Okpokoro oxide thermal oxide nke silicon wafer bụ oyi akwa oxide ma ọ bụ oyi akwa silica nke kpụrụ n'elu elu nke silicon wafer n'okpuru ọnọdụ okpomọkụ dị elu nke nwere ihe na-emepụta ihe.The thermal oxide oyi akwa nke silicon wafer na-emekarị toro na a kehoraizin tube ọkụ, na ibu okpomọkụ nso bụ n'ozuzu 900 Celsius C ~ 1200 Celsius C, na e nwere abụọ ibu ụdịdị nke "mmiri oxidation" na "akọrọ oxidation".Okpokoro oxide thermal bụ oyi akwa oxide “toro” nke nwere homogeneity dị elu yana ike dielectric dị elu karịa oyi akwa oxide edobere CVD.Thermal oxide oyi akwa bụ ezigbo dielectric oyi akwa dị ka insulator.N'ọtụtụ ngwaọrụ dabere na silicon, oyi akwa thermal oxide na-arụ ọrụ dị mkpa dị ka oyi akwa mgbochi doping na dielectric elu.

Ndụmọdụ: Ụdị oxidation

1. Akọrọ oxidation

Silikoni na-emeghachi omume na oxygen, na oyi akwa oxide na-aga n'ihu oyi akwa basal.A ghaghị ime oxidation akọrọ na okpomọkụ nke 850 ruo 1200 Celsius C, ọnụ ọgụgụ na-eto eto dị ala, nke a pụrụ iji mee ihe maka MOS mkpuchi ọnụ ụzọ ámá.Mgbe ịdị mma dị elu, achọrọ oyi akwa silicon oxide dị nro, a na-ahọrọ oxidation akọrọ karịa mmiri oxidation.

Ike oxidation akọrọ: 15nm ~ 300nm (150A ~ 3000A)

2. Mmiri oxidation

Usoro a na-eji ngwakọta nke hydrogen na ikuku oxygen dị elu na-ere ọkụ na ~ 1000 Celsius, si otú a na-emepụta mmiri mmiri na-emepụta oyi akwa oxide.Ọ bụ ezie na mmiri oxidation enweghị ike ịmepụta dị ka elu àgwà oxidation oyi akwa dị ka akọrọ oxidation, ma ezuru iji dị ka ebe dịpụrụ adịpụ, tụnyere akọrọ oxidation nwere doro anya uru bụ na ọ nwere elu ibu ọnụego.

Ike oxidation mmiri: 50nm ~ 15µm (500A ~ 15µm)

3. Usoro akọrọ - usoro mmiri - usoro akọrọ

N'ime usoro a, a na-ahapụ ikuku oxygen dị ọcha n'ime ọkụ oxidation na mbido mbụ, a na-agbakwunye hydrogen n'etiti oxidation, na hydrogen na-echekwa na njedebe iji nọgide na-ekpo ọkụ na ikuku oxygen dị ọcha iji mepụta usoro oxidation denser karịa. usoro oxidation mmiri na-emekarị n'ụdị uzuoku mmiri.

4. TEOS oxidation

| Usoro Oxidation | Mmiri oxidation ma ọ bụ akọrọ oxidation |

| Dayameta | 2″ / 3″ / 4″ / 6″ / 8″ / 12″ |

| Ọkpụrụkpụ Oxide | 100 Å ~ 15µm |

| Ndidi | +/- 5% |

| Elu | Otu akụkụ Oxidation (SSO) / Oxidation akụkụ abụọ (DSO) |

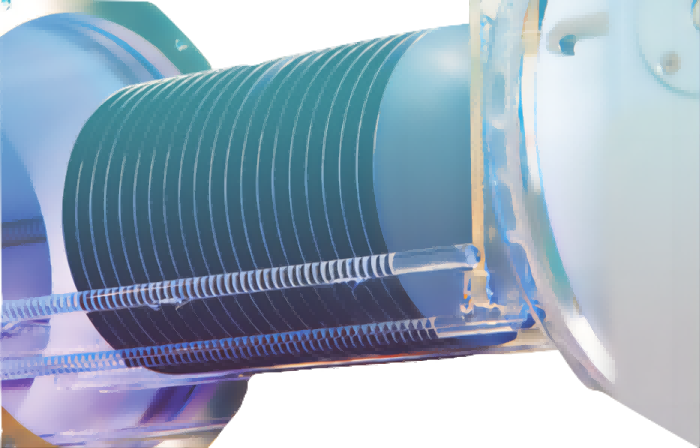

| Igwe ọkụ | Igwe ọkụ tube kwụ ọtọ |

| Gas | Hydrogen na ikuku oxygen |

| Okpomọkụ | 900 ℃ ~ 1200 ℃ |

| Ntụgharị ntụgharị | 1.456 |