Silicon carbide (SiC)ihe nwere uru nke bandgap sara mbara, ịdị elu thermal conductivity, ike mmebi ubi dị oke egwu, yana ngwa ngwa ngwa ngwa elektrọn zuru oke, na-eme ka ọ bụrụ ihe na-ekwe nkwa na mpaghara nrụpụta semiconductor. A na-emepụta otu kristal SiC site na usoro ụgbọ njem anụ ahụ (PVT). Nzọụkwụ kpọmkwem nke usoro a gụnyere itinye SiC ntụ ntụ na ala nke graphite crucible na ịtụkwasị kristal mkpụrụ SiC n'elu crucible. graphitecruciblena-ekpo ọkụ na okpomọkụ dị elu nke SiC, na-eme ka ntụ ntụ SiC na-agbaze n'ime ihe ndị dị na vapor dị ka Si vapor, Si2C, na SiC2. N'okpuru mmetụta nke gradient okpomọkụ axial, ihe ndị a vaporized na-adaba n'elu crucible na condense n'elu nke mkpụrụ osisi SiC, na-egbuke egbuke n'ime otu kristal SiC.

Ugbu a, dayameta nke kristal mkpụrụ a na-ejiSiC otu kristal utokwesịrị dakọtara na dayameta kristal lekwasịrị anya. N'oge uto, a na-edobe kristal mkpụrụ n'elu ihe nkedo nke dị n'elu ihe nkedo na-eji nrapado. Otú ọ dị, usoro a na-edozi kristal mkpụrụ nwere ike ịkpata nsogbu ndị dị ka ihe efu na oyi akwa nrapado n'ihi ihe ndị dị ka nhazi nke elu onye na-ejide mkpụrụ na otu nke mkpuchi mkpuchi, nke nwere ike ịkpata ntụpọ oghere hexagonal. Ndị a na-agụnye imeziwanye ịdị larịị nke efere graphite, na-amụba ịdị n'otu nke ọkpụrụkpụ oyi akwa nrapado, na ịgbakwunye akwa mkpuchi na-agbanwe agbanwe. N'agbanyeghị mbọ ndị a, a ka nwere nsogbu na njupụta nke oyi akwa nrapado, na enwere ihe ize ndụ nke nkwụsị kristal mkpụrụ. Site n'ịgbaso usoro nke njikọta nkewaferna mpempe akwụkwọ graphite ma na-ekpuchi ya n'elu crucible, njupụta nke ihe nkpuchi ahụ nwere ike ime ka ọ dịkwuo mma, a pụkwara igbochi nkwụsị nke wafer.

1. Atụmatụ nnwale:

Wafer ndị a na-eji na nnwale ahụ dị na ahịaỤdị SiC nke anụ ọhịa 6-inch. A na-etinye fotoresis site na iji mkpuchi mkpuchi. A na-enweta adhesion site na iji ọkụ ọkụ na-ekpo ọkụ nke mkpụrụ nke mepụtara onwe ya.

1.1 Atụmatụ ndozi kristal:

Ugbu a, atụmatụ adhesion mkpụrụ kristal SiC nwere ike kewaa ụzọ abụọ: ụdị nrapado na ụdị nkwusioru.

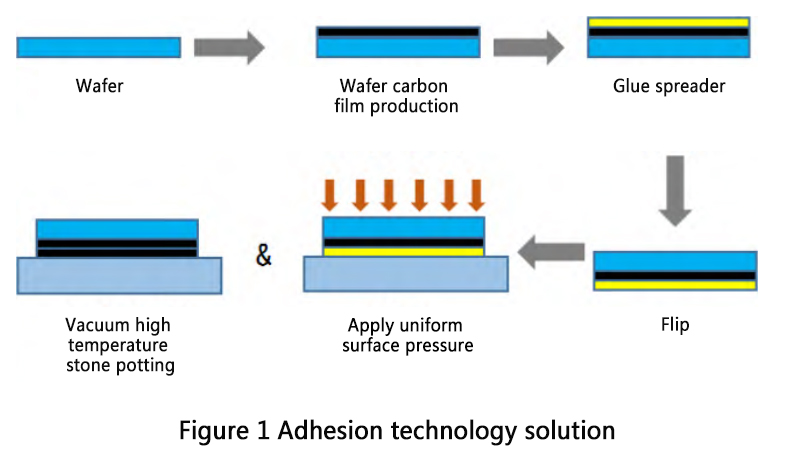

Atụmatụ Ụdị nrapado (Nyocha 1): Nke a gụnyere njikọ nkeSiC waferna graphite efere na oyi akwa nke graphite akwụkwọ dị ka ihe nchekwa oyi akwa ikpochapụ oghere n'etitiSiC waferna efere graphite. Na mmepụta n'ezie, ike njikọ dị n'etiti akwụkwọ graphite na efere graphite adịghị ike, na-eduga n'ịgbapụ mkpụrụ kristal ugboro ugboro n'oge usoro uto okpomọkụ dị elu, na-ebute ọdịda ọdịda.

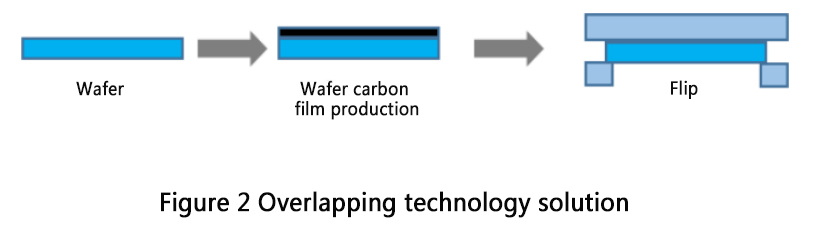

Ụdị nkwusioru (Ọnyonyo 2): A na-emepụta ihe nkiri carbon dị oke n'elu njikọ nke SiC wafer site na iji gluu carbonization ma ọ bụ ụzọ mkpuchi. NkeSiC waferA na-ejikọta ya n'etiti efere graphite abụọ ma tinye ya n'elu graphite crucible, na-eme ka nkwụsi ike mgbe ihe nkiri carbon na-echebe wafer. Otú ọ dị, ịmepụta ihe nkiri carbon site na mkpuchi bụ ọnụ ahịa na-adịghị mma maka mmepụta mmepụta ihe. Usoro gluu carbonization na-arụpụta àgwà ihe nkiri carbon na-ekwekọghị ekwekọ, na-eme ka o sie ike ịnweta ihe nkiri carbon zuru oke nke nwere nrapado siri ike. Na mgbakwunye, ịmachi efere graphite na-ebelata oke uto nke wafer site na igbochi akụkụ nke elu ya.

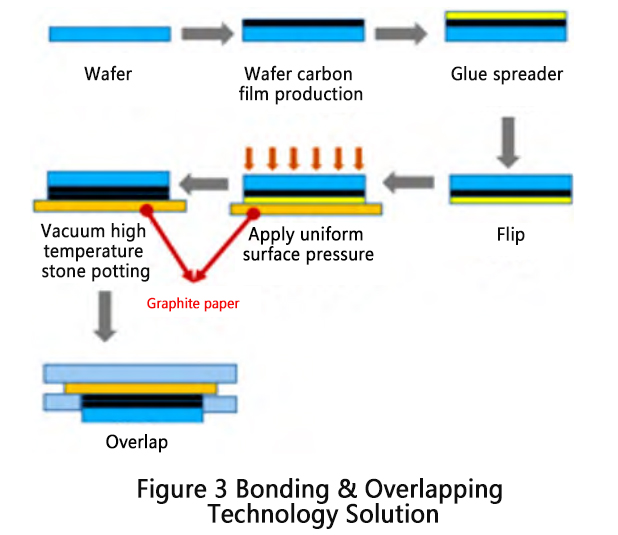

Dabere na atụmatụ abụọ a dị n'elu, a na-atụpụta atụmatụ nrapado na nkpuchi ọhụrụ (Nkeji 3):

A na-emepụta ihe nkiri carbon dị ntakịrị n'elu njikọ nke SiC wafer site na iji usoro gluu carbonization, na-ahụ na ọ dịghị nnukwu ntapu ọkụ n'okpuru ọkụ.

A na-ejikọta wafer SiC nke ejiri ihe nkiri carbon kpuchie ya na akwụkwọ graphite, ebe njikọ dị n'elu bụ akụkụ ihe nkiri carbon. Ngwunye nrapado kwesịrị ịpụta otu oji n'okpuru ìhè.

A na-amachi akwụkwọ graphite site na efere graphite ma kwụsịtụrụ n'elu graphite crucible maka uto kristal.

1.2 Nrapado:

The viscosity nke photoresist budata emetụta film ọkpụrụkpụ uniformity. N'otu ọsọ ọsọ ahụ, viscosity dị ala na-ebute ihe nkiri nrapado dị gịrịgịrị na otu. Ya mere, a na-ahọrọ fotoresist dị ala viscosity n'ime ihe ngwa chọrọ.

N'oge nnwale ahụ, a chọpụtara na viscosity nke nrapado carbonizing na-emetụta ike njikọ dị n'etiti ihe nkiri carbon na wafer. Nnukwu viscosity na-eme ka o sie ike itinye n'otu n'otu site na iji mkpuchi mkpuchi, ebe viscosity dị ala na-ebute ike njikọ na-adịghị ike, na-eduga n'ịgbawa ihe nkiri carbon n'oge usoro njikọ na-esote n'ihi nrapado na nrụgide mpụga. Site na nyocha nnwale, viscosity nke nrapado carbonizing kpebiri na ọ ga-abụ 100mPa·s, na viscosity nrapado njikọ ka edobere na 25 mPa·s.

1.3 Igwe anaghị arụ ọrụ:

Usoro nke ịmepụta ihe nkiri carbon na SiC wafer gụnyere carbonizing oyi akwa nrapado n'elu SiC wafer, nke a ga-emerịrị na oghere ma ọ bụ gburugburu ebe nchekwa argon. Nsonaazụ nnwale na-egosi na gburugburu ebe nchekwa argon dị mma maka imepụta ihe nkiri carbon karịa ebe ikuku dị elu. Ọ bụrụ na a na-eji ebe na-ekpo ọkụ eme ihe, ọkwa oghere kwesịrị ịbụ ≤1 Pa.

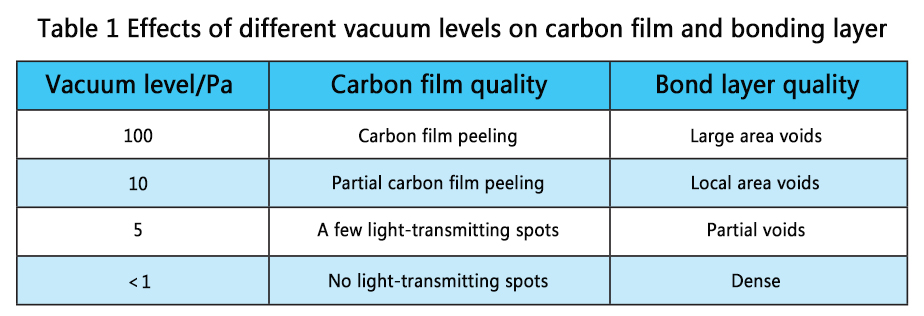

Usoro ijikọ mkpụrụ kristal SiC gụnyere ijikọ wafer SiC na mpempe graphite. N'iburu n'uche mmetụta na-adịghị mma nke ikuku oxygen na ihe ndị graphite na okpomọkụ dị elu, a ghaghị ime usoro a n'okpuru ọnọdụ oghere. A mụrụ mmetụta nke ọkwa oghere dị iche iche na oyi akwa nrapado. E gosipụtara nsonaazụ nnwale ahụ na Tebụl 1. Enwere ike ịhụ na n'okpuru ọnọdụ oghere dị ala, a naghị ewepụ mkpụrụ ndụ oxygen na ikuku kpamkpam, na-eduga n'ọkwa nrapado na-ezughị ezu. Mgbe oghere oghere dị n'okpuru 10 Pa, mmetụta na-emerụ ahụ nke ụmụ irighiri ikuku oxygen na oyi akwa nrapado na-ebelata nke ukwuu. Mgbe ọkwa oghere dị n'okpuru 1 Pa, a na-ewepụ mmetụta na-emerụ ahụ kpamkpam.

Oge nzipu: Jun-11-2024