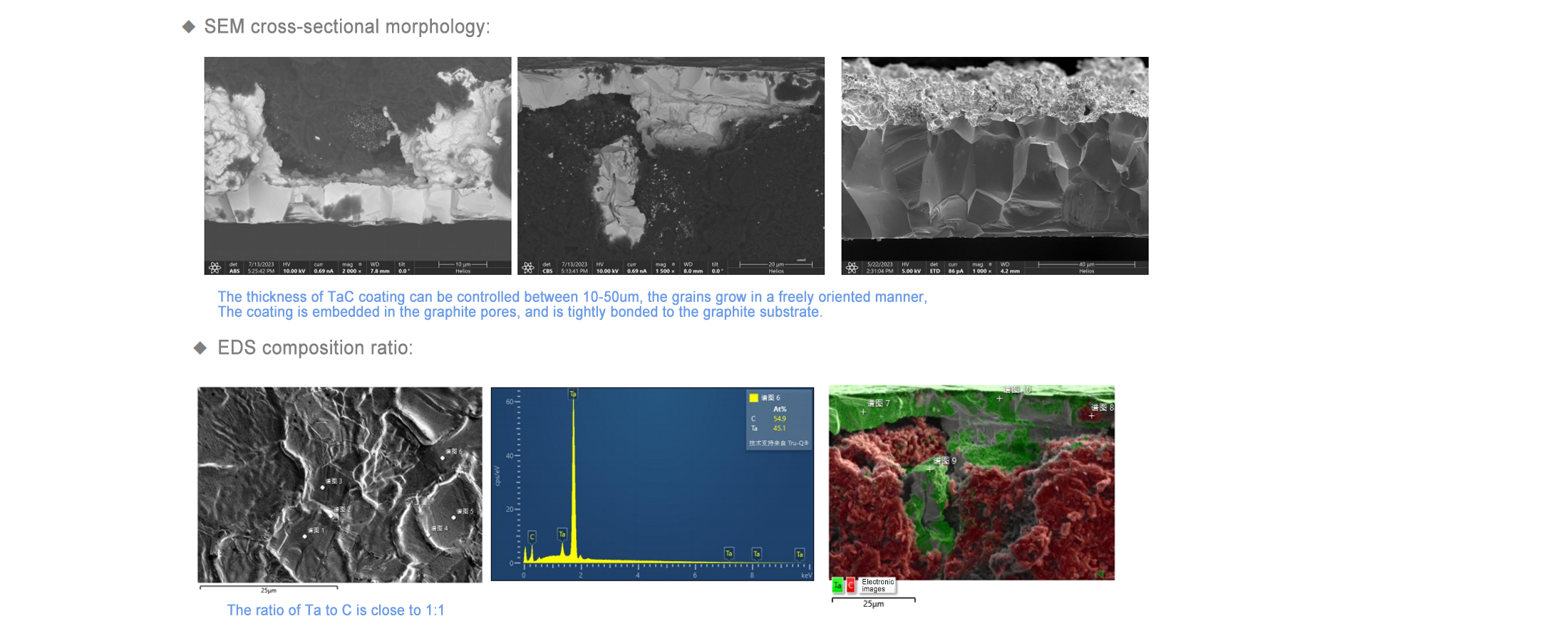

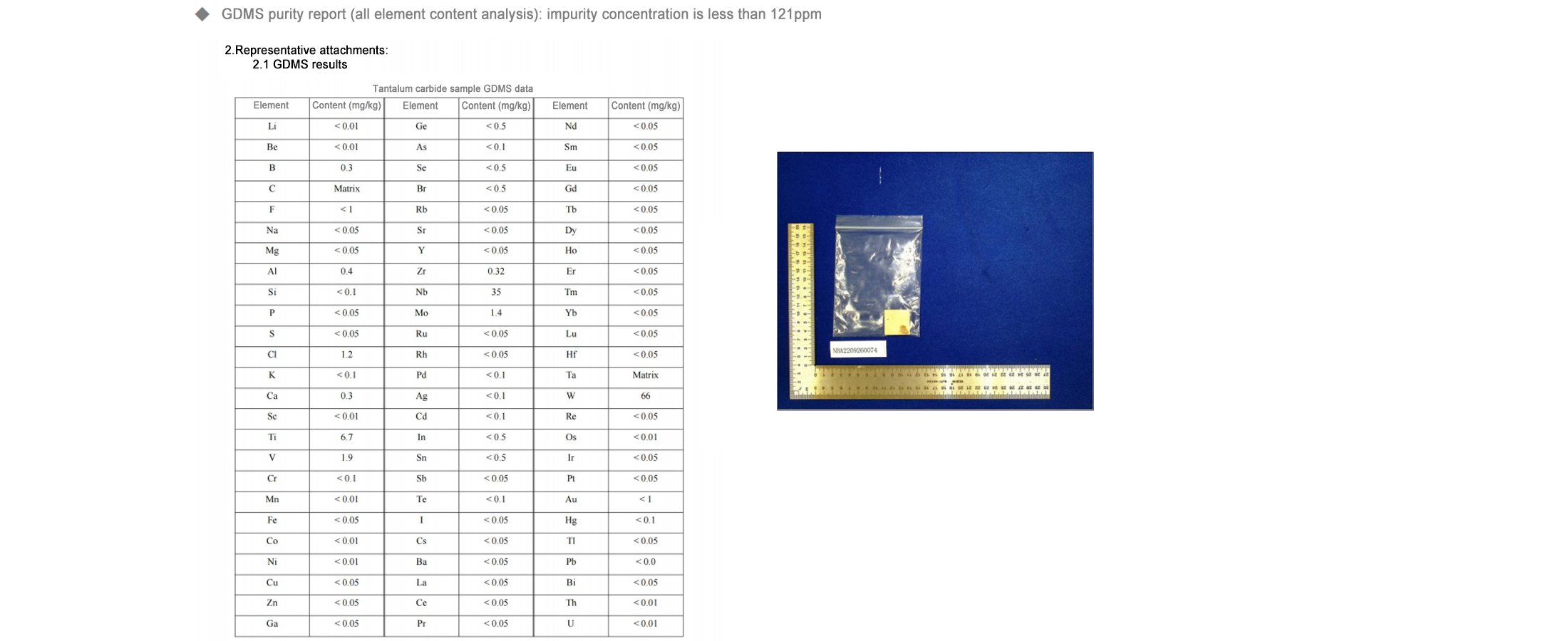

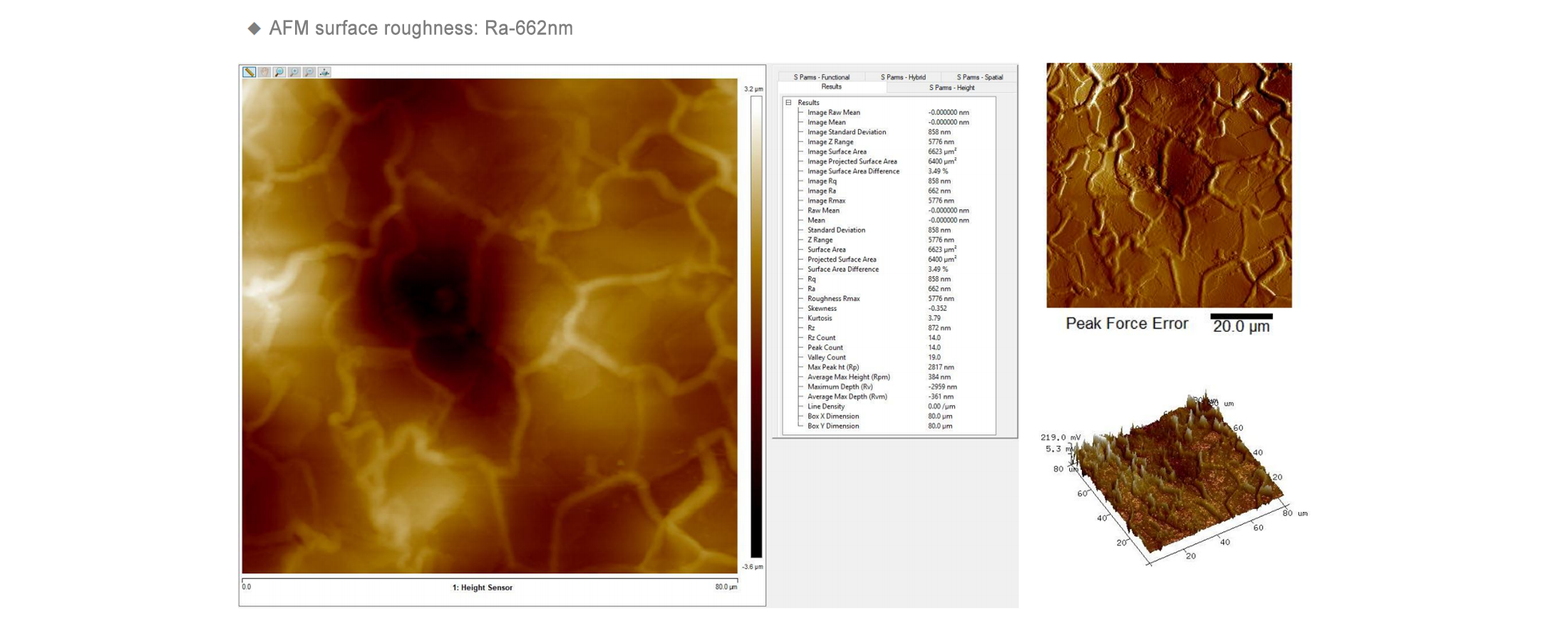

The ọkpụrụkpụ nkeMkpuchi TaCdị ihe dị ka 10-50 μm, ọka na-eto na ntụgharị n'efu, yana TaC nwere usoro cubic nke nwere ihu na-adị otu nkeji, na-enweghị adịghị ọcha ndị ọzọ; mkpuchi ahụ dị oke, usoro ahụ zuru oke, na crystallinity dị elu.Mkpuchi TaCnwere ike mejupụta pores n'elu graphite, ọ na-ejikọta ya na kemịkalụ na matrix graphite na ike njikọ dị elu. Ogo nke Ta na C na mkpuchi dị nso na 1: 1. GDMS nchọta ịdị ọcha ọkọlọtọ ọkọlọtọ ASTM F1593, ntinye adịghị ọcha erughị 121ppm. Usoro mgbakọ na mwepụ pụtara (Ra) nke profaịlụ mkpuchi bụ 662nm.

Ngwa izugbe:

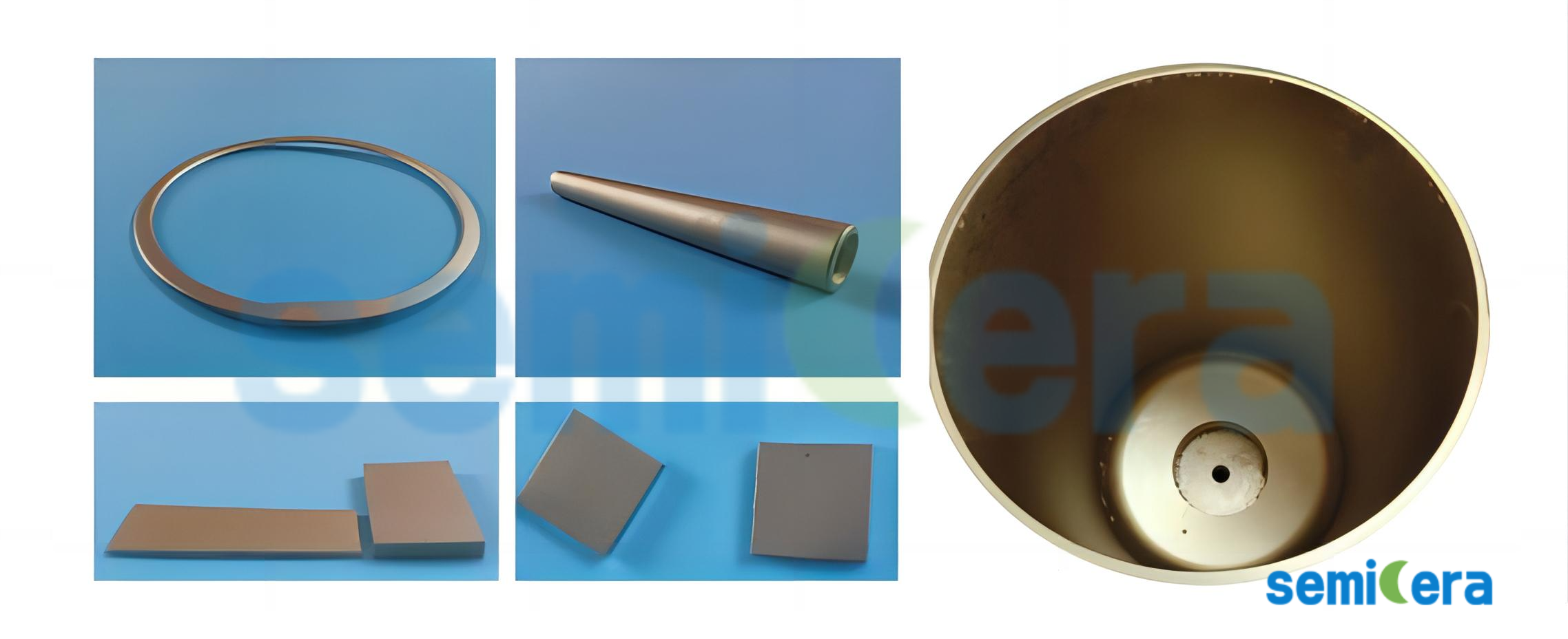

GaN naSiC epitaxialIhe mejupụtara reactor CVD, gụnyere ndị na-ebu wafer, efere satịlaịtị, isi mmiri ịsa ahụ, mkpuchi elu na ihe ndị na-akpata.

Ihe mejupụtara uto kristal SiC, GaN na AlN, gụnyere crucibles, ihe njide kristal mkpụrụ, ntuziaka nzacha na nzacha.

Akụkụ ụlọ ọrụ mmepụta ihe, gụnyere ihe ndị na-ekpo ọkụ na-eguzogide, nozzles, mgbanaka mkpuchi na ihe mgbochi brazing.

Atụmatụ ndị bụ isi:

Akwa okpomọkụ kwụsie ike na 2600 ℃

Na-enye nchedo steeti kwụ ọtọ na gburugburu kemịkalụ siri ike nke H2, NH3, SiH4na Si vapor

Kwesịrị ekwesị maka mmepụta oke na obere usoro mmepụta ihe.