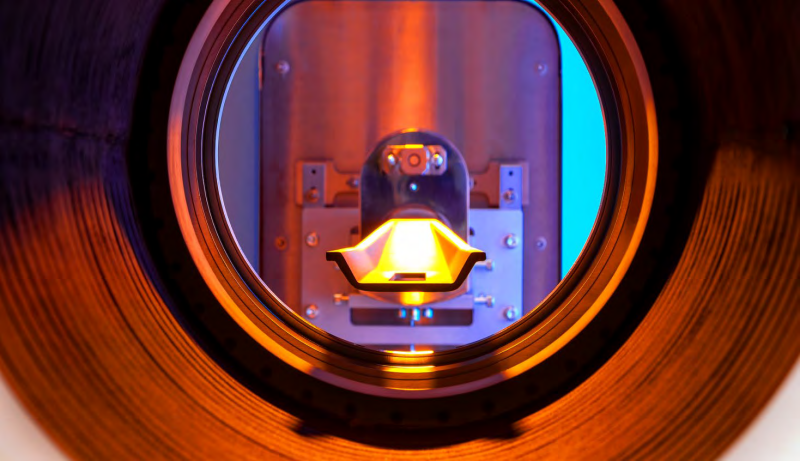

Semicera na-enye omenala dị elusilicon carbide cantilever paddlesemebere ya iji bulie usoro nrụpụta semiconductor. Ihe ohuru ohuruSiC paddleimewe na-eme ka ọ dị ogologo oge na nguzogide dị elu, na-eme ka ọ bụrụ ihe dị mkpa maka njikwa wafer na gburugburu ebe okpomọkụ dị elu.

NkeSilicon carbide paddleEwubere ya ka ọ nagide okirikiri okpomọkụ dị oke egwu ma na-edobe iguzosi ike n'ezi ihe, na-eme ka ụgbọ njem wafer a pụrụ ịdabere na ya n'oge usoro dị oke mkpa nke mmepụta semiconductor. Na elu n'ibu ike, nke aụgbọ mmiri waferna-ebelata ihe ize ndụ nke mmebi nke wafers, na-eduga ná mkpụrụ dị elu na àgwà mmepụta agbanwe agbanwe.

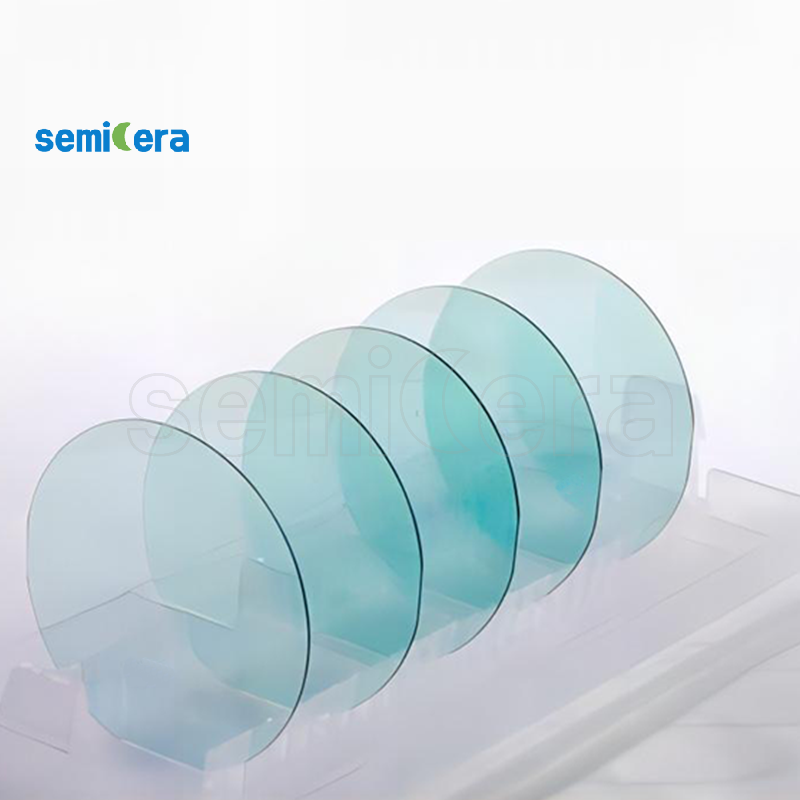

Otu n'ime ihe ọhụrụ ọhụrụ dị na paddle Semicera's SiC dị na nhọrọ imewe omenala ya. Ezubere iji gboo mkpa mmepụta ihe kpọmkwem, paddle ahụ na-enye mgbanwe na ntinye aka na nhazi akụrụngwa dị iche iche, na-eme ka ọ bụrụ ihe ngwọta dị mma maka usoro mmepụta ọgbara ọhụrụ. Ihe owuwu dị fechaa ma sie ike na-enyere aka njikwa dị mfe ma na-ebelata oge arụ ọrụ, na-enye aka n'ịkwalite arụmọrụ na mmepụta semiconductor.

Na mgbakwunye na ya thermal na n'ibu Njirimara, naSilicon carbide paddlena-enye ezigbo nguzogide kemịkalụ, na-enye ya ohere ịrụ ọrụ nke ọma ọbụlagodi na gburugburu kemịkalụ siri ike. Nke a na-eme ka ọ dị mma maka ojiji na usoro metụtara etching, deposition, na ọgwụgwọ okpomọkụ dị elu, ebe ịnọgide na-eguzosi ike n'ezi ihe nke ụgbọ mmiri wafer dị oké mkpa maka ịhụ na mmepụta dị elu.

| Njirimara anụ ahụ nke Silicon Carbide recrystallized | |

| Ngwongwo | Uru a na-ahụkarị |

| Okpomọkụ na-arụ ọrụ (°C) | 1600°C (ya na oxygen), 1700°C (mbelata gburugburu ebe obibi) |

| SiC ọdịnaya | > 99.96% |

| Ọdịnaya Si efu | <0.1% |

| Nnukwu njupụta | 2.60-2.70 g / cm3 |

| Porosity pụtara | <16% |

| Ike mkpakọ | > 600 MPa |

| Ike na-ehulata oyi | 80-90 MPa (20°C) |

| Ike na-ehulata ọkụ | 90-100 MPa (1400°C) |

| Mgbasa ọkụ @1500°C | 4,70 10-6/°C |

| Nrụpụta okpomọkụ @1200°C | 23 W/m•K |

| Modulu nke na-agbanwe agbanwe | 240 GPA |

| Mgbochi ujo okpomọkụ | Dị oke mma |