Ka ọ dị ugbu a, ọgbọ nke atọ nke semiconductors na-achịkwasilicon carbide. N'ime usoro ọnụ ahịa nke ngwaọrụ ya, ihe mejupụtara ya bụ 47%, yana epitaxy na-enweta 23%. Ha abụọ jikọtara ọnụ maka ihe dịka 70%, nke bụ akụkụ kachasị mkpa nkesilicon carbideyinye ụlọ ọrụ na-emepụta ngwaọrụ.

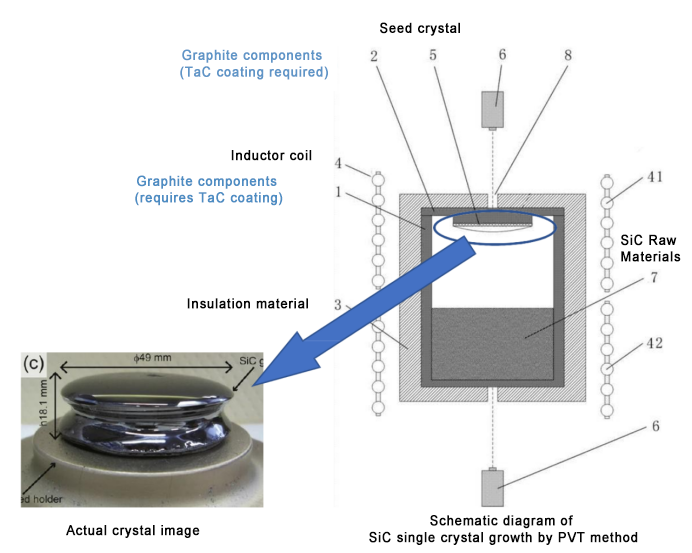

Usoro a na-ejikarị akwadebesilicon carbideotu kristal bụ usoro PVT (ụgbọ njem anụ ahụ). Ụkpụrụ bụ ime ka akụrụngwa na mpaghara okpomọkụ dị elu na kristal mkpụrụ na mpaghara okpomọkụ dị ala. Akụrụngwa na okpomọkụ dị elu na-emebi ma na-emepụta ihe ndị na-emepụta gas na-enweghị mmiri mmiri. A na-ebufe ihe ndị a na-emepụta gas na kristal mkpụrụ n'okpuru mbanye nke gradient axial okpomọkụ, na-emepụta ma na-eto na kristal mkpụrụ iji mepụta otu kristal silicon carbide. Ka ọ dị ugbu a, ụlọ ọrụ ndị mba ọzọ dị ka Cree, II-VI, SiCrystal, Dow na ụlọ ọrụ ụlọ dị ka Tianyue Advanced, Tianke Heda, na Century Golden Core niile na-eji usoro a.

Enwere ihe karịrị ụdị kristal 200 nke silicon carbide, yana njikwa ziri ezi achọrọ iji mepụta otu ụdị kristal achọrọ (nke bụ isi bụ ụdị kristal 4H). Dị ka Tianyue Advanced's prospectus si kwuo, mkpanaka kristal nke ụlọ ọrụ na-amịpụta na 2018-2020 na H1 2021 bụ 41%, 38.57%, 50.73% na 49.90% n'otu n'otu, na ntinye mkpụrụ bụ 72.61%, 75.15%, 75.15%, 75.15% Mmụba zuru oke ugbu a bụ naanị 37.7%. N'iji usoro PVT bụ isi dịka ọmụmaatụ, mkpụrụ dị ala bụ n'ihi ihe isi ike ndị a na nkwadebe mkpụrụ osisi SiC:

1. Ihe isi ike na njikwa mpaghara okpomọkụ: mkpara kristal SiC kwesịrị imepụta ya na oke okpomọkụ nke 2500 ℃, ebe kristal silicon naanị chọrọ 1500 ℃, yabụ achọrọ ọkụ otu kristal pụrụ iche, na uto okpomọkụ kwesịrị ịchịkwa nke ọma n'oge mmepụta. , nke siri ike ịchịkwa.

2. Ngwa ngwa mmepụta ngwa ngwa: Ọnụ ọgụgụ nke ngwa silicon omenala bụ 300 mm kwa elekere, mana silicon carbide single crystals nwere ike itolite 400 microns kwa elekere, nke fọrọ nke nta ka ọ bụrụ ugboro 800 dị iche.

3. Ihe dị elu chọrọ maka parampat ngwaahịa dị mma, na mkpụrụ igbe ojii siri ike ịchịkwa na oge: The isi parameters nke SiC wafers gụnyere microtube njupụta, dislocation njupụta, resistivity, warpage, elu roughness, wdg N'oge kristal ibu usoro, ọ bụ. dị mkpa iji chịkwaa n'ụzọ ziri ezi dị ka silicon-carbon ratio, uto okpomọkụ gradient, kristal uto ọnụego, na ikuku eruba. Ma ọ bụghị ya, ntinye polymorphic nwere ike ime, na-ebute kristal na-erughị eru. N'ime igbe ojii nke graphite crucible, ọ gaghị ekwe omume ịhụ ọkwa uto kristal ozugbo, yana njikwa ebe okpomọkụ nke ọma, ihe dabara na mkpokọta ahụmịhe chọrọ.

4. Ihe isi ike na mgbasawanye kristal: N'okpuru usoro njem ụgbọ ala gas, nkà na ụzụ mgbasawanye nke uto SiC crystal dị oke ike. Ka oke kristal na-abawanye, ihe isi ike uto ya na-abawanye nke ukwuu.

5. N'ozuzu obere mkpụrụ: Low mkpụrụ bụ tumadi esịnede abụọ njikọ: (1) Crystal mkpara mkpụrụ = semiconductor-ọkwa crystal mkpanaka mmepụta / (semiconductor-grade crystal mkpanaka mmepụta + na-abụghị semiconductor-ọkwa crystal mkpara mputa) × 100%; (2) Mkpụrụ mkpụrụ osisi = mmepụta mkpụrụ osisi tozuru etozu/(mpụta mkpụrụ osisi tozuru oke + mmepụta mkpụrụ anaghị eru eru) × 100%.

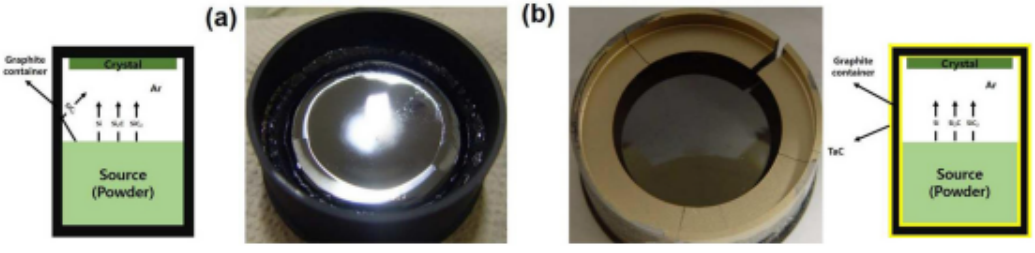

Na nkwadebe nke elu-edu na elu-mkpụrụsilicon carbide mkpụrụ, isi chọrọ mma thermal ubi ihe n'ụzọ ziri ezi ịchịkwa mmepụta okpomọkụ. Ngwa ndị a na-ekpo ọkụ na-ekpo ọkụ nke a na-eji ugbu a bụ akụkụ nhazi graphite dị ọcha dị elu, nke a na-eji kpoo ma gbazee carbon ntụ ntụ na silicon ntụ ntụ ma na-ekpo ọkụ. Ihe eserese nwere njiri mara ike dị elu na modul akọwapụtara nke ọma, nguzogide ujo dị mma na nguzogide corrosion, mana ha nwere ọghọm nke ịdị mfe oxidized na gburugburu ikuku oxygen dị elu, anaghị eguzogide amonia, yana nguzogide na-adịghị mma. Na usoro nke silicon carbide otu kristal ibu nasilicon carbide epitaxial wafermmepụta, o siri ike izute ndị mmadụ na-esiwanye stringent chọrọ maka ojiji nke graphite ihe, nke kpọrọ ihe na-egbochi mmepe ya na ngwa bara uru. Ya mere, mkpuchi okpomọkụ dị elu dị ka tantalum carbide amalitela ịpụta.

2. Njirimara nkeMkpuchi Tantalum Carbide

TaC seramiiki nwere ebe na-agbaze ruo 3880 ℃, ịdị elu siri ike (Mohs hardness 9-10), nnukwu conductivity thermal (22W · m-1 · K-1), nnukwu agbado ike (340-400MPa), na obere mgbasawanye ọkụ. ọnụọgụ (6.6 × 10-6K-1), na-egosipụta nkwụsi ike nke thermochemical dị mma na ihe anụ ahụ mara mma. Ọ nwere ezigbo ndakọrịta kemịkalụ yana ndakọrịta igwe na graphite na ihe mejupụtara C/C. Ya mere, a na-eji mkpuchi TaC eme ihe n'ọtụtụ ebe na nchebe ikuku ikuku, uto otu kristal, ngwa eletriki ike, na akụrụngwa ahụike.

Ekpuchiri TaCgraphite nwere nguzogide corrosion kemịkalụ ka mma karịa graphite efu ma ọ bụ graphite nwere mkpuchi SiC, enwere ike iji ya kwụsie ike na oke okpomọkụ nke 2600 Celsius, yana anaghị emeghachi omume na ọtụtụ ihe ọla. Ọ bụ mkpuchi kachasị mma na ọgbọ nke atọ semiconductor otu uto kristal na ọnọdụ etching wafer. Ọ nwere ike imeziwanye njikwa okpomọkụ na adịghị ọcha na usoro ahụ ma kwadebesilicon carbide wafers dị eluna ndị metụtara yaepitaxial wafers. Ọ dabara nke ọma maka itolite GaN ma ọ bụ AlN otu kristal nwere akụrụngwa MOCVD yana kristal SiC na-eto eto nwere akụrụngwa PVT, yana ogo kristal ndị toro eto na-abawanye nke ọma.

III. Uru nke Ngwa Tantalum Carbide mkpuchi

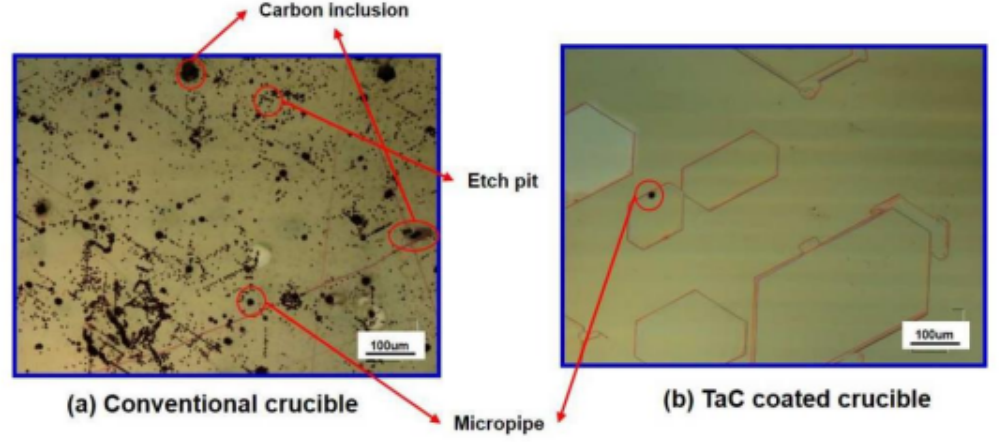

Ojiji nke Tantalum Carbide TaC mkpuchi nwere ike dozie nsogbu nke ntụpọ kristal ma melite ogo kristal. Ọ bụ otu n'ime ntụzịaka ọrụ aka nke "na-eto ngwa ngwa, na-eto eto na ogologo oge". Nnyocha ụlọ ọrụ egosiwokwa na Tantalum Carbide Coated Graphite Crucible nwere ike nweta ọkụ ọkụ ndị ọzọ, si otú ahụ na-enye njikwa usoro dị mma maka uto SiC otu kristal, si otú a na-ebelata ohere nke ịmepụta polycrystalline na nsọtụ kristal SiC. Na mgbakwunye, mkpuchi Tantalum Carbide Graphite nwere uru abụọ bụ isi:

(I) Mbelata ntụpọ SiC

N'ihe gbasara ịchịkwa SiC otu ntụpọ kristal, a na-enwekarị ụzọ atọ dị mkpa. Na mgbakwunye na ịkwalite oke uto na ihe isi mmalite dị elu (dịka ntụ ntụ SiC), iji Tantalum Carbide Coated Graphite Crucible nwekwara ike nweta ezigbo kristal.

Eserese atụmatụ nke graphite crucible (a) na TAC mkpuchi mkpuchi (b)

Dabere na nyocha nke Mahadum Ọwụwa Anyanwụ Europe dị na Korea, isi adịghị ọcha na uto kristal SiC bụ nitrogen, na tantalum carbide mkpuchi graphite crucibles nwere ike belata njikọta nitrogen nke kristal SiC nke ọma, si otú ahụ belata ọgbọ nke ntụpọ dị ka micropipes na ịkwalite kristal. àgwà. Nnyocha egosiwo na n'okpuru otu ọnọdụ ahụ, ndị na-ebu ibu nke SiC wafers toro na graphite crucibles na TAC mkpuchi mkpuchi bụ ihe dịka 4.5 × 1017 / cm na 7.6 × 1015 / cm, n'otu n'otu.

Ntụnyere ntụpọ dị na SiC otu kristal toro na graphite crucibles (a) na TAC mkpuchi mkpuchi (b)

(II) Imelite ndụ nke graphite crucibles

Ka ọ dị ugbu a, ọnụ ahịa kristal SiC ka dị elu, nke ọnụ ahịa ihe eji emepụta graphite bụ ihe dịka 30%. Isi ihe na-ebelata ọnụ ahịa graphite na-eri bụ ịbawanye ndụ ọrụ ya. Dabere na data sitere na otu ndị nyocha Britain, mkpuchi tantalum carbide nwere ike ịgbatị ndụ ọrụ nke akụrụngwa graphite site na 30-50%. Dị ka ngụkọ a si dị, naanị dochie tantalum carbide graphite nwere ike belata ọnụ ahịa kristal SiC site na 9%-15%.

4. Usoro nkwadebe mkpuchi nke Tantalum carbide

Enwere ike kewaa ụzọ nkwadebe mkpuchi TaC ụzọ atọ: usoro siri ike, usoro mmiri mmiri na usoro gas. Usoro nke siri ike na-agụnye usoro mbelata na usoro kemịkalụ; usoro mmiri mmiri na-agụnye usoro nnu gbazere, usoro sol-gel (Sol-Gel), usoro slurry-sintering, usoro ịgbasa plasma; Usoro nke gas na-agụnye ntinye mmiri nke vapor (CVD), chemical vapor infiltration (CVI) na nke anụ ahụ vepor deposition (PVD). Ụzọ dị iche iche nwere uru na ọghọm nke ha. N'ime ha, CVD bụ usoro tozuru oke na nke a na-ejikarị eme ihe maka ịkwadebe mkpuchi TaC. Site na mmụba nke usoro a na-aga n'ihu, usoro ọhụrụ dị ka ntinye kemịkalụ kemịkalụ ikuku na-ekpo ọkụ na ion beam na-enyere aka na ntinye kemịkalụ ikuku emeputala.

Ihe mkpuchi carbon TaC gbanwetụrụ gụnyere graphite, eriri carbon na ihe mejupụtara carbon/carbon. Ụzọ maka ịkwadebe mkpuchi TaC na graphite gụnyere plasma spraying, CVD, slurry sintering, wdg.

Uru nke usoro CVD: Usoro CVD maka ịkwadebe mkpuchi TaC dabere na tantalum halide (TaX5) dị ka isi iyi tantalum na hydrocarbon (CnHm) dị ka isi iyi carbon. N'okpuru ọnọdụ ụfọdụ, a na-ekewa ha na Ta na C n'otu n'otu, wee meghachi omume na ibe ha iji nweta mkpuchi TaC. Enwere ike ịme usoro CVD na obere okpomọkụ, nke nwere ike izere ntụpọ na ibelata ihe ndị na-emepụta ihe na-akpata site na nkwadebe okpomọkụ dị elu ma ọ bụ ọgwụgwọ nke mkpuchi ruo n'ókè ụfọdụ. Ngwakọta na nhazi nke mkpuchi ahụ bụ nke a na-achịkwa, ọ nwekwara uru nke ịdị ọcha dị elu, njupụta dị elu, na nha nha. Nke kachasị mkpa, ihe mejupụtara na nhazi nke mkpuchi TaC nke CVD kwadebere nwere ike ịhazi na ịchịkwa ngwa ngwa. Ọ bụ usoro tozuru oke na nke a na-ejikarị eme ihe maka ịkwadebe mkpuchi TaC dị elu.

Isi ihe na-emetụta usoro a gụnyere:

A. Gas eruba ọnụego (tantalum isi iyi, hydrocarbon gas dị ka carbon isi iyi, ebu gas, dilution gas Ar2, mbenata gas H2): Mgbanwe nke gas eruba ọnụego nwere mmetụta dị ukwuu na okpomọkụ ubi, nrụgide ubi, na gas eruba ubi na. ụlọ mmeghachi omume, na-ebute mgbanwe na nhazi, nhazi, na arụmọrụ nke mkpuchi. Ịba ụba nke ọnụ ọgụgụ Ar ga-ebelata ọnụ ọgụgụ mkpuchi mkpuchi ma belata nha ọka, ebe ọnụ ọgụgụ molar mass nke TaCl5, H2, na C3H6 na-emetụta ihe mkpuchi mkpuchi. Oke molar nke H2 ruo TaCl5 bụ (15-20): 1, nke dabara adaba. Oke molar nke TaCl5 ruo C3H6 dị nso na 3:1. Oke TaCl5 ma ọ bụ C3H6 ga-eme ka e guzobe Ta2C ma ọ bụ carbon efu, na-emetụta ogo wafer.

B. Okpomọkụ nkwụnye ego: Nke dị elu nke okpomọkụ nke nkwụnye ego, ngwa ngwa ntinye ego, na-ebuwanye ibu nke ọka, na mkpuchi mkpuchi. Na mgbakwunye, okpomọkụ na ọsọ nke hydrocarbon decomposition n'ime C na TaCl5 nbibi n'ime Ta dị iche iche, na Ta na C yikarịrị ka ọ ga-etolite Ta2C. Okpomọkụ nwere mmetụta dị ukwuu na mkpuchi TaC gbanwere ihe carbon. Ka ọnọdụ okpomọkụ nke nkwụnye ego na-abawanye, ọnụọgụ ntinye na-abawanye, nha nha na-abawanye, na ọdịdị ahụ na-agbanwe site na okirikiri gaa na polyhedral. Tụkwasị na nke ahụ, ọnụ ọgụgụ dị elu nke okpomọkụ nke nkwụnye ego, ngwa ngwa ngwa ngwa nke TaCl5, nke na-erughị C ga-adị, ka nrụgide dị na mkpuchi ahụ dị ukwuu, na mgbawa ga-adị ngwa ngwa. Otú ọ dị, ọnọdụ okpomọkụ dị ala ga-eduga n'ịrụ ọrụ nkwụnye ego dị ala, ogologo oge nkwụnye ego, na ọnụ ahịa akụrụngwa dị elu.

C. Nrụgide nkwụnye ego: Nrụgide nkwụnye ego nwere njikọ chiri anya na ike efu nke elu ihe ahụ ma na-emetụta oge obibi gas na ụlọ mmeghachi omume, si otú ahụ na-emetụta ngwa ngwa nucleation na nha nha nke mkpuchi. Dị ka ntinye nrụgide na-abawanye, oge obibi gas na-adị ogologo oge, ndị na-emeghachi omume na-enwekwu oge iji nweta mmeghachi omume nucleation, ọnụego mmeghachi omume na-abawanye, ihe ndị ahụ na-ebuwanye ibu, na mkpuchi na-ebuwanye ibu; N'aka nke ọzọ, ka nrụgide nkwụnye ego na-ebelata, oge obibi gas mmeghachi omume dị mkpụmkpụ, mmeghachi omume mmeghachi omume na-ebelata, ihe ndị ahụ na-eme ka ọ dị ntakịrị, na mkpuchi ahụ dị ntakịrị, ma nrụgide nkwụnye ego na-enwe mmetụta dị nta na nhazi kristal na nhazi nke mkpuchi.

V. Mmepe mmepe nke mkpuchi tantalum carbide

Ọnụ ọgụgụ mgbasawanye nke thermal nke TaC (6.6 × 10-6K-1) dịtụ iche na nke ihe ndị sitere na carbon dị ka graphite, carbon fiber, na C / C composite material, nke na-eme ka mkpuchi TaC nke otu oge na-agbawa na mgbawa. na-adapụ. Iji nwetakwuo mma nke ablation na oxidation resistance, elu-okpomọkụ n'ibu nkwụsi ike, na elu okpomọkụ chemical corrosion eguzogide nke TaC coatings, na-eme nnyocha emeela nnyocha na mkpuchi usoro dị ka ihe mejupụtara mkpuchi usoro, siri ike ngwọta-akwalite usoro mkpuchi, na gradient. mkpuchi usoro.

Usoro mkpuchi ihe mejupụtara bụ imechi oghere nke otu mkpuchi. Ọtụtụ mgbe, a na-ewebata ihe mkpuchi ndị ọzọ n'ime elu ma ọ bụ n'ime oyi akwa nke TaC iji mepụta usoro mkpuchi ihe mejupụtara; ihe ngwọta siri ike na-ewusi usoro mkpuchi ike HfC, ZrC, wdg nwere otu ihu na-adabere cubic Ọdịdị dị ka TaC, na abụọ carbides nwere ike infinitely soluble na onye ọ bụla ọzọ na-etolite a siri ike ngwọta Ọdịdị. Ihe mkpuchi Hf (Ta) C enweghị mgbawa ma nwee ezigbo mmachi na ihe mejupụtara C/C. Ihe mkpuchi ahụ nwere ezigbo ọrụ mgbochi ablation; usoro mkpuchi gradient gradient mkpuchi na-ezo aka n'ihe mkpuchi akụrụngwa itinye uche n'akụkụ ntụzịaka ya. Ihe owuwu ahụ nwere ike ibelata nrụgide dị n'ime, melite ndakọrịta nke ọnụọgụ mgbasawanye ọkụ, ma zere mgbawa.

(II) Tantalum carbide mkpuchi ngwaahịa ngwaọrụ

Dị ka ọnụ ọgụgụ na amụma nke QYR (Hengzhou Bozhi), zuru ụwa ọnụ ahịa tantalum carbide mkpuchi ahịa na 2021 ruru US $ 1.5986 nde (ewezuga Cree onwe-emepụta na onwe-ọnọ tantalum carbide mkpuchi ngwaọrụ), na ọ bụ ka na mmalite. ọkwa nke mmepe ụlọ ọrụ.

1. Mgbanaka mgbasawanye kristal na crucibles chọrọ maka uto kristal: Dabere na ọkụ ọkụ kristal 200 maka ụlọ ọrụ ọ bụla, òkè ahịa nke TaC mkpuchi ngwaọrụ chọrọ site na ụlọ ọrụ 30 kristal na-eto eto bụ banyere 4.7 ijeri yuan.

2. TaC tray: tray ọ bụla nwere ike iburu wafer 3, a ga-eji tray ọ bụla mee otu ọnwa, a na-erikwa otu tray maka 100 wafer ọ bụla. 3 nde wafers chọrọ 30,000 TaC trays, tray ọ bụla bụ ihe dị ka 20,000 iberibe, na ihe dị ka nde 600 dị mkpa kwa afọ.

3. Ihe ngosi mbelata carbon ndị ọzọ. Dị ka akwa mkpuchi ọkụ ọkụ, CVD nozzle, ọkpọkọ ọkụ, wdg, ihe dị ka nde 100.

Oge nzipu: Jul-02-2024